Nitrogen-doped carbon quantum dot with high fluorescence quantum yield and preparation method and application of nitrogen-doped carbon quantum dot

A fluorescence quantum yield, carbon quantum dot technology, applied in fluorescence/phosphorescence, chemical instruments and methods, preparations for in vivo experiments, etc. Meet the needs of industrial applications, high fluorescence quantum efficiency, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

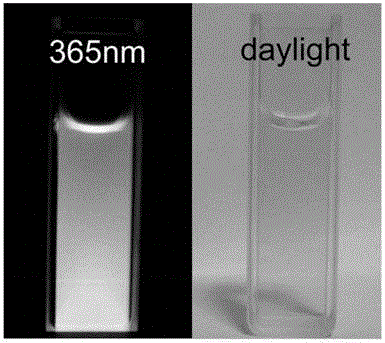

[0033] Add 3 g of urea and 1 mL of HOOC-PEG-COOH (Mw 600) into a three-necked flask filled with 25 mL of glycerol or diethylene glycol, and put it in a water bath at 80°C until the urea is completely dissolved. Under the protection of inert gas, heat to 120 °C and keep it for 1 h to remove water, then raise the temperature to 220 °C and keep it for 4 h, then stop heating. The resulting mixture was dialyzed for two days using a dialysis bag with a molecular weight cut-off of 1K, and then the product was concentrated by a rotary evaporator, and the obtained viscous brown liquid, namely fluorescent carbon dots, was freeze-dried. According to transmission electron microscopy analysis, the size of carbon dots is 2-4 nm, and the nitrogen content is 9wt% as measured by elemental analysis. It shows bright blue fluorescence under excitation at 365 nm wavelength.

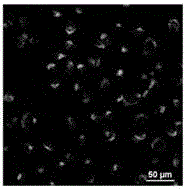

[0034] Seed 1*10 in each well of 96-well plate 4 HeLa cells were cultured for 24 h. Add different concentrations (6, 12, ...

Embodiment 2

[0037] Add 0.1 g of urea and 0.1 mL of HOOC-PEG-COOH (Mw 600) into a three-necked flask filled with 5 mL of glycerol or diethylene glycol, and bathe in 80°C water until the urea is completely dissolved. Under the protection of inert gas, heat to 120 °C and keep it for 1 h to remove water, then raise the temperature to 200 °C and keep it for 8 h, then stop heating. The resulting mixture was dialyzed for two days using a dialysis bag with a molecular weight cut-off of 1K, and then the product was concentrated by a rotary evaporator, and the obtained viscous brown liquid, namely fluorescent carbon dots, was freeze-dried. According to transmission electron microscopy analysis, the size of carbon dots is 2-4 nm, and the nitrogen content is 6wt% as measured by elemental analysis. It shows bright blue fluorescence under excitation at 365 nm wavelength.

[0038] Seed 1*10 in each well of 96-well plate 4 HeLa cells were cultured for 24 h. Add different concentrations (6, 12, 25, 50, ...

Embodiment 3

[0041] Add 5 g of urea and 1 mL of HOOC-PEG-COOH (Mw 600) into a three-necked flask filled with 25 mL of glycerol or diethylene glycol, and put it in a water bath at 80°C until the urea is completely dissolved. Under the protection of inert gas, heat to 120°C and keep it for 1 hour to remove water, then raise the temperature to 240°C and keep it for 1 hour, then stop heating. The resulting mixture was dialyzed for two days using a dialysis bag with a molecular weight cut-off of 1K, and then the product was concentrated by a rotary evaporator, and the obtained viscous brown liquid, namely fluorescent carbon dots, was freeze-dried. According to transmission electron microscopy analysis, the size of carbon dots is 2-4 nm, and the nitrogen content is 10wt% as measured by elemental analysis. It shows bright blue fluorescence under excitation at 365 nm wavelength.

[0042] Seed 1*10 in each well of 96-well plate 4 HeLa cells were cultured for 24 h. Add different concentrations (6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com