Bioabsorbable bone repair material and its use and manufacturing method

A bone repair and biological technology, applied in the field of artificial prosthesis, can solve the problems of poor mechanical strength, difficult processing, and poor toughness of polylactic acid materials, achieve good biocompatibility, avoid side effects, and enhance the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

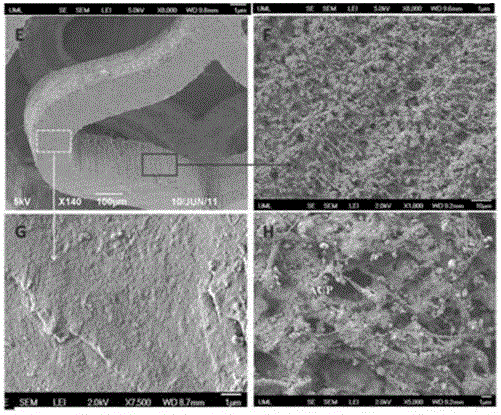

[0042] A bioabsorbable skull repair material, the composition of the skull repair prosthesis is a compound of 10kg of bioabsorbable polyester polymer (polyglycolide) and 90kg of calcium phosphate (amorphous calcium phosphate (ACP)) .

[0043] The composite material constituting the absorbable skull prosthesis can be obtained by polymer and nano-processing techniques, such as high-speed mixer, twin-screw extruder extrusion, etc., or by chemically suspending nanoparticles in polymer materials.

[0044] The preparation method of the prosthetic bone is an injection molding method:

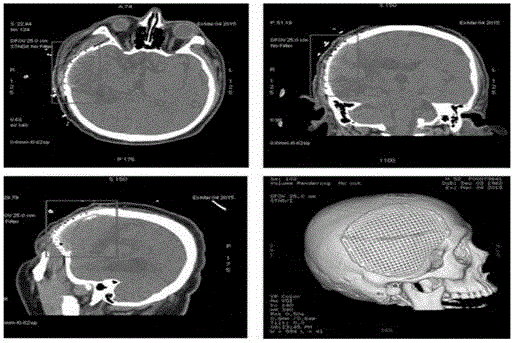

[0045] A. Digitize the CT / MRI image of the injured skull and convert it into a CAD file;

[0046] B. On the injection molding machine, according to the above-mentioned transformed CAD file, the above-mentioned bioabsorbable bone repair material is injected into a model of the damaged skull;

[0047] The prepared resorbable skull is coated with bone growth-inducing substances (damaging the patient's o...

Embodiment 2

[0049] A bioabsorbable bone repair material, the composition of the skull repair prosthesis is a composite of 20kg of bioabsorbable polyester polymer (polylactic acid (PLA)) and 80kg of calcium phosphate (dicalcium phosphate (DCP)).

[0050] The composite material constituting the absorbable cranial prosthesis can be obtained by polymer and nano-processing technology, such as high-speed mixer, twin-screw extruder extrusion, etc., or by chemically suspending nanoparticles in polymer materials.

[0051] The preparation method of the prosthetic bone:

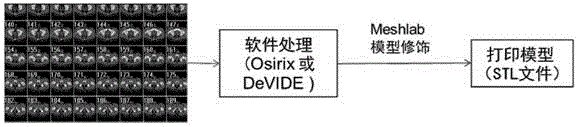

[0052] A. Convert the CT / MRI image data of the injured skull into STL files with open source software, or other files recognizable by 3D printers, and establish a model of the injured skull;

[0053] B. Processing the bioabsorbable bone repair material into a wire that can be used by a 3D printer.

[0054] C. Use the melting and sintering method to process the wire material in B, and according to the model established in A, sinter...

Embodiment 3

[0057] A bioabsorbable bone repair material, the composition of the skull repair prosthesis is a composite of 30kg of bioabsorbable polyester polymer (poly-L-lactic acid (PLLA)) and 70kg of calcium phosphate (tricalcium phosphate (TCP)) .

[0058] The preparation method is the same as in Example 1, and the prepared absorbable skull bone fragment is implanted into the injured skull of the patient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com