A kind of modified thermosetting resin and preparation method thereof

A thermosetting and resin technology, applied in the field of modified thermosetting resin and its preparation, can solve the problems of not meeting the modification requirements of heat-resistant thermosetting resin, reducing heat resistance, low thermal performance, etc., and achieving good compatibility and interaction , the effect of wide source of raw materials and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of epoxy polysiloxane microspheres

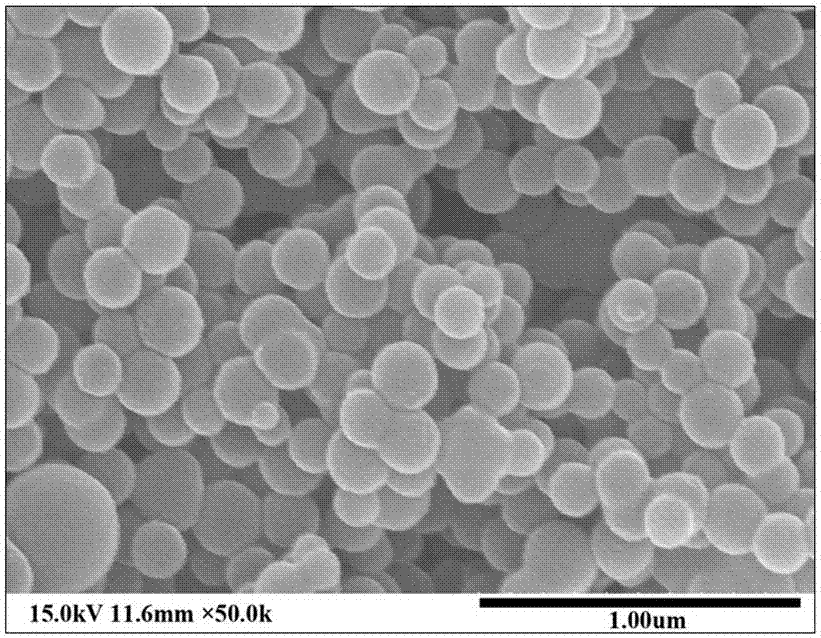

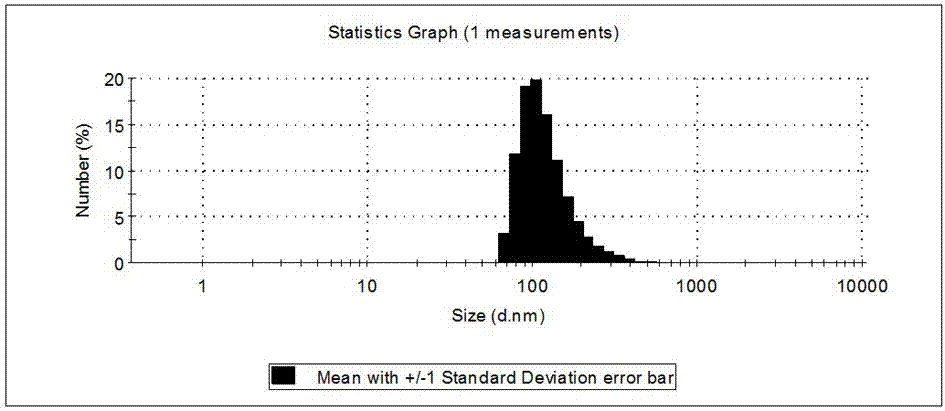

[0037] Stir 0.50g sodium lauryl sulfate, 0.11g nonylphenol polyoxyethylene ether and 100g deionized water at 100r / min for 5min to obtain a clear and transparent mixed solution A; add 12.02g octamethyl Cyclotetrasiloxane and 5.51g methyltrimethoxysilane were stirred at 300r / min for 10min; ultrasonically stirred for 20min to obtain milky white homogeneous solution B; solution B was heated to 80°C; at a stirring speed of 400r / min, the Add 0.61 p-toluenesulfonic acid to the solution and react for 8 hours; cool down to 60°C, add 1.02g of γ-glycidyl etheroxypropyltrimethoxysilane pre-emulsion dropwise at a rate of 2 drops / second, and then react at 60°C for 2 hours ; At 60° C., add 1.03 g of end-capping agent and react for 1 hour; demulsify, filter, and wash with methanol to obtain epoxy polysiloxane microspheres. The scanning electron micrograph and particle size distribution of this epoxy-based polysiloxane microsphere ar...

Embodiment 2

[0046] Preparation of cured product of modified cyanate resin

[0047] Add 1.21g of polysiloxane-coated polyimide core-shell microspheres and 58.79g of 2,2'-bis(4-cyanophenyl)propane provided in step (2) of Example 1 into the beaker, Stir at 180°C for 2.5h to obtain a prepolymer; pour the prepolymer into a mold, vacuum defoam for 30min, and cure according to the process of 180°C / 2h+200°C / 2h+220°C 2h and 240°C / 4h And heat treatment, the modified cyanate resin is obtained. For its thermal weight loss curve, impact strength, loss factor (tan delt)-temperature change curve and storage modulus-temperature change curve, please refer to the attached Figure 7 , 8 , 9 and 10.

Embodiment 3

[0055] (1) Preparation of polysiloxane-coated polyimide core-shell microspheres

[0056] Add 0.51g sodium lauryl sulfate and 0.12g nonylphenol polyoxyethylene ether to 100g deionized water and stir at 100r / min for 5min to obtain a clear and transparent mixed solution A; Cyclotetrasiloxane, 5.51g methyltriethoxysilane, stirred at 300r / min for 15min; ultrasonically stirred for 20min to obtain milky white homogeneous solution B; solution B was heated to 80°C; at a stirring speed of 450r / min , add 0.61g of p-toluenesulfonic acid, stir and react for 8h, cool down to 60°C, add 1.01g of γ-glycidyl etheroxypropyltrimethoxysilane pre-emulsion dropwise at a rate of 2 drops / second, and then react at 60°C for 2h ; At 60° C., add 1.01 g of end-capping agent and react for 1 h; break the emulsion, filter, and wash with methanol to obtain epoxy polysiloxane microspheres.

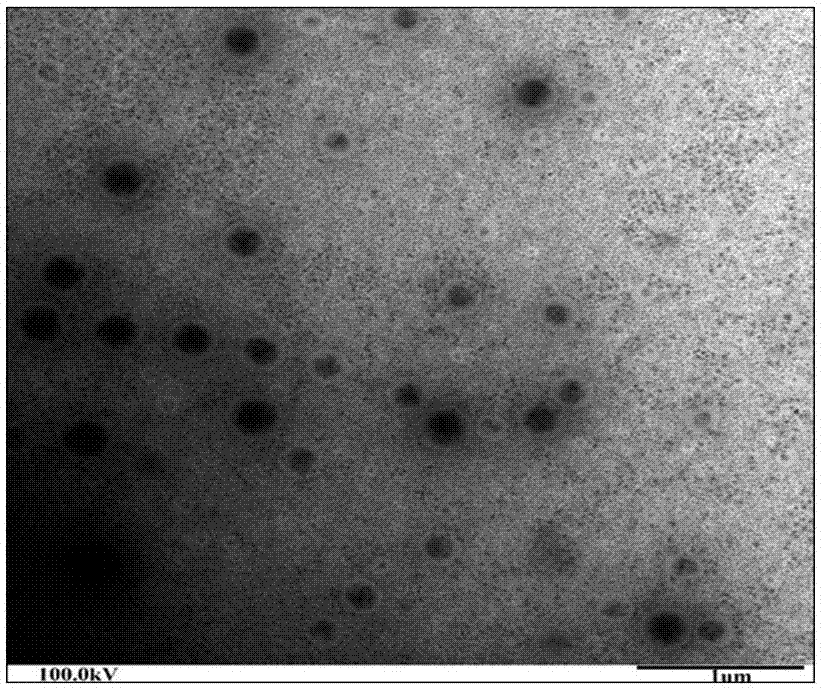

[0057] Under argon protection, 8 g of epoxy polysiloxane microspheres were added to a clear and transparent solution con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com