A tunable optical micro-cavity Raman laser and a tunable optical micro-cavity doped laser

A Raman laser and optical microcavity technology, applied in the field of lasers, can solve the problems of inability to develop and apply large-scale integration, high relative intensity noise, and high threshold, and achieve large-scale development and application, low relative intensity noise, Simple effect of tuning mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

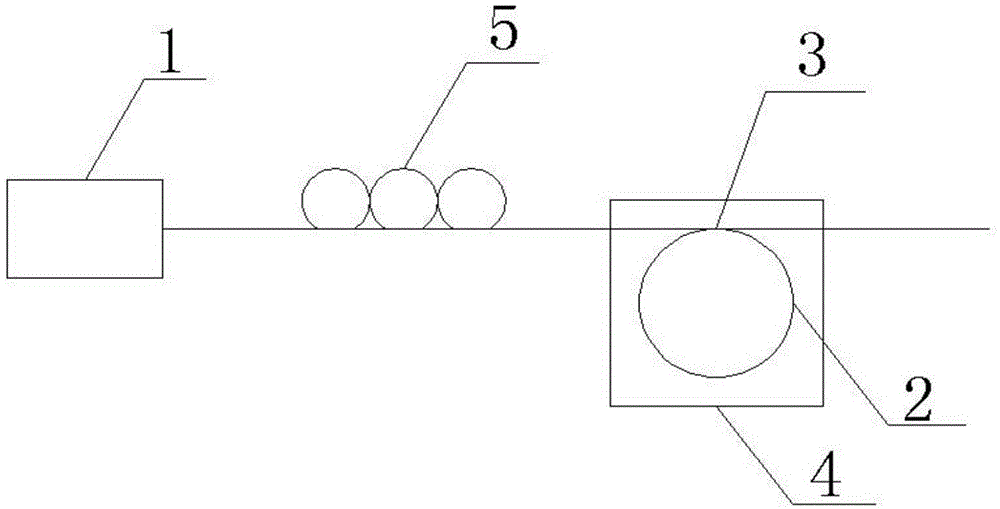

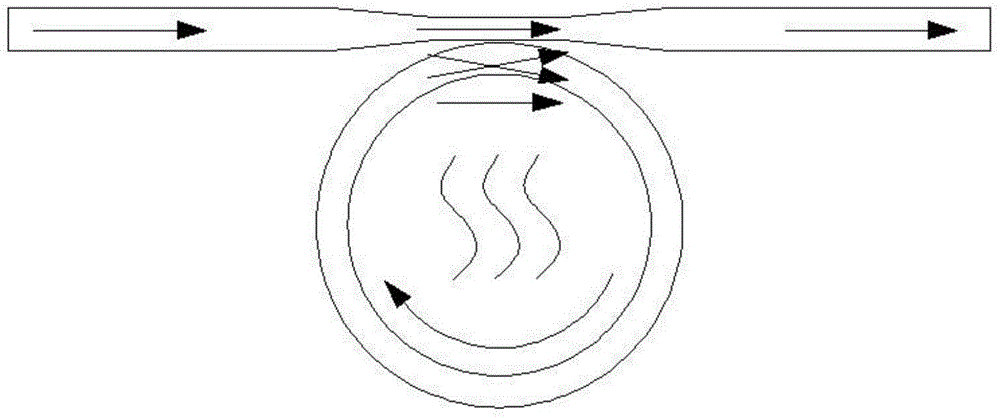

[0042] Micro-annular optical micro-cavity tuning principle

[0043] The resonant wavelength of the microring optical microcavity can be written in the form of Equation 1

[0044] λ M = 2 πRn e f f M - - - ( 1 )

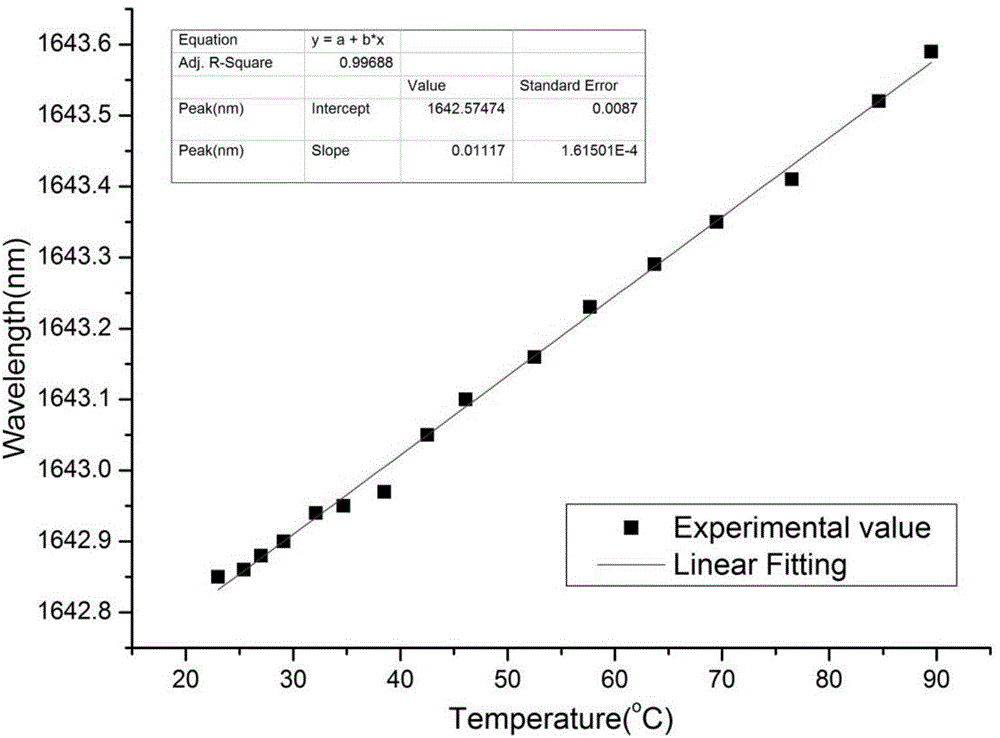

[0045] lambda M is the wavelength in vacuum of the laser in the M (M is a positive integer) order resonance mode, R is the radius of the microdisk, n eff is the effective refractive index of the whispering gallery mode. By changing the resonant wavelength condition in Equation 1, the resonant output wavelength in the gain spectrum can be changed to realize the tuning of the output wavelength of the laser. When the temperature of the microcavity changes, both the microcavity volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com