Soybean-based protein adhesive and preparation method thereof

An adhesive and protein glue technology, applied in the field of fine chemicals, can solve the problems of poor water-resistant bonding strength and high viscosity, and achieve the effects of improving bonding strength, simple production process, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

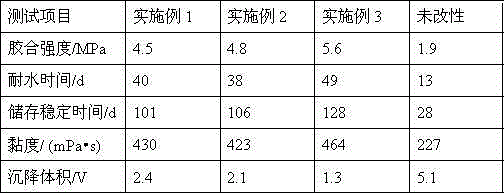

Examples

Embodiment 1

[0018] Soybean-based protein adhesive, the components and the parts by mass of each component are as follows: 20 parts of soybean powder, 5 parts of polyol polyethylene glycol, 5 parts of sodium lauryl sulfate, and 10 parts of trimethylolpropane triester , 2 parts of urea, 3 parts of carboxyethyl cellulose, 1 part of dioctyl disulfide, 1 part of isocyanate, 1 part of sodium hydroxide, 1 part of dibenzoyl peroxide, 1 part of maleic anhydride, 1 part of diisopropylamine nitrite, 1 part of stabilizer dimethylaniline, 40 parts of water.

[0019] The preparation method comprises the steps of:

[0020] 1) Mix soybean powder with water, then add sodium hydroxide, stir evenly, add sodium lauryl sulfate, trimethylolpropane triester, urea, carboxyethyl cellulose, dioctyl dibutyrate sulfide Carry out graft modification with isocyanate, heat up to 80°C, and stir at 170rpm for 4h;

[0021] 2) Add the remaining components to the solution in step 1), and stir at a speed of 130 rpm to obtai...

Embodiment 2

[0023] Soybean-based protein adhesive, the components and the parts by mass of each component are as follows: 30 parts of soybean powder, 10 parts of polyol polyethylene glycol, 8 parts of sodium lauryl sulfate, and 15 parts of trimethylolpropane triester , 6 parts of urea, 5 parts of carboxyethyl cellulose, 3 parts of dioctyl disulfide, 2 parts of isocyanate, 2 parts of sodium hydroxide, 3 parts of dibenzoyl peroxide, 3 parts of maleic anhydride, 2 parts of diisopropylamine nitrite, 2 parts of stabilizer dimethylaniline, 60 parts of water.

[0024] The preparation method comprises the steps of:

[0025] 1) Mix soybean powder with water, then add sodium hydroxide, stir evenly, add sodium lauryl sulfate, trimethylolpropane triester, urea, carboxyethyl cellulose, dioctyl dibutyrate sulfide Carry out graft modification with isocyanate, heat up to 80°C, and stir at 170rpm for 4h;

[0026] 2) Add the remaining components to the solution in step 1), and stir at a speed of 130 rpm ...

Embodiment 3

[0028] Soybean-based protein adhesive, the components and the parts by mass of each component are as follows: 25 parts of soybean powder, 8 parts of polyol glycerin, 6.5 parts of sodium lauryl sulfate, 12.5 parts of trimethylolpropane triester, 4 parts of urea, 4 parts of carboxyethyl cellulose, 2 parts of dioctyl sulfide, 1.5 parts of isocyanate, 1.5 parts of sodium hydroxide, 2 parts of dibenzoyl peroxide, 2 parts of maleic anhydride, 1.5 parts of diisopropylamine nitrate, 1.5 parts of stabilizer ethylenediamine, 50 parts of water.

[0029] The preparation method comprises the steps of:

[0030] 1) Mix soybean powder with water, then add sodium hydroxide, stir evenly, add sodium lauryl sulfate, trimethylolpropane triester, urea, carboxyethyl cellulose, dioctyl dibutyrate sulfide Carry out graft modification with isocyanate, heat up to 80°C, and stir at 170rpm for 4h;

[0031] 2) Add the remaining components to the solution in step 1), and stir at a speed of 130 rpm to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com