Method for cultivating microalgae to generate hydrogen

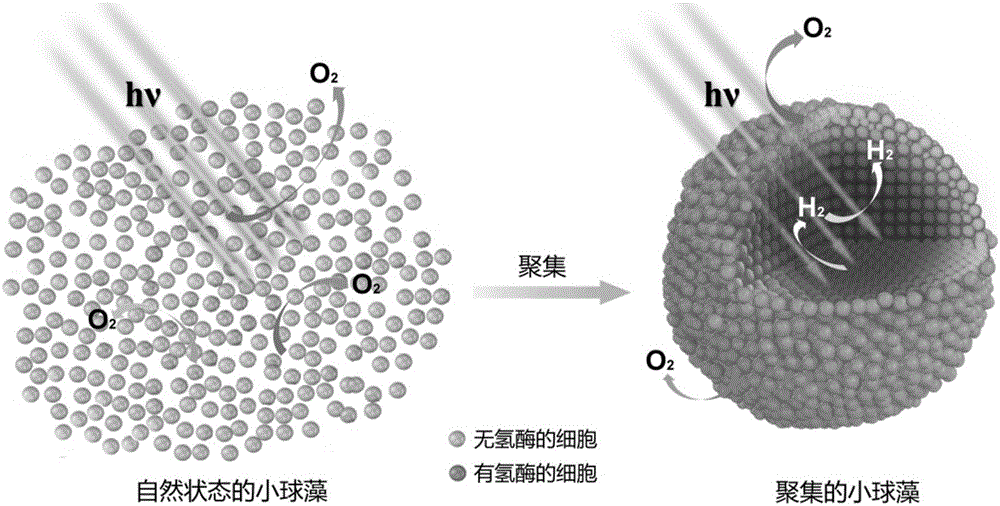

A technology for producing hydrogen and microalgae, applied in biological engineering and fields, can solve the problems of low efficiency and short duration of hydrogen production by microalgae, and achieve the effect of simple preparation process and improved hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

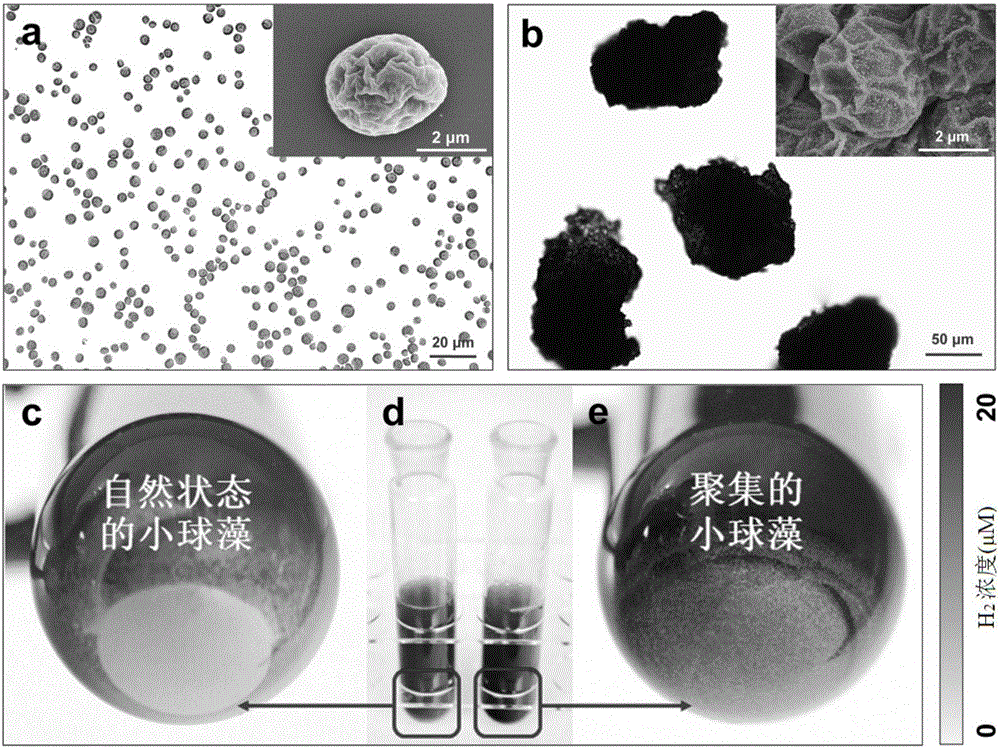

[0036] The commercialized Chlorella pyrenoidosa was selected as the experimental object.

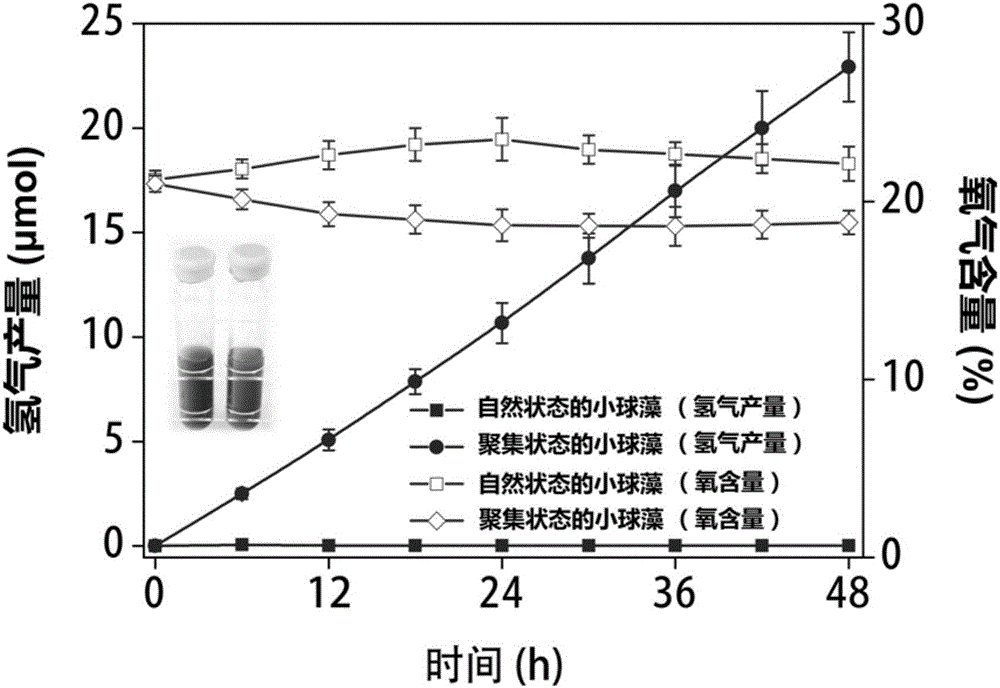

[0037] Add polydimethyldiallyl ammonium chloride (PDADMAC) in an amount of 1 g / L to the logarithmic growth phase Chlorella cell solution (cell density 1.2 × 10 8 cells / mL) for surface modification to positively charge the surface. Then centrifuge and wash, then centrifuge again, and finally mix the 5mM silicic acid solution with the centrifuged chlorella cells quickly, blow them away, put them in a beaker and stir for 30min. Collect Chlorella cells, wash and resuspend with TAP medium, then aliquot to a volume of 60 cm 3 In sealed tubes, 30mL of algae liquid per tube. Taking the chlorella in natural state as the control, they were divided into two groups. at 100μE·m -2 ·s -1 Exposure to light for 48 hours.

[0038] Experiment 1. The natural state of Chlorella pyrenoidosa and aggregated Chlorella pyrenoidosa were observed under an optical microscope and a scanning electron microscope...

Embodiment 2

[0047] The selected algal species is consistent with that in Example 1, which is Chlorella pyrenoidosa.

[0048] Add polydimethyldiallyl ammonium chloride in the amount of 0.5g / L to the Chlorella cell solution in the logarithmic growth phase (cell density 1.2×10 8 cells / mL) for surface modification to positively charge the surface. Then centrifuge and wash, then centrifuge again, and finally mix the 5mM silicic acid solution with the centrifuged chlorella cells quickly, blow them away, put them in a beaker and stir for 30min. Collect Chlorella cells, wash and resuspend with TAP medium, then aliquot to a volume of 60 cm 3 In sealed tubes, 30mL of algae liquid per tube. at 100μE·m -2 ·s -1 Irradiate under light for 48 hours, and measure the accumulated amount of hydrogen in the headspace of the sealed tube.

Embodiment 3

[0050] The selected algal species is consistent with that in Example 1, which is Chlorella pyrenoidosa.

[0051] Add polydimethyldiallyl ammonium chloride to the Chlorella cell solution in the logarithmic growth phase in an amount of 1.5g / L (cell density 1.2×10 8 cells / mL) for surface modification to positively charge the surface. Then centrifuge and wash, then centrifuge again, and finally mix the 5mM silicic acid solution with the centrifuged chlorella cells quickly, blow them away, put them in a beaker and stir for 30min. Collect Chlorella cells, wash and resuspend with TAP medium, then aliquot to a volume of 60 cm 3 In sealed tubes, 30mL of algae liquid per tube. at 100μE·m -2 ·s -1 Irradiate under light for 48 hours, and measure the accumulated amount of hydrogen in the headspace of the sealed tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com