Mulberry bark powder, as well as preparation method and application of mulberry bark powder

A technology of mulberry bark powder and bark powder, which is applied in application, food preparation, food science and other directions to achieve the effects of good taste, simple preparation process and extended shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1. Preparation of ultrafine mulberry powder

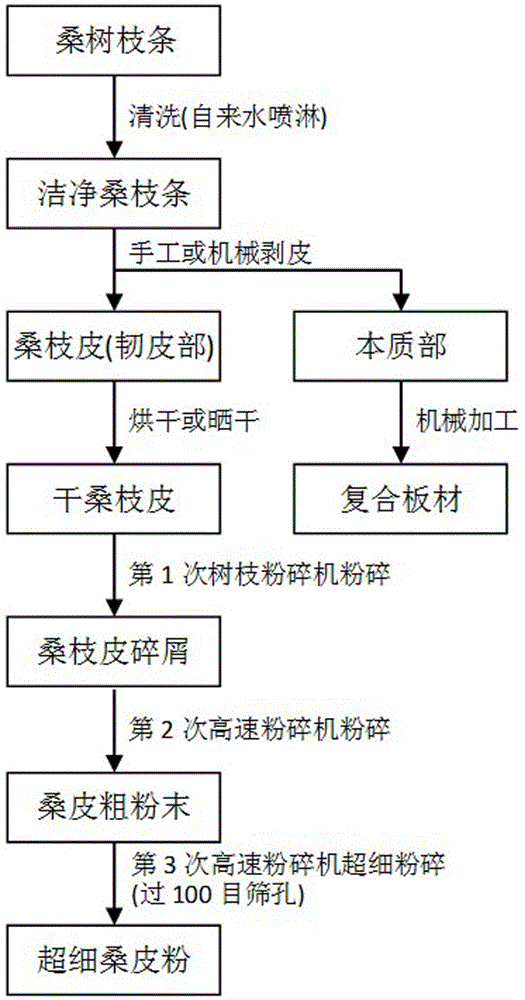

[0017] See attached figure 1 , it is the preparation process flowchart of the mulberry bark powder provided by the present embodiment; After the annual branches or biennial branches leaves of the mulberry trees are removed, they are cut down manually or mechanically, and the harvested mulberry branches are rinsed with tap water, dried or dried, Carry out rough processing and pulverize into chips through a branch pulverizer, then carry out secondary pulverization with a high-speed pulverizer, and finally carry out a third ultrafine pulverization with a high-speed pulverizer of 100 mesh sieves to obtain 100 mesh ultrafine mulberry bark powder.

[0018] 2. Characteristics of mulberry powder

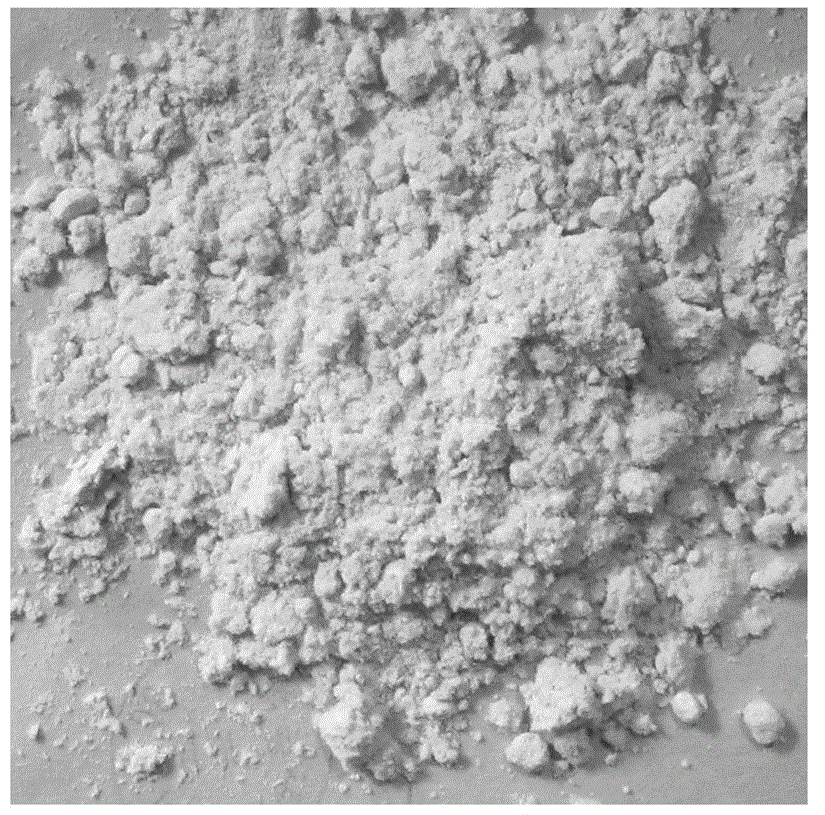

[0019] See attached figure 2 , it is the photo of the lake mulberry 32 mulberry powder (100 orders) that present embodiment provides, and the mulberry bark powder texture is fine and smooth, and under sunlight, the mulberry bark powder ...

Embodiment 2

[0028] Prepare mulberry powder according to the technical scheme of embodiment 1. In this embodiment, mulberry powder is used as a food additive and applied to the preparation of bread.

[0029] 1. Preparation of Mulberry Powder Bread

[0030] (1) Raw material formula

[0031] 350mL of water, 20g of vegetable oil (2 tablespoons), 7.5g of salt (1.5 teaspoon), 504g of high-gluten bread flour, 56g of mulberry bark powder, 3g of active dry yeast (1 teaspoon).

[0032] (2) Preparation process

[0033] Add 350mL of water, 20g of vegetable oil (2 tablespoons), 7.5g of salt (1.5 teaspoon), 504g of high-gluten bread flour, 56g of mulberry powder, and 3g of active dry yeast (1 teaspoon) into the bread machine in sequence ( Philips household bread machine model HD9016), set to the white bread making program, 4 hours of stirring fermentation and baking, after the bread is made, the bread is naturally cooled, and the mulberry powder bread is made.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com