A kind of preparation method of glycyrrhizin liposome

A technology of licorice polysaccharides and liposomes, which is applied in the direction of liposome delivery, medical preparations of non-active ingredients, pharmaceutical formulas, etc., can solve the problems that the preparation of licorice polysaccharide liposomes does not have too much guiding value, and achieve a solution Adhering to the wall, avoiding the effect of not being easy to dissolve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 Ethanol injection method prepares GUPL

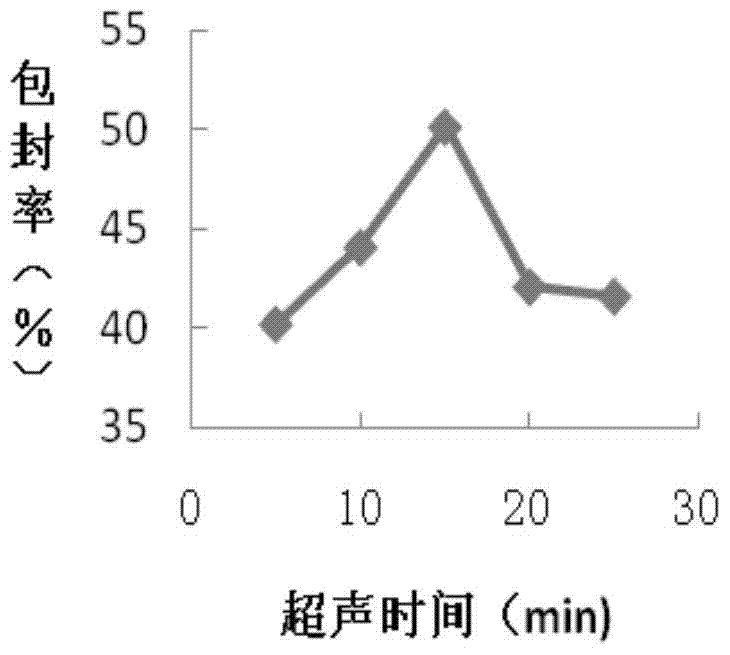

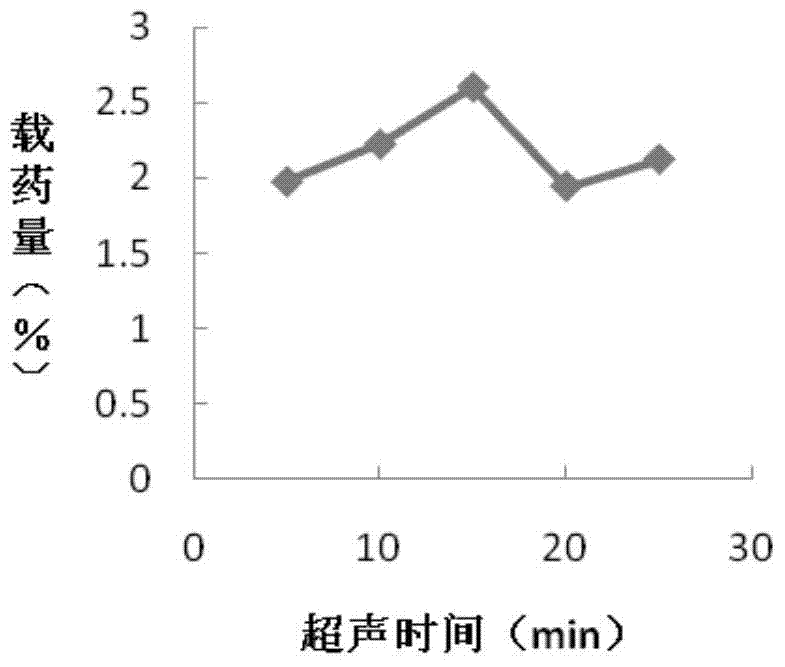

[0052] Accurately weigh 0.4g of soybean lecithin, 0.05g of cholesterol and 800.1g of Tween, dissolve it in 10mL of absolute ethanol, and ultrasonically dissolve it fully; -1 The PBS (pH 7.4) solution of licorice polysaccharide was slowly introduced into the former, kept at 45°C and continued to shake for 30 minutes; placed in a 250mL round bottom flask, evaporated under reduced pressure at 50°C to remove ethanol, and then placed in an ultrasonic cell pulverizer for ultrasonic treatment (intensity 40% , open in 2.5s, stop in 2.5s, and act for 15min), so that the glycyrrhizic polysaccharide is fully and evenly integrated into the liposome, and also makes the particle size of the glycyrrhizic polysaccharide liposome more uniform, thereby obtaining the glycyrrhizic polysaccharide liposome suspension Then extrude it respectively through microporous membranes with pore diameters of 0.45 μm and 0.22 μm, respectively repeati...

Embodiment 2

[0054] Embodiment 2 film dispersion method prepares GUPL

[0055] Accurately weigh 0.4g of soybean lecithin, 0.05g of cholesterol and 800.1g of Tween, dissolve it in 10mL of chloroform and methanol (1:1) solution, and ultrasonically dissolve it fully; place it in a 250mL round bottom flask, and evaporate it under reduced pressure at 50°C Organic solvent, when a uniform film is formed on the wall of the flask, introduce 20mL of -1 The PBS (pH 7.0) solution of licorice polysaccharide was evaporated under reduced pressure at 50°C to elute the bottle wall film; hydrated at 25°C for 0.5h; then placed in an ultrasonic cell pulverizer for ultrasonic treatment (intensity 40%, 2.5s on, 2.5 s stop, and act for 15min), the glycyrrhizic polysaccharide is fully and evenly fused in the liposome, and the particle diameter of the glycyrrhizic polysaccharide liposome is also made more uniform simultaneously, thereby obtains the glycyrrhizic polysaccharide liposome suspension; Then it is squeez...

Embodiment 3

[0057] Embodiment 3 Ammonium sulfate gradient method prepares GUPL

[0058] Accurately weigh 0.4g of soybean lecithin, 0.05g of cholesterol and 800.1g of Tween, dissolve it in 10mL of absolute ethanol, and ultrasonically dissolve it fully; under the vibration of a water bath shaker at 50°C, introduce the former into 10mL of 10% ammonium sulfate solution , then placed in a 250mL round-bottomed flask, evaporated under reduced pressure at 50°C to remove the organic solvent; dialyzed in PBS (pH 7.0) for 24h; -1 The PBS (pH 7.0) solution of licorice polysaccharide was slowly introduced into the former, kept at 50°C and continued to shake for 30 minutes; then placed in an ultrasonic cell pulverizer for ultrasonic treatment (intensity 40%, 2.5s on, 2.5s off, 20 minutes of action), so that the licorice polysaccharide Fully and evenly fused into the liposomes, and at the same time make the particle size of the licorice polysaccharide liposomes more uniform, so as to obtain the licorice...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com