Solid-state continuous fermentation method of Bacillus subtilis

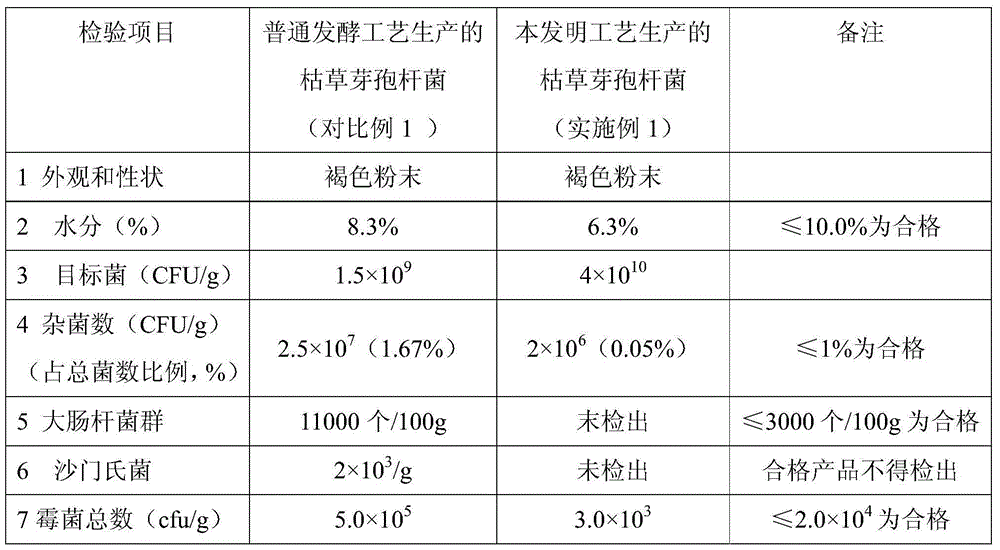

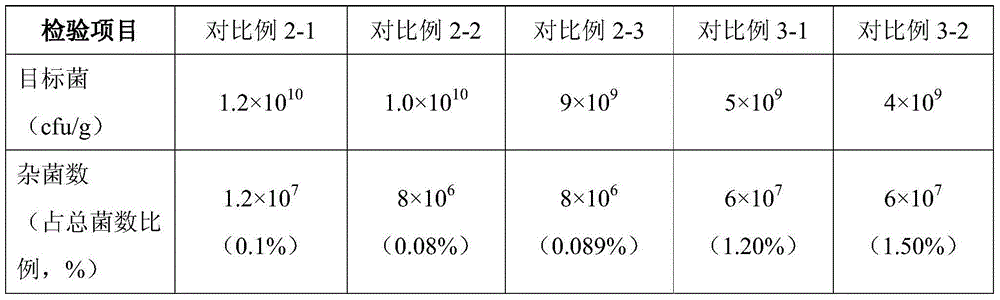

A Bacillus subtilis, fermentation method technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems that Escherichia coli and Salmonella are easy to exceed the standard, affect the application of Bacillus subtilis, and are not suitable for large-scale production. , to achieve the effect of reducing the chance of bacterial contamination, reducing the cost of manual transportation, and achieving uniform fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

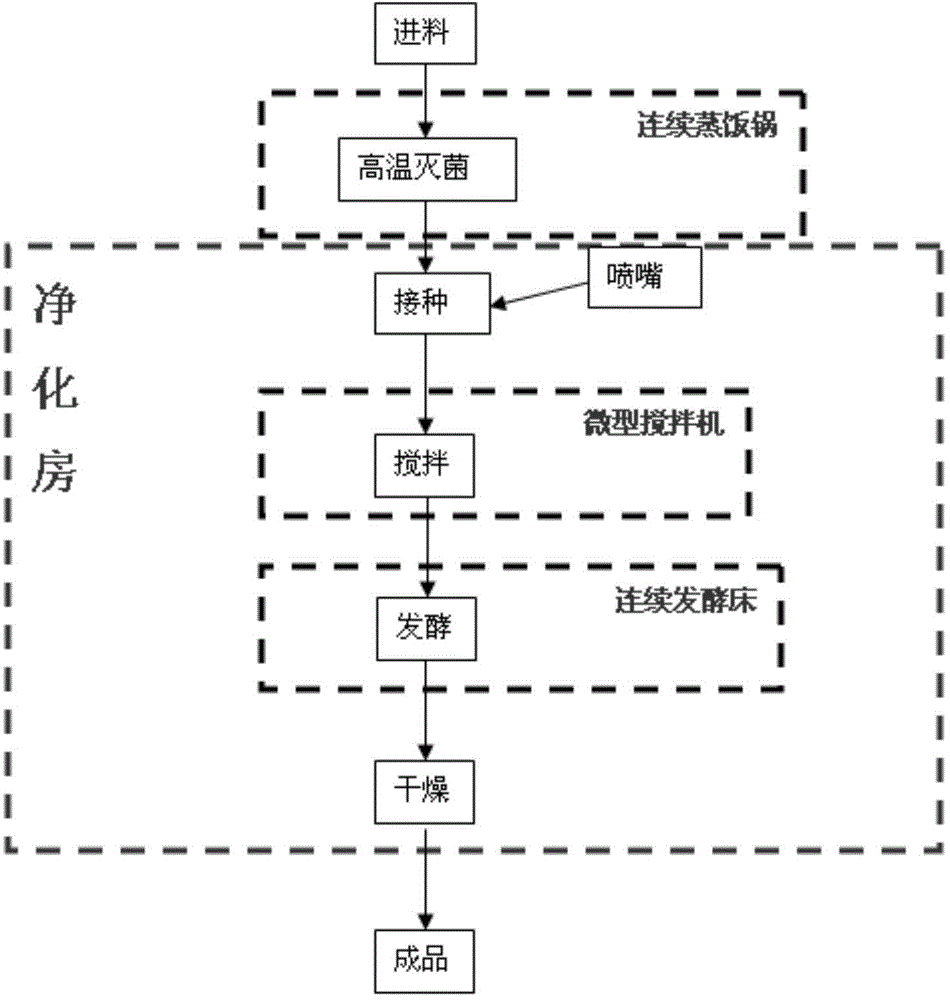

[0037] Embodiment 1, a kind of solid-state continuous fermentation method of Bacillus subtilis, carries out following steps successively:

[0038] 1) Feed the solid-state fermentation material through the feeding bin, and carry out high-temperature sterilization (sterilization at 120-121°C for 20 minutes) in continuous sterilization equipment (such as a continuous rice cooker);

[0039] The solid fermented material is obtained by mixing soybean meal, bran, fish meal and calcium carbonate according to the weight ratio of 80%:15%:4%:1%.

[0040] 2), in a closed clean room, insert activated Bacillus subtilis into the sterilized solid-state fermentation material obtained in step 1), and fully stir evenly;

[0041] The inoculation amount is: 8g of activated Bacillus subtilis is used for every 100g of solid-state fermentation material;

[0042] Bacillus subtilis is selected as the Bacillus subtilis numbered CGMCC9383 of the General Microbiology Center of China Microbiological Cultu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com