Lithium ion adsorption column and preparation method thereof

A lithium ion, adsorption column technology, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve problems such as poor fluidity and permeability, increased resistance of fixed bed, and difficulty in industrialization of lithium extraction. To achieve the effect of stable flow, fast adsorption rate and constant resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

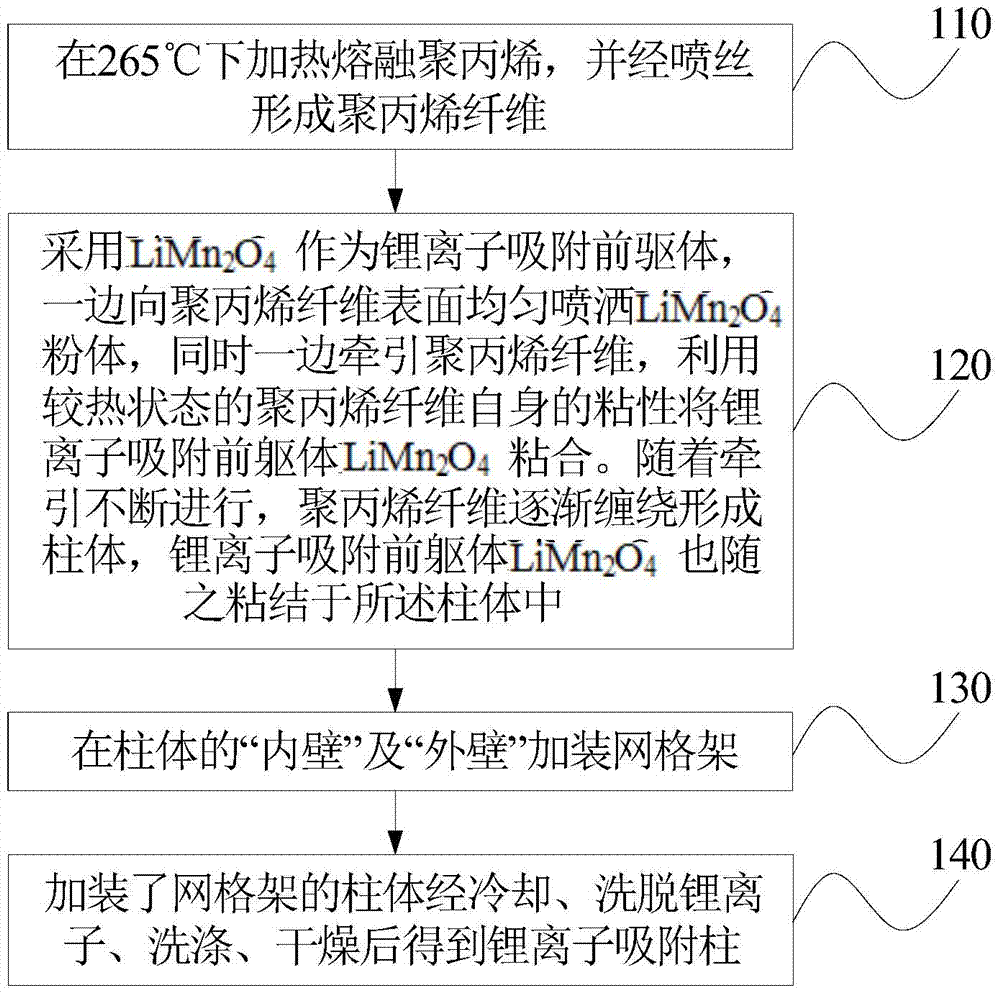

Embodiment 1

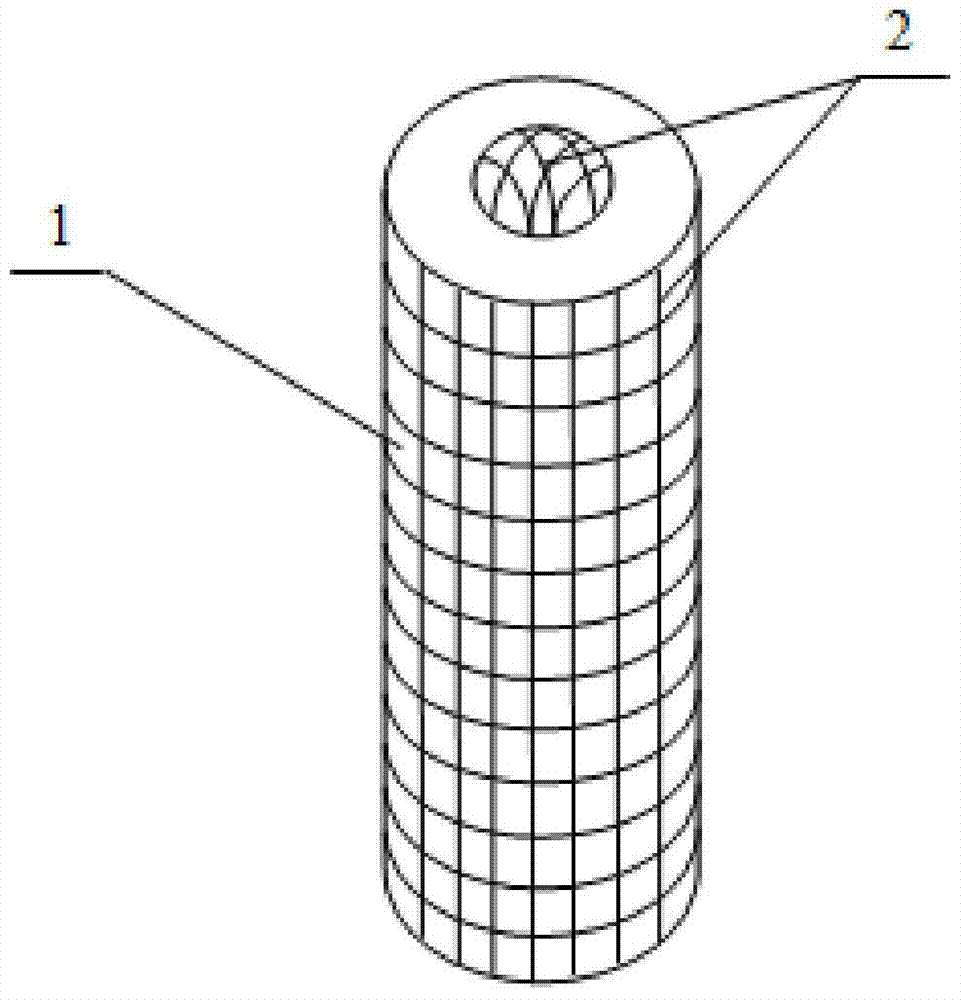

[0027] refer to figure 1 , the lithium ion adsorption column of this embodiment includes a column formed by entanglement of thermoplastic polymer fibers, and a lithium ion adsorbent is bonded in the column; wherein, the lithium ion adsorbent consists of a lithium ion adsorption precursor Obtained after elution of lithium ions.

[0028] Preferably, a grid frame is also installed on the column to increase the structural strength and pressure resistance of the column. The structure diagram of the obtained lithium ion adsorption column is as follows figure 1 As shown, wherein, 1 is a lithium ion adsorption column, and 2 is a grid frame.

[0029] This kind of lithium ion adsorption column uses thermoplastic polymer fibers to form a column, which not only makes the column have a huge specific surface area, increases the interaction area between the adsorbent and brine on the column, and improves the adsorption efficiency; It can be shaped in any shape or size, which is convenient ...

Embodiment 2

[0045] In the description of Embodiment 2, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between embodiment 2 and embodiment 1 is that in step 110, polytetrafluoroethylene is melted at 400°C to form polytetrafluoroethylene fibers; in step 120, Li 2 Ti 3 o 7 As a lithium ion adsorption precursor, while spraying Li uniformly on the surface of PTFE fibers 2 Ti 3 o 7 Powder, while pulling the PTFE fiber, using the viscosity of the PTFE fiber itself in the hotter state to adsorb lithium ions on the precursor Li 2 Ti 3 o 7 bonding. As the traction continues, the polytetrafluoroethylene fibers are gradually entangled to form a column, and the lithium ion adsorbs the precursor Li 2 Ti 3 o 7 It is also bonded in the column; among them, Li 2 Ti 3 o 7 The mass ratio with polytetrafluoroethylene is 0.75:1; In step 130, on the "inner wall" and "outer wall" of the cylinder, the stainles...

Embodiment 3

[0048] In the description of Embodiment 3, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between embodiment 3 and embodiment 1 is that in step 110, polyethylene is melted at 160°C to form polyethylene fibers; in step 120, Li 1.6 mn 1.6 o 4 As a lithium ion adsorption precursor, while spraying Li evenly on the surface of polyethylene fibers 1.6 mn 1.6 o 4 powder, while pulling the polyethylene fiber, using the viscosity of the polyethylene fiber itself in a relatively hot state to adsorb lithium ions to the precursor Li 1.6 mn 1.6 o 4 bonding. As the traction continues, the polyethylene fibers are gradually entangled to form a column, and the lithium ion adsorbs the precursor Li 1.6 mn 1.6 o 4 It is also bonded in the column; among them, Li 1.6 mn 1.6 o 4 The mass ratio with polyethylene is 1:1; In step 130, on the "inner wall" and "outer wall" of the cylinder, the stainles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com