Degradable composite nanofiber and its preparation method and use

A technology of composite nanofibers and electrospinning, which is applied in the field of tissue engineering in internal medicine to achieve the effects of uniform distribution, large specific surface area, and simple and controllable preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

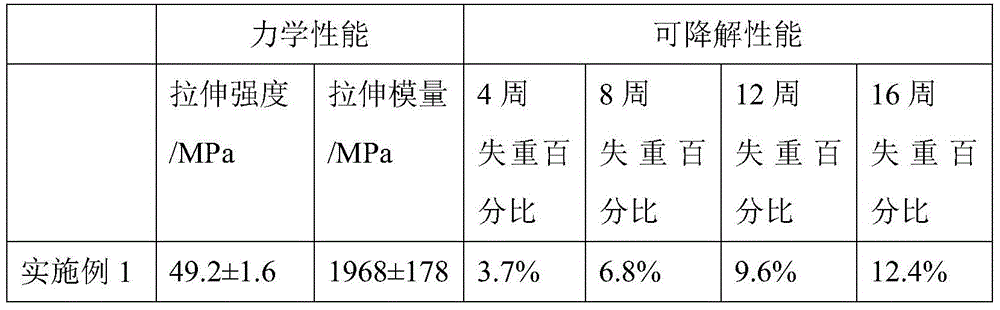

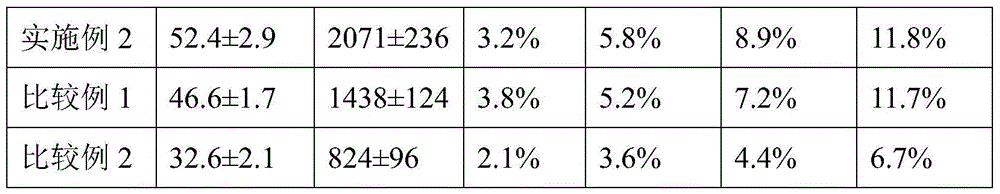

Examples

Embodiment 1

[0029] First, dry pentaerythritol PTOL in a vacuum oven at 40°C overnight; prepare stannous octoate as a dilute solution in toluene, and recrystallize LLA with ethyl acetate, and dry it in vacuum for later use. Under nitrogen protection, the monomer LLA and the initiator PTOL were added to the reaction vessel, followed by the catalyst stannous octoate; wherein the monomer concentration was 0.3mg / L, and the molar ratio of the monomer LLA to PTOL was 40:1 , the molar ratio of stannous octoate to PTOL is 1:12. Then add toluene dried under reflux with sodium as a solvent, and react at 100°C for 42 hours to obtain star-shaped polylactic acid. The obtained star-shaped polylactic acid was dissolved in dichloromethane, precipitated with anhydrous methanol, and dried in a vacuum drying oven for 24 hours after the solvent evaporated.

[0030] The obtained product is characterized by HNMR, and there are three proton peaks, which are 5.23ppm, 3.79ppm and 1.60ppm respectively; wherein, 5....

Embodiment 2

[0034] First, dry pentaerythritol PTOL in a vacuum oven at 40°C overnight; prepare stannous octoate as a dilute solution in toluene, and recrystallize LLA with ethyl acetate, and dry it in vacuum for later use. Under the protection of nitrogen, the monomer LLA and the initiator PTOL were added to the reaction vessel, and then the catalyst stannous octoate was added; wherein, the monomer concentration was 0.5 mg / L, and the molar ratio of the monomer LLA to PTOL was 100:1 , the molar ratio of stannous octoate to PTOL is 1:14. Then add toluene dried under reflux with sodium as a solvent, and react at 120°C for 54 hours to obtain star-shaped polylactic acid. The obtained star-shaped polylactic acid was dissolved in dichloromethane, precipitated with anhydrous methanol, and dried in a vacuum drying oven for 24 hours after the solvent evaporated.

[0035] Use gel permeation chromatography GPC to measure the number average molecular weight Mn=4.2*10 of gained star polylactic acid 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com