Acrylic-acid-modified water-based alkyd resin and preparation method thereof

A technology of water-based alkyd resin and acrylic acid, which is applied in coatings, polyester coatings, etc., can solve the problems of waterproof, weather resistance, acid and alkali resistance, large ethylene glycol waste base, high cost, etc., so as to facilitate the reaction The effect of progress, low cost and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

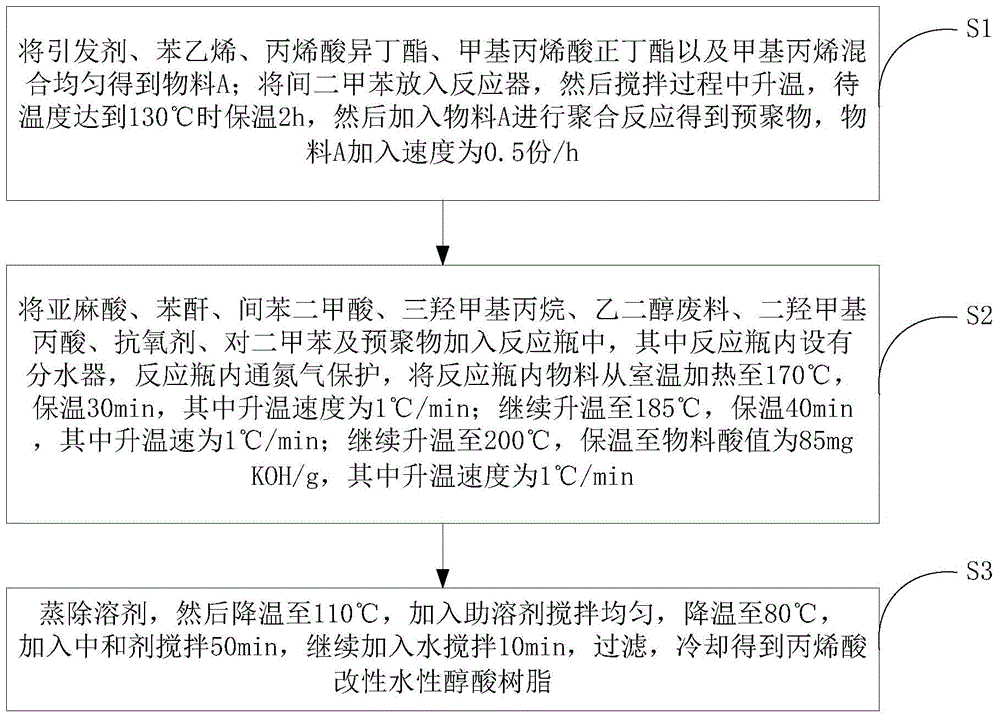

Method used

Image

Examples

Embodiment 1

[0021] A kind of acrylic modified water-based alkyd resin, its raw material comprises by weight: 20 parts of m-xylene, 4 parts of styrene, 3 parts of ethylene glycol waste, 0.3 parts of initiator, 10 parts of isobutyl acrylate, n-methacrylic acid 4 parts of butyl ester, 0.5 parts of methacrylic acid, 60 parts of dehydrated castor oil, 10 parts of phthalic anhydride, 4 parts of isophthalic acid, 4 parts of trimethylol propane, 30 parts of dimethylol propionic acid, anti 1 part of oxygen agent, 30 parts of cosolvent, 10 parts of neutralizer, 20 parts of p-xylene, 15 parts of water;

Embodiment 2

[0023] A kind of acrylic acid modified waterborne alkyd resin, its raw material comprises by weight: m-xylene 30 parts, styrene 2 parts, ethylene glycol waste 5 parts, initiator 0.2 part, isobutyl acrylate 15 parts, methacrylic acid 3 parts of n-butyl ester, 1 part of methacrylic acid, 50 parts of dehydrated castor oil, 15 parts of phthalic anhydride, 1 part of isophthalic acid, 6 parts of trimethylol propane, 20 parts of dimethylol propionic acid, 3 parts of antioxidant, 20 parts of cosolvent, 15 parts of neutralizer, 10 parts of p-xylene, 20 parts of water;

Embodiment 3

[0025] A kind of acrylic acid modified waterborne alkyd resin, its raw material comprises by weight: 25 parts of m-xylene, 3.6 parts of styrene, 4 parts of ethylene glycol waste, 0.28 part of initiator, 12 parts of isobutyl acrylate, methacrylic acid 3.6 parts of n-butyl ester, 0.6 parts of methacrylic acid, 54 parts of dehydrated castor oil, 10 parts of phthalic anhydride, 14 parts of isophthalic acid, 5 parts of trimethylol propane, 26 parts of dimethylol propionic acid, 2 parts of antioxidant, 26 parts of cosolvent, 12 parts of neutralizer, 16 parts of p-xylene, 16 parts of water;

[0026] The cosolvent is composed of propylene glycol methyl ether acetate, isopropanol, isobutanol, n-butanol and sec-butanol. The neutralizing agent is composed of triethylamine, dimethylethanolamine, ammonia water and 2-amino-2-methyl-1-propanol. The initiator is benzoyl peroxide, azobisisobutyronitrile, 2,2-azobis(methylbutyronitrile) and 2,2-azo(2,4-dimethylvaleronitrile) One or more than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com