Ce, Tb and Mn-coactivated single-matrix phosphate white phosphor powder and preparation method thereof

A single-matrix, phosphate technology, applied in the field of materials science, can solve the problems of difficult confirmation of phase and structure, high temperature for white light phosphor preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

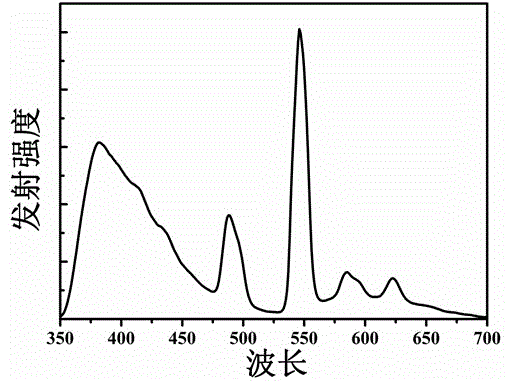

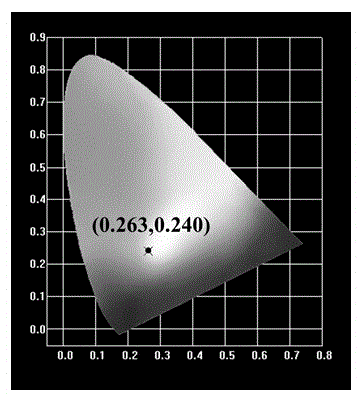

[0015] Preparation of Ba 1.92 Mg(PO 4 ) 2 :0.04Ce 3+ ,0.01Tb 3+ ,0.01Mn 2+ .

[0016] Weigh 2.0668g of barium carbonate, 0.5411g of basic magnesium carbonate, 0.0767g of cerium oxide, 0.0208g of terbium oxide, 0.0128g of manganese carbonate, and 1.2817g of ammonium dihydrogen phosphate, grind and mix them in a mortar for 120min, then add alcohol and grind for 60min to obtain The mixture, the mixture was put into a crucible boat and placed in a tube furnace with two temperature zones, calcined at 1100° C. for 5 hours under an aluminum reducing atmosphere, cooled naturally and ground into powder.

Embodiment 2

[0018] Preparation of Ba 1.74 Mg(PO 4 ) 2 :0.04Ce 3+ ,0.03Tb 3+ ,0.06Mn 2+ .

[0019] Weigh 1.9193g of barium carbonate, 0.5429g of basic magnesium carbonate, 0.1458g of cerium nitrate, 0.0289g of terbium nitrate, 0.0771g of manganese carbonate, and 1.2859g of ammonium dihydrogen phosphate, grind and mix in a mortar for 120min, then add alcohol and grind for 60min The obtained mixture was put into a crucible boat and placed in a double temperature zone tube furnace, calcined at 1100° C. for 5 hours under an aluminum reducing atmosphere, cooled naturally and ground into powder.

Embodiment 3

[0021] Preparation of Ba 1.72 Mg(PO 4 ) 2 :0.2Ce 3+ , 0.1Tb 3+ , 0.3Mn 2+ .

[0022] Weigh 0.9564g of barium carbonate, 0.5884g of basic magnesium carbonate, 0.4171g of cerium oxide, 0.2265g of terbium oxide, 0.4178g of manganese carbonate, and 1.3937g of ammonium dihydrogen phosphate, grind and mix in a mortar for 120min, then add acetone and grind for 10min After the mixture is obtained, the mixture is put into a crucible boat and placed in a double temperature zone tube furnace, calcined at 1000° C. for 10 hours under an aluminum reducing atmosphere, cooled naturally and ground into powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com