Comprehensive resourceful treatment device and method for chlorohydric acid pickling waste liquid

A technology of pickling waste liquid and comprehensive resources, applied in metallurgical wastewater treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of high process and equipment requirements, large initial investment, high evaporation temperature, etc., to achieve Taking into account both environmental benefits and economic benefits, reducing environmental pollution hazards, and low investment and disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

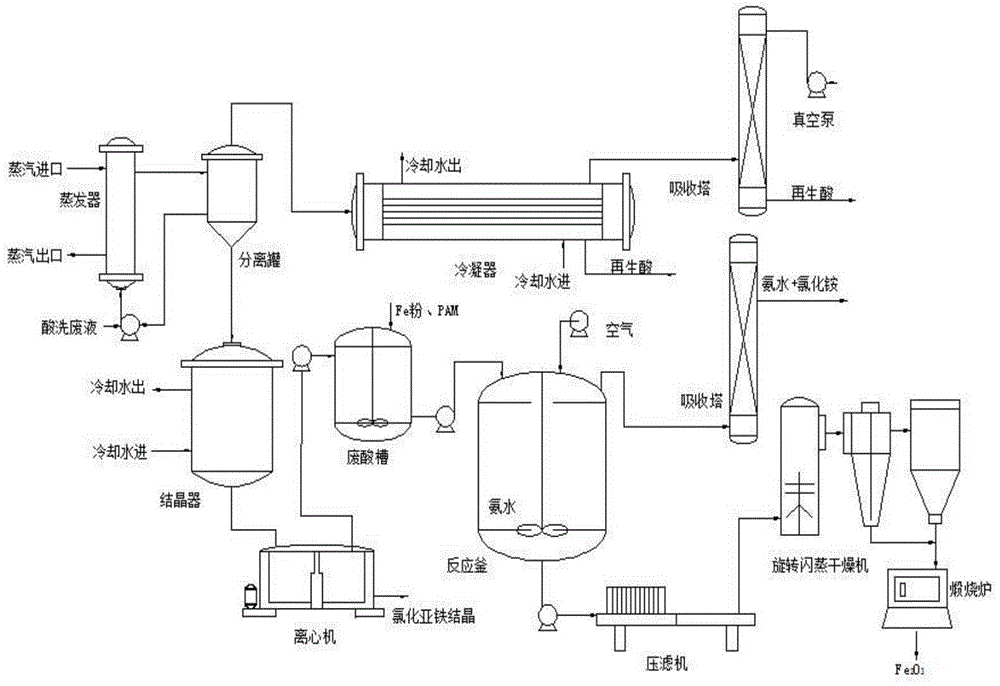

Image

Examples

Embodiment 1

[0022] Step 1: Negative pressure evaporation process

[0023] Negative pressure evaporation is carried out on the pickling waste liquid, and the condensed distillate is collected as regenerated hydrochloric acid

[0024] Put 1 ton of hydrochloric acid pickling waste liquid in the evaporator after filtering to remove large particles of impurities, pass in steam, and carry out negative pressure evaporation under the best operating conditions, that is, the vacuum degree is 0.06MPa, the reaction temperature is 88°C, and the waste liquid Evaporation is 50%. The evaporated HCl gas is condensed and recovered by the condensing device to obtain regenerated hydrochloric acid with a mass fraction of about 10%. The tail gas of the condenser is absorbed by circulating tap water spray, and when the concentration of hydrochloric acid in the absorption liquid reaches 5%, it is replaced and recycled as a pickling process Hydrochloric acid diluted with water.

[0025] Step 2: Evaporate the mo...

Embodiment 2

[0032] Step 1: Negative pressure evaporation process

[0033] Negative pressure evaporation is carried out on the pickling waste liquid, and the condensed distillate is collected as regenerated hydrochloric acid

[0034] Put 1 t of hydrochloric acid pickling waste liquid in the evaporator after filtering to remove large particles of impurities, and carry out negative pressure evaporation under the optimal operating conditions described in Example 1 to obtain regenerated hydrochloric acid with a mass fraction of about 10%. The HCl gas that comes out is condensed and recovered by the condensing device, and the tail gas of the condenser is sprayed and absorbed with tap water circulation, and when the concentration of hydrochloric acid in the absorption liquid reaches 5%, it is replaced and recovered as water for diluting hydrochloric acid in the pickling process.

[0035] Step 2: Evaporate the mother liquor and cool and crystallize

[0036] Cool the evaporated distillation mothe...

Embodiment 3

[0042] Step 1: Negative pressure evaporation process

[0043] In the negative pressure evaporation process, the pickling waste liquid is evaporated under negative pressure, and the condensed distillate is collected as regenerated hydrochloric acid

[0044] Put 1 t of hydrochloric acid pickling waste liquid in the evaporator after filtering to remove large particles of impurities, and carry out negative pressure evaporation under the optimal operating conditions described in Example 1 to obtain regenerated hydrochloric acid with a mass fraction of about 10%. The HCl gas that comes out is condensed and recovered by the condensing device, and the tail gas of the condenser is sprayed and absorbed with tap water circulation, and when the concentration of hydrochloric acid in the absorption liquid reaches 5%, it is replaced and recovered as water for diluting hydrochloric acid in the pickling process.

[0045] Step 2: Evaporate the mother liquor and cool and crystallize

[0046] Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com