Preparation method of glass substrate graphene/silver nano wire transparent conductive film

A transparent conductive film and silver nanowire technology, applied in the chemical field, can solve the problems of high cost, rising indium price, expensive ITO materials, etc., achieve high uniformity and stability, improve conductivity, and avoid cumbersome effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) The expanded graphite is prepared by the Hummers method to obtain an aqueous graphite oxide solution. Obtained stable dispersed graphene oxide colloid (2mg / ml) through ultrasonic treatment for 25min;

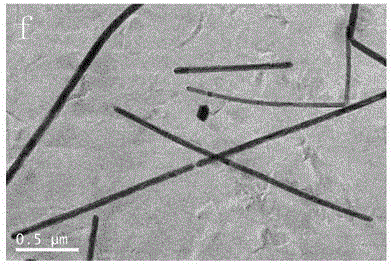

[0015] (2) Mix the same volume (10ml) and concentration (0.1M) of sodium citrate and silver nitrate aqueous solution in a single-necked flask, and then add 162ml of graphene oxide (GO) and 10ml of N-N dimethylacetamide. Use a magnetic stirrer to react at room temperature in the dark for 12 h. Raise the temperature to 130°C for 3h. Then add 3.24g of sodium citrate, adjust the pH to ≈12 with ammonia water, and keep the temperature down to 95°C for 6 hours. Wash the product by centrifugation with ethanol, prepare a 1 mg / ml silver nanowire / graphene hybrid solution and store it in a jar as a precursor for later use;

[0016] (3) Choose a glass sheet with a side length of 2cm and a thickness of 2.5mm and soak it in a solution of concentrated sulfuric acid (98%):hydrogen ...

Embodiment 2

[0020](1) The expanded graphite is prepared by the Hummers method to obtain an aqueous graphite oxide solution. After 27min of ultrasonic treatment, a stable dispersed graphene oxide colloid (2.5mg / ml) was obtained;

[0021] (2) Mix equal volume (12ml); equal concentration (0.2M) of sodium citrate and silver nitrate aqueous solution in a single-necked flask, then add 312ml of graphene oxide (GO) aqueous solution and 12ml of N-N dimethyl ethyl ether Amide solution. Use a magnetic stirrer to react at room temperature in the dark for 12 h. Raise the temperature to 130°C for 3h. Then add 7.8g of sodium citrate, adjust the pH of the solution to ≈12 with ammonia water, and lower the temperature to 95°C for 6 hours. The product was centrifuged and washed with ethanol, and a 1.2 mg / ml silver nanowire / graphene hybrid solution was prepared in a jar. As a precursor for later use;

[0022] (3) Choose a glass piece with a side length of 2.5cm and a thickness of 2.5mm and soak it in a ...

Embodiment 3

[0026] (1) Prepare graphite oxide aqueous solution by Hummers method. After 29min of ultrasonic treatment, a stable dispersed graphene oxide colloid (3mg / ml) was obtained;

[0027] (2) Mix an equal volume (12ml) and an equal concentration (0.3M) of sodium citrate and silver nitrate aqueous solution in a single-necked flask, then add 390ml of graphene oxide (GO) aqueous solution and 12ml of N-N dimethyl ethyl ether Amide solution. Use a magnetic stirrer to react at room temperature in the dark for 12 h. The temperature was raised to 130°C for 3 hours. Then add 11.66g of sodium citrate, adjust the pH of the solution to ≈12 with ammonia water, and lower the temperature to 95°C for 6 hours. The product was centrifuged and washed with ethanol, and a 1.2 mg / ml silver nanowire / graphene hybrid solution was prepared in a jar. As a precursor for later use;

[0028] (3) Choose a glass sheet with a side length of 3cm and a thickness of 2.5mm and soak it in a solution of concentrated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com