Method for preparing sodium-potassium bismuth titanate nano-microspheres by micro-emulsion method

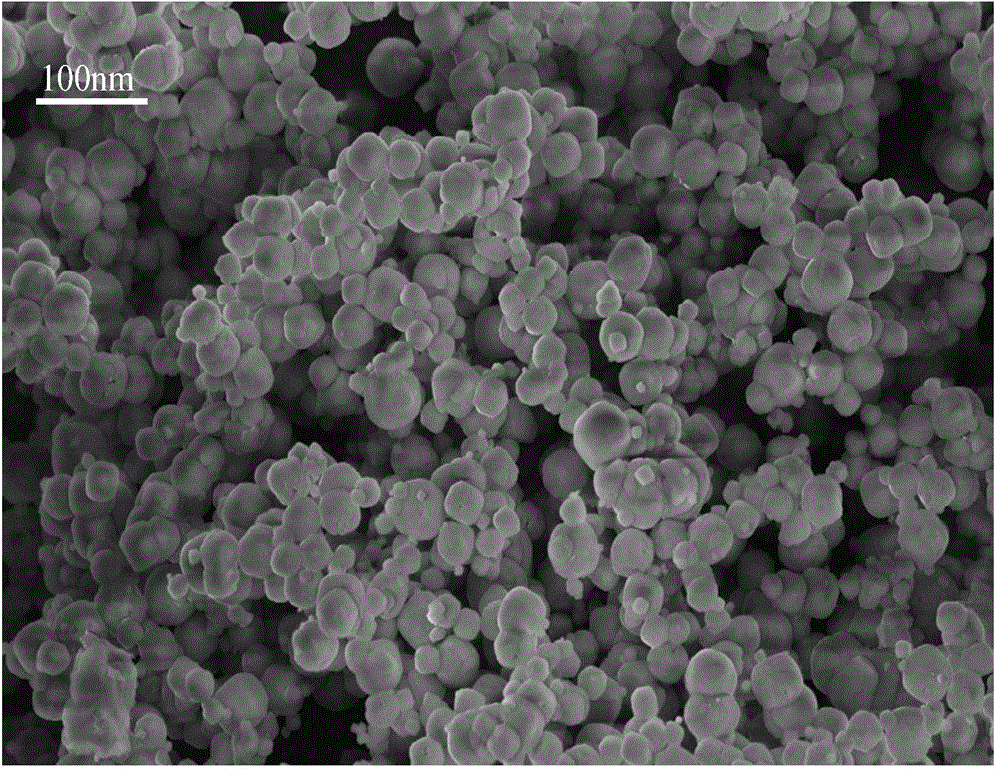

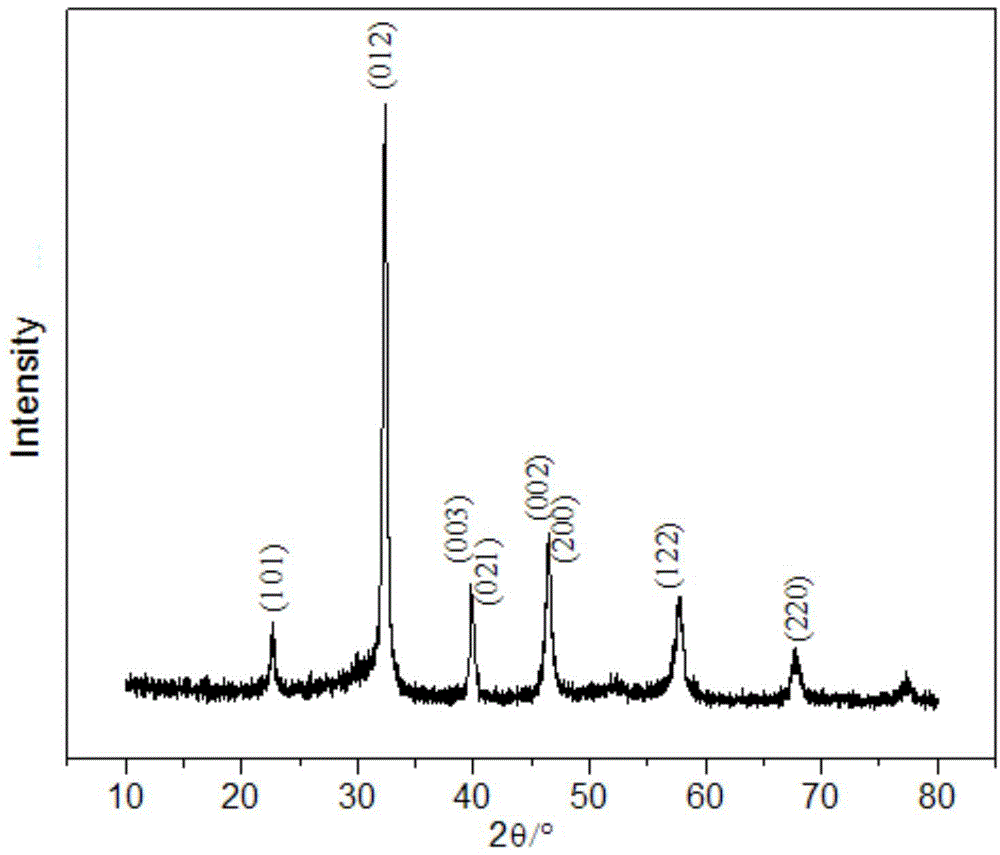

A technology for preparing bismuth sodium potassium titanate and nano-microspheres, which is applied in the field of preparing bismuth sodium-potassium titanate nano-microspheres by microemulsion method, can solve the problem of affecting the electrical properties of piezoelectric ceramic materials, the uneven particle size of synthetic powders, the pressure Solve the problems of low purity of electroceramic materials, and achieve the effect of huge surface free energy, strong repeatability and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment includes the following steps:

[0028] Step 1, weigh sodium nitrate, potassium nitrate, bismuth nitrate and tetrabutyl titanate according to the molar ratio Na:K:Bi:Ti=0.4:0.1:0.5:1, then dissolve the weighed sodium nitrate and potassium nitrate in In deionized water, mixture A is obtained, and the bismuth nitrate taken by weighing is added to deionized water and mixed uniformly to obtain mixture B; the metal ion molar concentration in the mixture A is 0.25mol / L, and the molar concentration of bismuth nitrate in the mixture B is The concentration is 0.25mol / L;

[0029] Step 2. Mix cyclohexane and tetrabutyl titanate weighed in step 1 uniformly at a volume ratio of 7:1 to obtain a mixture C;

[0030] Step 3, surfactant and cosurfactant are mixed uniformly by volume ratio 4:1, obtain mixing aid; Described surfactant is made of cetyltrimethylammonium bromide and sorbitan monooleic acid Ester polyoxyethylene ether is mixed in molar ratio 2:1, and described...

Embodiment 2

[0036] This embodiment includes the following steps:

[0037] Step 1, weigh sodium nitrate, potassium nitrate, bismuth nitrate and tetrabutyl titanate according to the molar ratio Na:K:Bi:Ti=0.4:0.1:0.5:1, then dissolve the weighed sodium nitrate and potassium nitrate in In deionized water, mixture A is obtained, and the bismuth nitrate taken by weighing is added to deionized water and mixed uniformly to obtain mixture B; the metal ion molar concentration in the mixture A is 0.1mol / L, and the molar concentration of bismuth nitrate in the mixture B is The concentration is 0.5mol / L;

[0038] Step 2. Mix cyclohexane and tetrabutyl titanate weighed in step 1 uniformly at a volume ratio of 6:1 to obtain a mixture C;

[0039] Step 3, surfactant and cosurfactant are mixed uniformly by volume ratio 3:1, obtain mixing aid; Described surfactant is made of cetyltrimethylammonium bromide and sorbitan monooleic acid Ester polyoxyethylene ether is mixed at a molar ratio of 1:1, and the co...

Embodiment 3

[0045] This embodiment includes the following steps:

[0046] Step 1, weigh sodium nitrate, potassium nitrate, bismuth nitrate and tetrabutyl titanate according to the molar ratio Na:K:Bi:Ti=0.4:0.1:0.5:1, then dissolve the weighed sodium nitrate and potassium nitrate in In deionized water, mixture A is obtained, and the bismuth nitrate taken by weighing is added to deionized water and mixed uniformly to obtain mixture B; the metal ion molar concentration in the mixture A is 0.5mol / L, and the molar concentration of bismuth nitrate in the mixture B is The concentration is 0.1mol / L;

[0047] Step 2. Mix cyclohexane and tetrabutyl titanate weighed in step 1 uniformly at a volume ratio of 8:1 to obtain a mixture C;

[0048] Step 3, surfactant and cosurfactant are mixed uniformly by volume ratio 5:1, obtain mixing aid; Described surfactant is made of cetyltrimethylammonium bromide and sorbitan monooleic acid Ester polyoxyethylene ether is mixed with molar ratio 1.5:1, and describ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com