Plant fiber based solid amine adsorption material, preparation method and application thereof

A technology of plant fibers and adsorption materials, which is applied in the field of plant fiber-based solid amine adsorption materials and its preparation, can solve the problems that the adsorption capacity of materials cannot be further improved, and the adsorption sites of solid amine fibers are limited, so as to achieve the improvement of adsorption capacity , good thermal and chemical stability, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

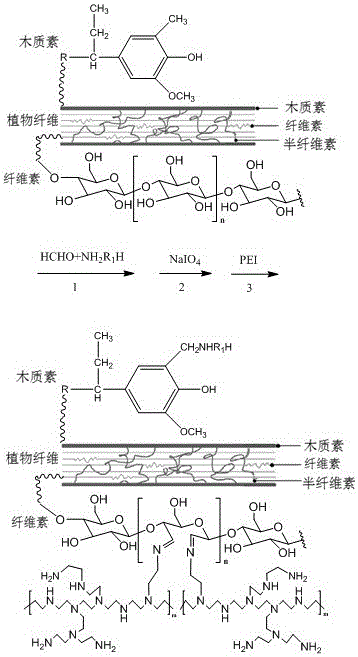

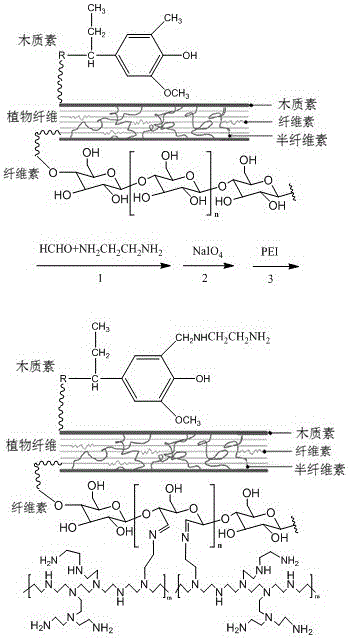

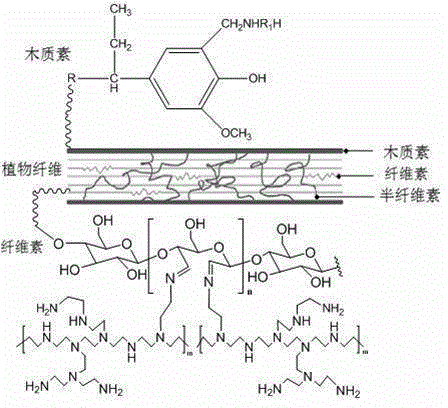

Method used

Image

Examples

Embodiment 1

[0044] 1. Preparation

[0045] (1) According to the mass ratio of lignin: formaldehyde: ethylenediamine in bagasse, which is 1:1.5:5, add it into 100mL solvent and mix evenly, and react for 4h at 25°C under ultrasonic vibration with power of 100, After the reaction is completed, rinse with water and ethanol repeatedly, filter with suction, and dry at 45° C. to obtain bagasse-based Mannich base lignin-cellulose.

[0046] (2) The bagasse-based Mannich base lignin-cellulose will be placed in 5wt% NaIO 4 In an aqueous solution, in an ultrasonic vibration with a power of 100, the oxidation reaction was carried out at 25°C for 3 hours. After the reaction was completed, it was repeatedly washed with water and ethanol, filtered with suction, and dried at 45°C to obtain bagasse-based Mannich base lignin-bis Aldehyde fibers;

[0047] (3) Mix bagasse-based Mannich base lignin-dialdehyde fibers with 5wt% polyethyleneimine aqueous solution with a molecular weight of 1800g / mol, amination ...

Embodiment 2

[0052] 1. Preparation

[0053] (1) According to the mass ratio of lignin in sisal: formaldehyde: diethylenetriamine is 1:3:9, add 100mL of water and mix evenly, and react at 40°C for 10h in an ultrasonic vibration with a power of 200W. After the reaction is completed, it is repeatedly washed with water and ethanol, filtered with suction, and dried at 45° C. to obtain sisal-based Mannich base lignin-cellulose.

[0054] (2) Put sisal-based Mannich base lignin-cellulose in 15wt% NaIO 4 In an aqueous solution, in an ultrasonic vibration with a power of 300W, the oxidation reaction was carried out at 50°C for 6 hours. After the reaction was completed, it was repeatedly rinsed with water and ethanol, filtered with suction, and dried at 45°C to obtain sisal-based Mannich base lignin-bis Aldehyde fibers;

[0055] (3) Mix sisal-based Mannich base lignin-dialdehyde fibers with 10wt% polyethyleneimine aqueous solution with a molecular weight of 10000g / mol, amination reaction at 50°C fo...

Embodiment 3

[0060] 1. Preparation

[0061] (1) According to the mass ratio of lignin: formaldehyde: triethylenetetramine in corncobs of 1:3:9, add it into 100mL of methanol and mix evenly, and react at 60°C for 48h in an ultrasonic vibration with a power of 400W. After the reaction is completed, rinse with water and ethanol repeatedly, filter with suction, and dry at 45° C. to obtain bagasse-based Mannich base lignin-cellulose.

[0062] (2) The corncob-based Mannich base lignin-cellulose will be placed in 20wt% NaIO 4 In an aqueous solution, in an ultrasonic vibration with a power of 400W, the oxidation reaction was carried out at 70°C for 8 hours. After the reaction was completed, it was repeatedly rinsed with water and ethanol, filtered with suction, and dried at 45°C to obtain bagasse-based Mannich base lignin-bis Aldehyde fibers;

[0063] (3) Mix the corncob-based Mannich base lignin-dialdehyde fiber with 20wt% polyethyleneimine aqueous solution with a molecular weight of 70,000g / mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com