Method for reducing content of glycidyl ester in edible oil by using adsorbent

A technology of glycidyl ester and edible oil, which is applied in the direction of edible oil/fat, application, food science, etc., can solve the problems of difficulty in controlling the quality consistency of raw materials, low removal rate of glycidyl ester, and complicated implementation, etc., to achieve Convenient for industrial production, no solvent residue, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

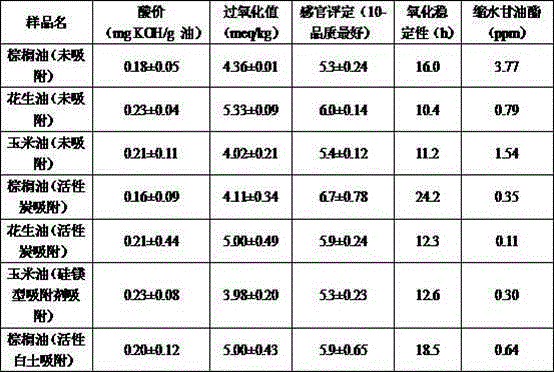

[0023] In a 100mL beaker, add 20g of palm oil, and at the same time add 2% of the weight of palm oil special activated carbon for edible oil, then use a constant temperature oil bath to quickly raise the temperature to 100°C, and react for 30min under rapid stirring at a speed of 10rpm. After the reaction was completed, it was filtered at 100°C to obtain a light yellow transparent liquid. The oxidative stability of the oil after adsorption is better than that before adsorption. Other indicators such as acid value and peroxide value are in line with national standards. After adsorption by special activated carbon for edible oil, the content of glycidyl ester in palm oil has increased from 3.7ppm It is reduced to about 0.3ppm, and the removal rate is above 92%. The specific experimental data are shown in Table 1.

[0024] Table 1

[0025]

Embodiment 2

[0027] In a 100mL beaker, add 20g of peanut oil, and at the same time add 5% of the weight of peanut oil special activated carbon for cooking oil, then use a constant temperature oil bath to quickly heat up to 100°C, and react for 60min under rapid stirring at a speed of 15rpm. After the reaction was completed, it was filtered at 100°C to obtain a yellow transparent liquid. The oxidative stability of the oil after adsorption is better than that before adsorption, and other indicators such as acid value and peroxide value are in line with national standards. After adsorption by special activated carbon for edible oil, the content of glycidyl ester in peanut oil is reduced from about 0.8ppm It is reduced to about 0.1ppm, and the removal rate is above 86%. The specific experimental data are shown in Table 1.

Embodiment 3

[0029] In a 100mL beaker, add 20g of corn oil, and at the same time add 10% of the weight of the corn oil as a silicon-magnesium-type adsorbent, then use a constant temperature oil bath to rapidly raise the temperature to 80°C, and react for 90min under rapid stirring at a speed of 20rpm. After the reaction was completed, it was filtered at 80°C to obtain a light yellow transparent liquid. The oxidative stability of the oil after adsorption is better than that before adsorption. Other indicators such as acid value and peroxide value are in line with national standards. About ppm is reduced to about 0.3ppm, and the removal rate is above 80%. The specific experimental data are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com