A kind of titanium silicon molecular sieve and preparation method thereof

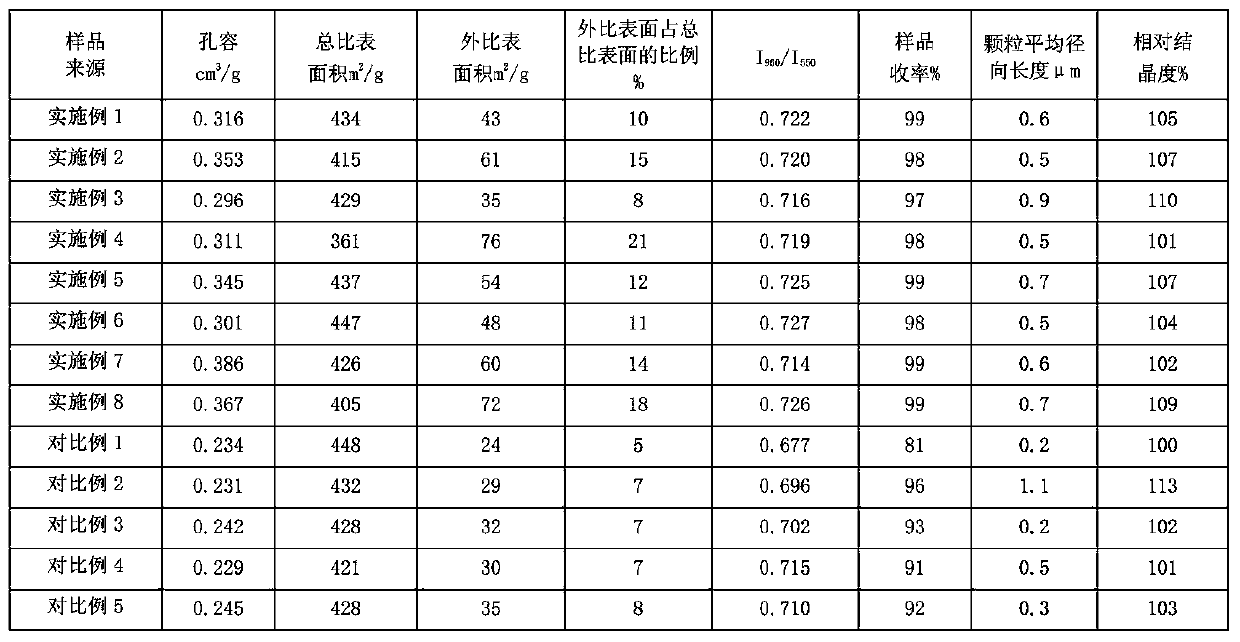

A titanium-silicon molecular sieve and silicon source technology, applied in the direction of crystalline aluminosilicate zeolite, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as complex process, insufficient reactivity, and small grain size , to achieve the effects of increased selectivity, full play of oxidation activity, and increased relative crystallinity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 20 grams of silicon source tetraethyl orthosilicate to tetrapropyl ammonium hydroxide aqueous solution and stir to mix evenly, then add tetrabutyl titanate and mix evenly to obtain the molar composition: silicon source: titanium source: alkali source: Water = 100:2:15:1000 mixture, wherein the silicon source is SiO 2 Meter, titanium source as TiO 2 In terms of, the alkali source is in terms of N or OH-. Put the mixture in a sealed stainless steel reaction kettle, raise the temperature of the kettle from room temperature to 100°C at a heating rate of 2°C / min and perform hydrothermal treatment at this temperature for 24 hours, and then raise the temperature of the kettle to 190°C at a heating rate of 15°C / min And hydrothermal treatment at this temperature for 6 hours; then reduce the temperature of the kettle to 170 °C at a cooling rate of 10 °C / min and hydrothermal treatment at this temperature for 48 hours, and finally cool down to room temperature and release the ...

Embodiment 2

[0060] Add 20 grams of silicon source solid silicon source white carbon black to tetrapropyl ammonium hydroxide aqueous solution and stir to mix evenly, then add tetrabutyl titanate and mix evenly to obtain the molar composition: silicon source: titanium source: alkali source: Water = 100:1:20:600 mixture, wherein the silicon source is SiO 2 Meter, titanium source as TiO 2 In terms of, the alkali source is in terms of N or OH-. Put the mixture in a sealed stainless steel reaction kettle, raise the temperature of the kettle from room temperature to 90°C at a heating rate of 10°C / min, and conduct hydrothermal treatment at this temperature for 12 hours, and then raise the temperature of the kettle to 190°C at a heating rate of 20°C / min And hydrothermal treatment at this temperature for 4 hours; then reduce the temperature of the kettle to 170 ° C at a cooling rate of 20 ° C / min and hydrothermal treatment at this temperature for 36 hours, and finally cool down to room temperatu...

Embodiment 3

[0064] Add 20 grams of silicon source tetraethyl orthosilicate to tetrapropyl ammonium hydroxide aqueous solution and stir to mix evenly, then add titanium sulfate and mix evenly to obtain the molar composition: silicon source: titanium source: alkali source: water = 100 : 4:10:1500 mixture, wherein the silicon source is SiO 2 Meter, titanium source as TiO 2 In terms of, the alkali source is in terms of N or OH-. Put the mixture in a sealed stainless steel reaction kettle, raise the temperature of the kettle from room temperature to 100°C at a temperature increase rate of 1°C / min and perform hydrothermal treatment at this temperature for 24 hours, and then raise the temperature of the kettle to 180°C at a temperature increase rate of 10°C / min And hydrothermal treatment at this temperature for 6 hours; then reduce the temperature of the kettle to 150 ° C at a cooling rate of 5 ° C / min and hydrothermal treatment at this temperature for 48 hours, and finally cool down to room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com