Sulfur-free and efficient cleaning method for sugar juice

A high-efficiency technology for sugar juice, applied in the purification of sugar juice, the use of physical methods to purify, and sucrose production. It can solve the problems of increasing sugar loss and production energy consumption, high material quality requirements, and more sucrose conversion. The effect of high chemical depth development value, less sugar loss and simple treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

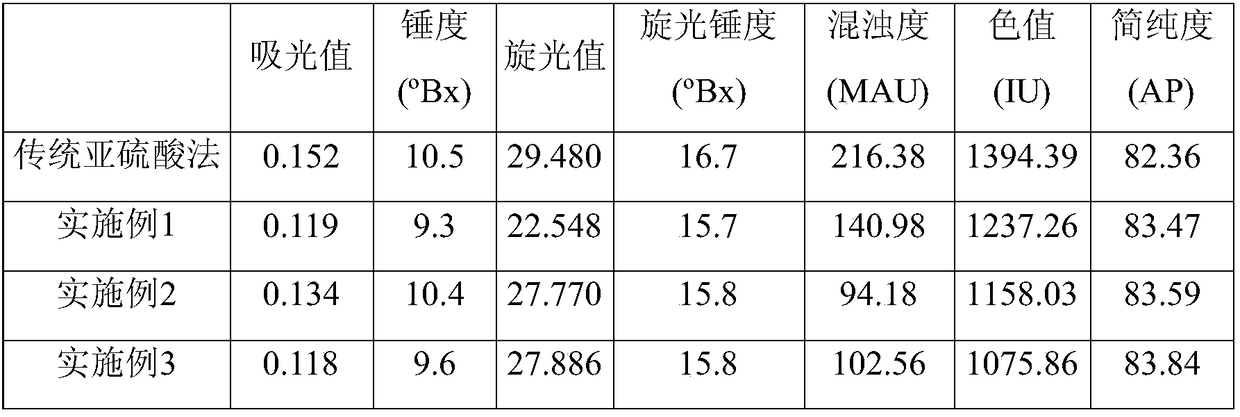

Embodiment 1

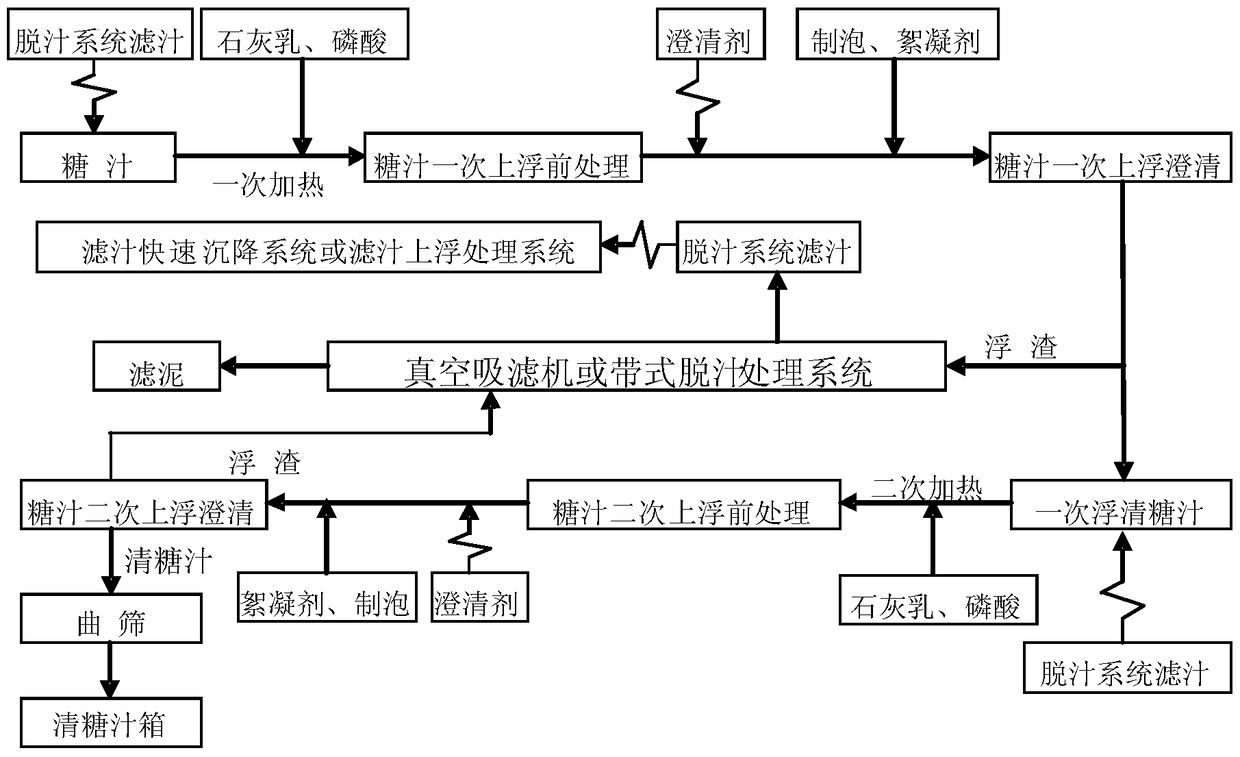

[0035]A sulfur-free and efficient cleaning method for sugar juice, the specific steps are as follows:

[0036] (1) Pre-treatment of the sugar juice once floating: add lime milk and phosphoric acid to the sugar juice, adjust the total phosphoric acid value in the sugar juice to 200ppm, control the pH value of the sugar juice at 7.5, control the primary heating temperature at 60°C, and then enter the bubble making process - Flocculation reactor, add flocculant 4ppm after foaming sugar juice, fully react;

[0037] (2) One-time flotation clarification of sugar juice: the sugar juice treated before the first flotation flows into the first-time flotation clarifier for solid-liquid separation, and the scum on the upper layer of the clarifier is collected into the scum storage tank through the scum removal system, and the sugar juice is cleared once It is discharged through the clear juice discharge pipe in the lower layer of the clarifier and collected into the primary floating clear...

Embodiment 2

[0042] A sulfur-free and efficient cleaning method for sugar juice, the specific steps are as follows:

[0043] (1) Pre-treatment of the sugar juice once floating: add lime milk and phosphoric acid to the sugar juice, adjust the total phosphoric acid value in the sugar juice to 300ppm, control the pH value of the sugar juice at 8.0, control the primary heating temperature at 65°C, and then add 100ppm of composite clarifying agent (chitosan quaternary ammonium salt and polyaluminum chloride with a mass ratio of 2:1) enters the bubble-flocculation reactor, and adds 4ppm of flocculant after the sugar juice is bubbled to fully react;

[0044] (2) One-time flotation clarification of sugar juice: the sugar juice treated before the first flotation flows into the first-time flotation clarifier for solid-liquid separation, and the scum on the upper layer of the clarifier is collected into the scum storage tank through the scum removal system, and the sugar juice is cleared once It is d...

Embodiment 3

[0049] A sulfur-free and efficient cleaning method for sugar juice, the specific steps are as follows:

[0050] (1) Pre-treatment of the sugar juice once floating: add lime milk and phosphoric acid to the sugar juice, adjust the total phosphoric acid value in the sugar juice at 250ppm, control the pH value of the sugar juice at 8.5, control the primary heating temperature at 70°C, and then add 150ppm of composite clarifying agent (chitosan quaternary ammonium salt and polyaluminum chloride with a mass ratio of 2:1) enters the bubble-flocculation reactor, and adds 4ppm of flocculant after the sugar juice is bubbled to fully react;

[0051] (2) One-time flotation clarification of sugar juice: the sugar juice treated before the first flotation flows into the first-time flotation clarifier for solid-liquid separation, and the scum on the upper layer of the clarifier is collected into the scum storage tank through the scum removal system, and the sugar juice is cleared once It is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com