Method for pretreating non-lumber fibrous materials by utilizing basic salt in combination with hydrogen peroxide

A non-wood fiber, alkaline salt technology, applied in biosynthesis, biofuel, fermentation, etc., to reduce the pressure on the environment and energy, and create economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: take bamboo shoot skin as raw material pretreatment and enzymatic hydrolysis method.

[0039] Wash and air-dry the spring bamboo shoots, crush them to less than 5mm for later use. Cellulase (SpezymeCP, enzyme activity 110FPU / mL), β-glucosidase (Novozyme188, 603CBU / mL) and xylanase (MultifectXylanase, 1600FXU / mL), were purchased from Sigma (St.Louis, MO), Provided by Genencor Enzyme Company, USA. Use acetic acid-sodium acetate buffer (pH4.8) to make cellulase, xylanase and β-glucosidase at an enzyme activity ratio of 1FPU:1FXU:2CBU to prepare a mixed enzyme solution, and the enzyme activity of the mixed enzyme solution is Filter paper enzyme activity calculation.

[0040] Pretreatment process:

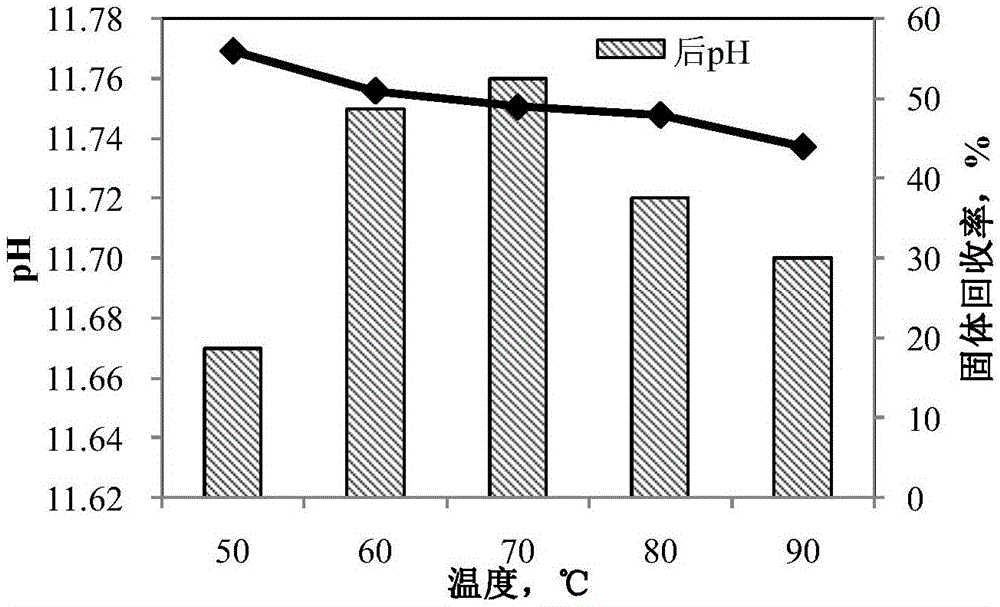

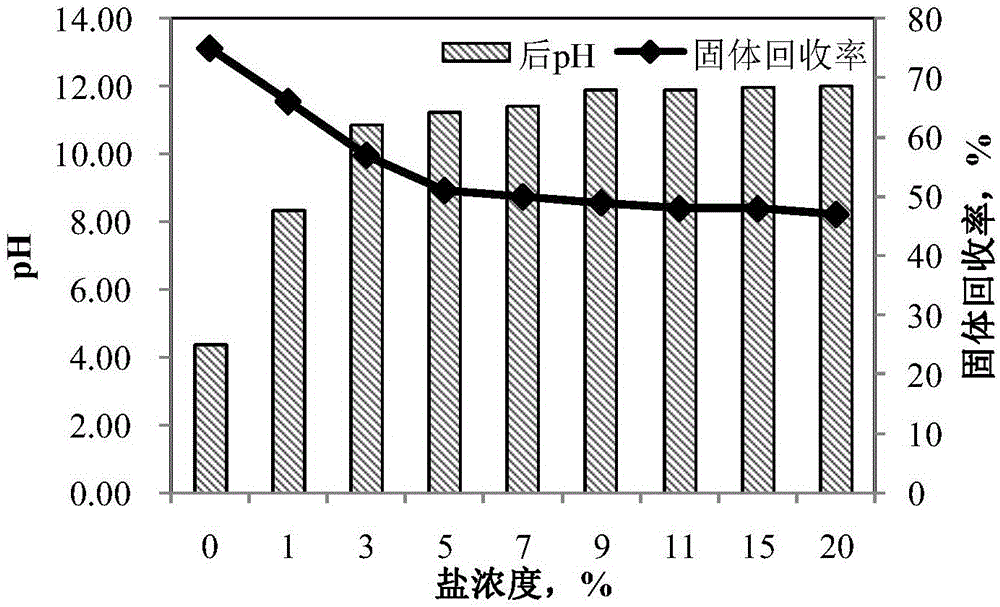

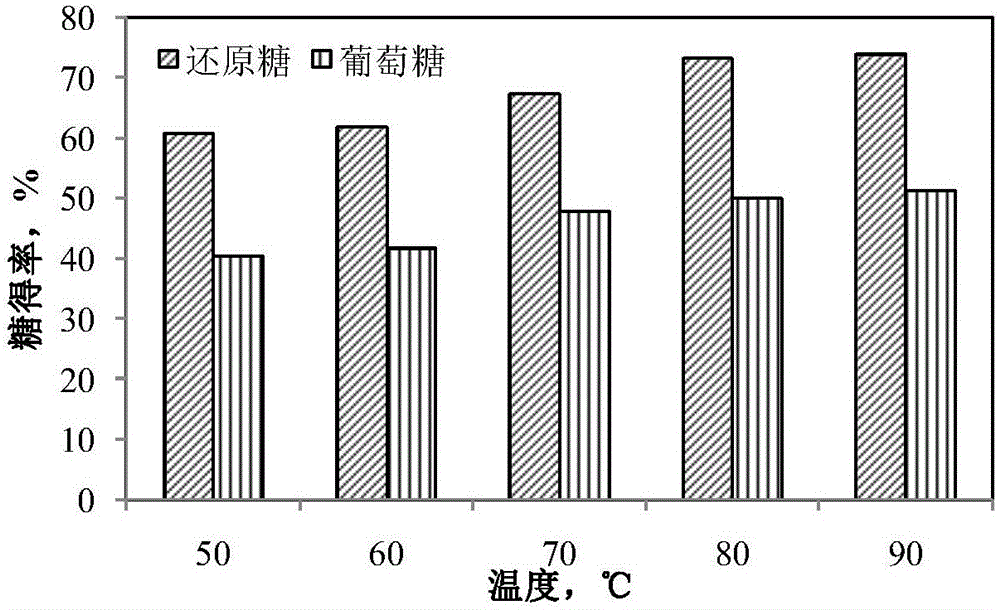

[0041] Weigh 1g of air-dried spring bamboo shoots and put them into a round bottom flask, add 20mL mixed solvent (i.e. substrate concentration 5g / L), wherein the mixed solvent is 1%H 2 o 2 and 1, 3, 5, 7, 9, 11, 15 and 20% Na 3 PO 4, stirred and reacted at ...

Embodiment 2

[0045] Embodiment 2: Pretreatment method and enzymatic hydrolysis method using corn stalks as raw materials.

[0046] The corn stalks are washed and air-dried, crushed to a size less than 5 mm for later use. Mixed enzyme liquid is identical with embodiment 1.

[0047] Weigh 1g of air-dried corn stalks into a round bottom flask, add 5mL of mixed solvent (i.e. substrate concentration 20g / L), the mixed solvent is 10%H 2 o 2 and 20%Na 3 PO 4 , stirred and reacted at 120° C. for 1 h, after the reaction was completed, add 2 times the volume of deionized water and stirred at room temperature for 30 min to regenerate the cellulose raw material. Then filter and wash, and put the solid residue in a sealed plastic bag for later use. The enzymatic hydrolysis process is the same as in Example 1, wherein the compound enzyme is 30 FPU / (g substrate). After the above pretreatment and enzymatic hydrolysis, the final reducing sugar yield and glucose yield were 70.71% and 51.01%, respecti...

Embodiment 3

[0048] Embodiment 3: the pretreatment method and the enzymatic hydrolysis method using spring bamboo skin as raw material.

[0049] Wash and air-dry the spring bamboo shoots, crush them to less than 5mm for later use. Mixed enzyme liquid is identical with embodiment 1.

[0050] Weigh 1g of air-dried spring bamboo shoot skin into a round bottom flask, add 10mL of mixed solvent (i.e. substrate concentration 10g / L), wherein the mixed solvent is 5% H 2 o 2 and 9%Na 3 PO 4 , stirred and reacted at 50° C. for 6 hours, after the reaction was completed, an equal volume of deionized water was added and stirred at room temperature for 30 minutes to regenerate the cellulose raw material. Then filter and wash, and put the solid residue in a sealed plastic bag for later use. The enzymatic hydrolysis process is the same as in Example 1, wherein the compound enzyme is 30 FPU / (g substrate). Through the above pretreatment and enzymatic hydrolysis, the final reducing sugar yield and glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com