Method for preparing photocatalyst ceramic by means of potassium tetratitanate whiskers

A technology of photocatalytic ceramics and potassium tetratitanate, applied in ceramic products, applications, household appliances, etc., can solve the problems of reduced photocatalytic efficiency, difficult application, weak film strength and impact resistance, and achieve low energy cost, Less secondary pollution, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

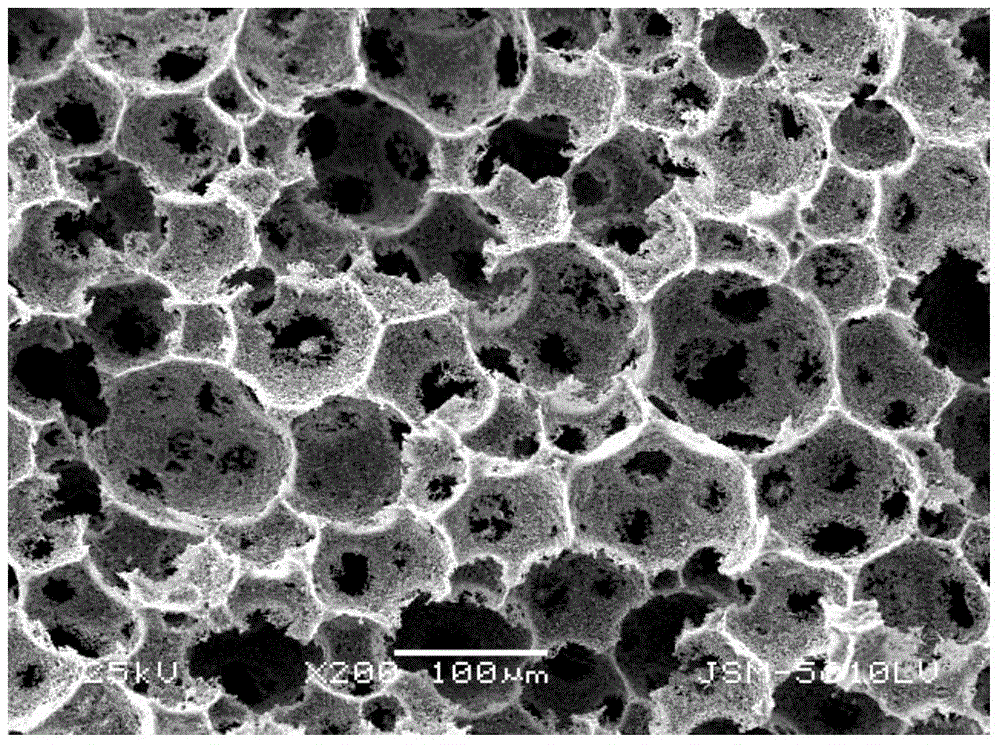

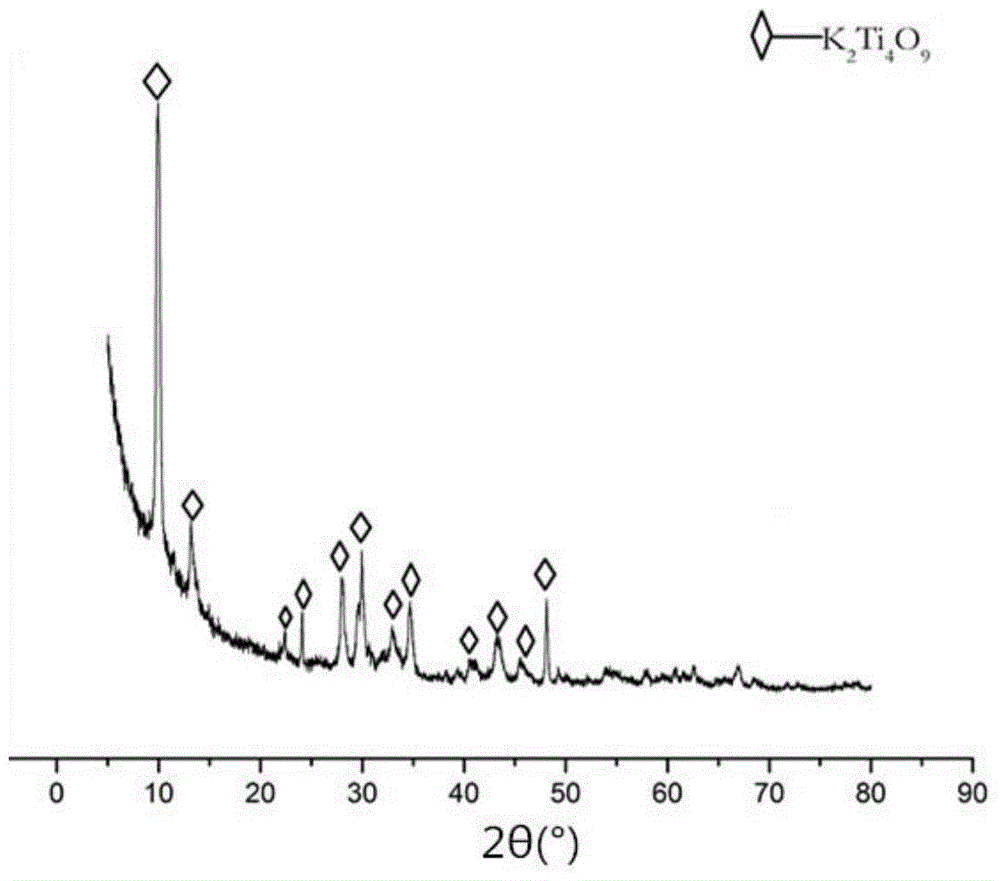

[0027] Weigh 27 g of potassium tetratitanate whiskers, and after ball milling in a ball mill for 15 hours, the whisker aspect ratio is measured to be about 7. Take a certain mass of potassium tetratitanate whiskers and add deionized water to prepare a mixture with a solid content of 30 wt%. Slurry, then add silane coupling agent (silane coupling agent and potassium tetratitanate whisker are 3:1000 by mass ratio), stir on magnetic stirrer for 5h, use vacuum suction filter and dry in oven Dry it for later use; use the modified whisker and add deionized water to prepare a ceramic slurry with a solid content of 44wt%, and add 0.8g of low-temperature glass powder as a binder, and then use 1mol / L NaOH solution to adjust pH to 11, stir on a magnetic stirrer at high speed for 3 hours to fully disperse potassium tetratitanate whiskers in deionized water, add 0.6g ethyl gallate as whisker surface modifier, stir on a magnetic stirrer at low speed 1h. Then use a frequency conversion mixe...

Embodiment 2

[0030] Weigh 30 g of potassium tetratitanate whiskers, and after ball milling in a ball mill for 15 hours, the whisker length-to-diameter ratio is measured to be about 7. Take a certain mass of potassium tetratitanate whiskers and add deionized water to prepare a mixture with a solid content of 30 wt%. Slurry, then add silane coupling agent (silane coupling agent and potassium tetratitanate whisker are 3:1000 by mass ratio), stir on magnetic stirrer for 5h, use vacuum suction filter and dry in oven Dry and set aside; then use the modified whiskers, add deionized water to prepare a ceramic slurry with a solid content of 47wt%, and add 1g of low-temperature glass powder as a binder, and then adjust the pH with 1mol / L NaOH solution To 11, stir at high speed on a magnetic stirrer for 5 hours to fully disperse potassium tetratitanate whiskers in deionized water, add 0.54 g of propyl gallate as a whisker surface modifier, and stir at low speed on a magnetic stirrer for 1 hour . The...

Embodiment 3

[0033]Weigh 24 g of potassium tetratitanate whiskers, and after ball milling in a ball mill for 15 hours, the whisker aspect ratio is measured to be about 7. Take a certain mass of potassium tetratitanate whiskers and add deionized water to prepare a mixture with a solid content of 30 wt%. Slurry, then add silane coupling agent (silane coupling agent and potassium tetratitanate whisker are 3:1000 by mass ratio), stir on magnetic stirrer for 5h, use vacuum suction filter and dry in oven Dry and set aside; then use the modified whiskers, add deionized water to prepare a ceramic slurry with a solid content of 42wt%, and add 0.6g of low-temperature glass powder as a binder, and then use 1mol / L NaOH solution to adjust pH to 10, stir at high speed on a magnetic stirrer for 4 hours to fully disperse potassium tetratitanate whiskers in deionized water, add 0.54g ethyl gallate as whisker surface modifier, stir at low speed on a magnetic stirrer 1h. Then use a frequency conversion mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com