A method for recovering valuable metals in a multi-metal alloy containing nickel/cobalt

A valuable metal and multi-metal technology, applied in the field of metallurgy and chemical industry, can solve the problems of failure to effectively improve the leaching performance of alloys, unsatisfactory recovery rate of valuable metals, and poor economic benefits of the process, so as to achieve significant environmental protection advantages and furnace use efficiency High, good leaching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

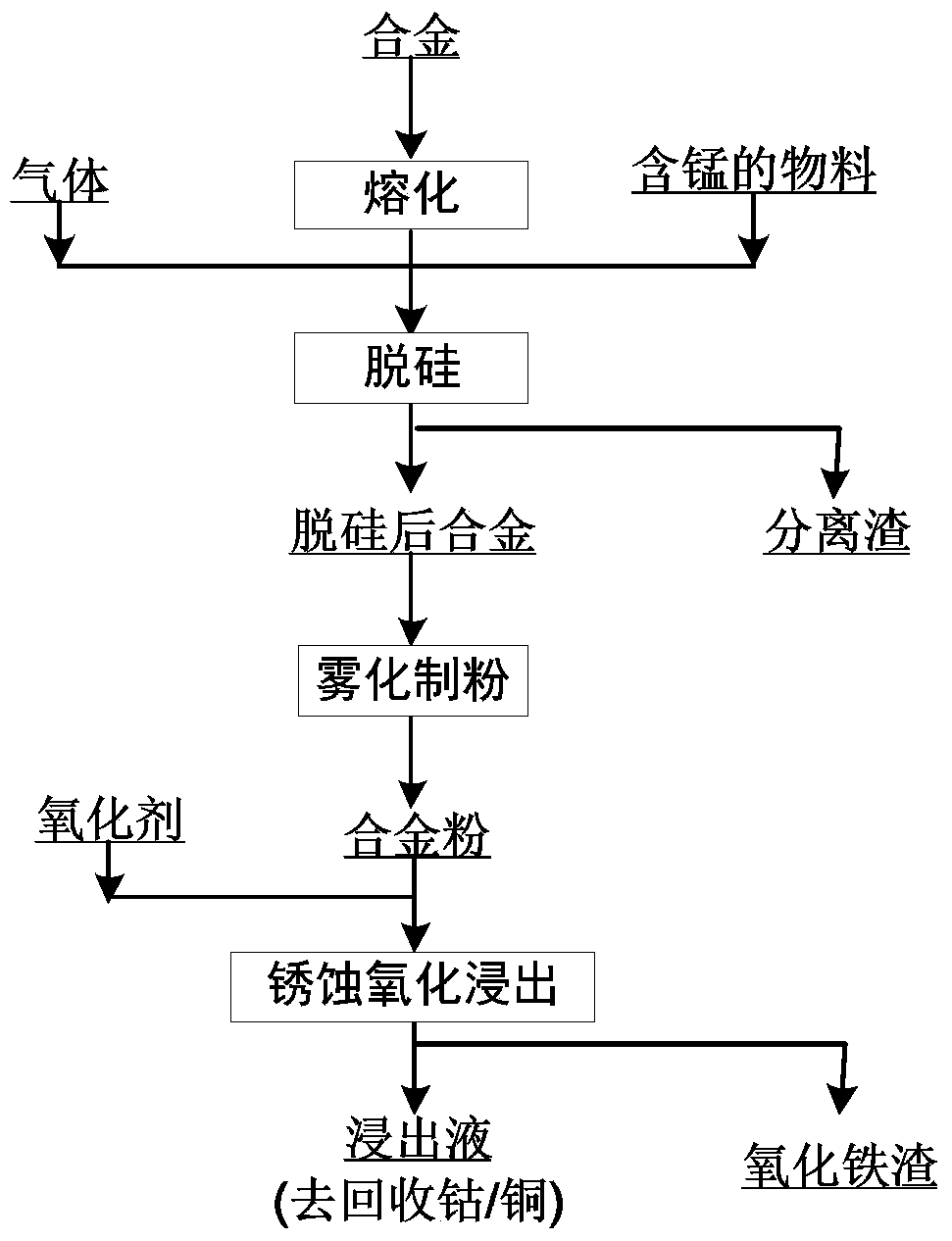

[0054] a kind of like figure 1 Shown the present invention reclaims the method for valuable metal from cobalt-copper white alloy, comprises the following steps:

[0055] (1) Put 800kg of cobalt-copper white alloy (mass content of main components are respectively Co 38.87%, Fe 32.45%, Cu13.45%, Si 10.15%) into a 1000kg intermediate frequency electric furnace for desiliconization quenching and tempering treatment, set the melting temperature At 1475°C, the cobalt-copper white alloy is melted to form an alloy melt.

[0056] (2) Add 20kg pyrolusite (Mn mass content 39.86%, SiO 2 mass content 13.33%), and at the same time feed nitrogen into the alloy melt (flow rate 10 ~ 25m 3 / h) blowing slagging (MnO-SiO 2 ), by controlling the appropriate oxygen partial pressure, the valuable metals copper, cobalt and iron in the furnace are hardly oxidized, while most of the manganese is oxidized.

[0057] (3) Separating the slagging generated in step (2) from the alloy melt.

[0058] (4) ...

Embodiment 2

[0061] a kind of like figure 1 Shown the present invention reclaims the method for valuable metal from cobalt-copper white alloy, comprises the following steps:

[0062] (1) Put 800kg of cobalt-copper white alloy (mass content of main components are Co 25.87%, Fe 40.05%, Cu15.45%, Si 15.16%) into a 1000kg intermediate frequency electric furnace for desiliconization quenching and tempering treatment, set the melting temperature At 1550°C, the cobalt-copper white alloy is melted to form an alloy melt.

[0063] (2) Add 5.0kg metal manganese (Mn content 99%) and 12.0kg manganese dioxide powder (MnO 2 content of 95%), and at the same time, a mixed gas of air and oxygen is passed into the surface of the alloy melt (wherein the air flow rate is 12m 3 / h, oxygen flow rate 5m 3 / h,) for blowing slagging (MnO-SiO 2 ), by controlling the appropriate oxygen partial pressure, the valuable metals copper, cobalt and iron in the furnace are hardly oxidized, while most of the manganese is ox...

Embodiment 3

[0068] a kind of like figure 1 Shown the present invention reclaims the method for valuable metal from cobalt-copper white alloy, comprises the following steps:

[0069] (1) Put 40kg of cobalt-copper white alloy (mass content of main components are Co 33.83%, Fe 37.10%, Cu16.88%, Si 5%) into a 50kg intermediate frequency electric furnace for desiliconization quenching and tempering treatment, set the melting temperature At 1430°C, the cobalt-copper white alloy is melted to form an alloy melt.

[0070] (2) Add 6.0kg metal manganese (99% Mn content) at one time to the alloy melt, and simultaneously feed air into the alloy melt interior and surface (wherein the air flow rate is 2.5m 3 / h) blowing slagging (MnO-SiO 2 ), by controlling the appropriate oxygen partial pressure, the valuable metals copper, cobalt and iron in the furnace are hardly oxidized, while most of the manganese is oxidized.

[0071] (3) Slag removal once, the slag generated in step (2) is separated from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com