High-medium single-layer miniature ceramic capacitor substrate material and preparation method thereof

A ceramic capacitor and high-dielectric single-layer technology, applied in the field of electronic information functional materials, can solve the problems of non-dense structure, unfriendly environment, poor material performance uniformity, etc., and achieve the effect of sufficient supply and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

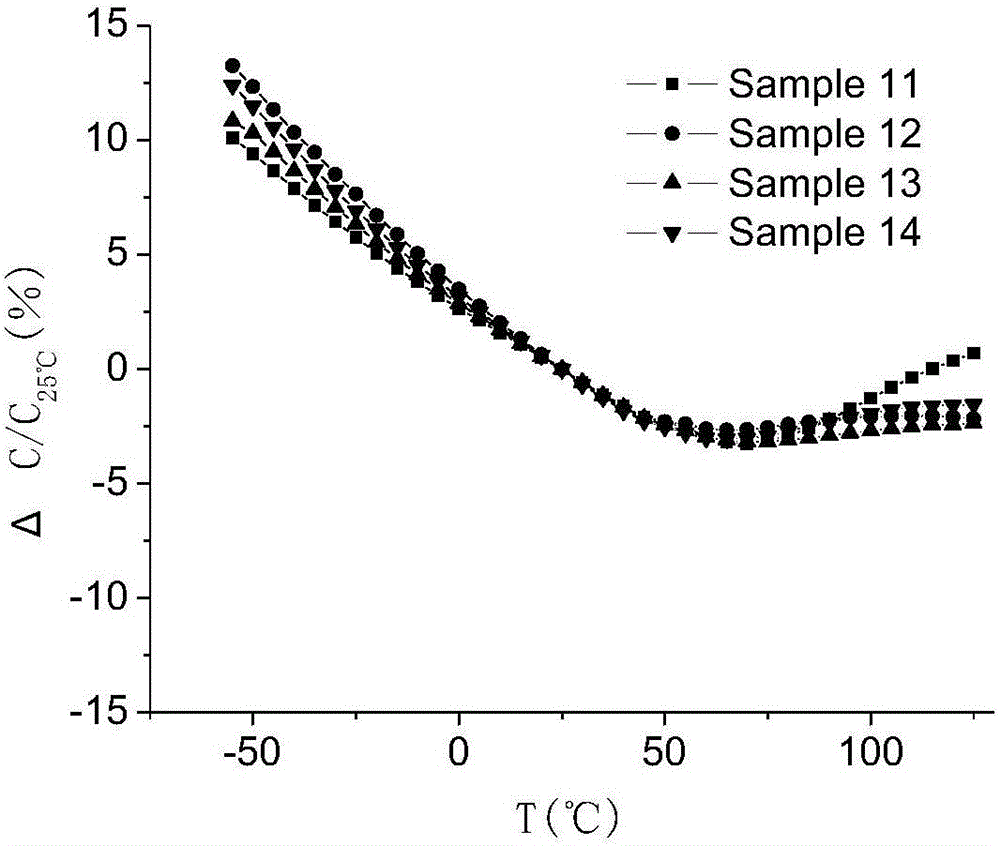

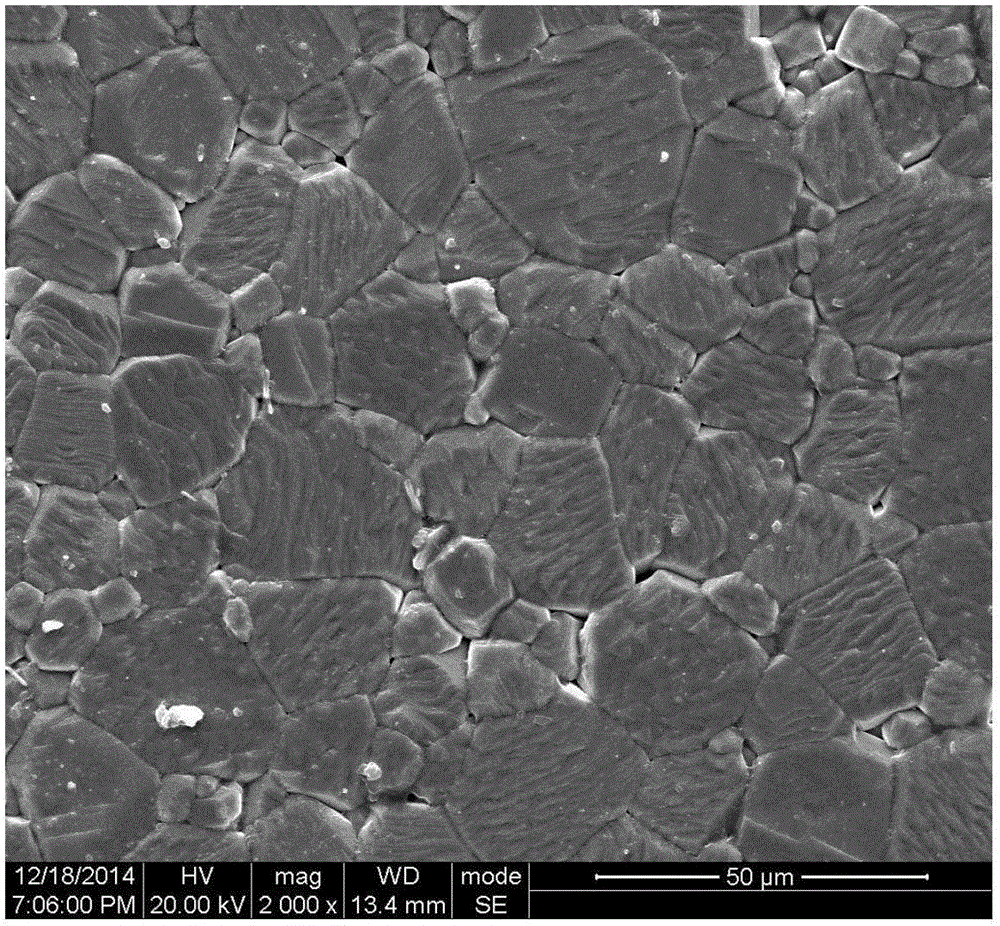

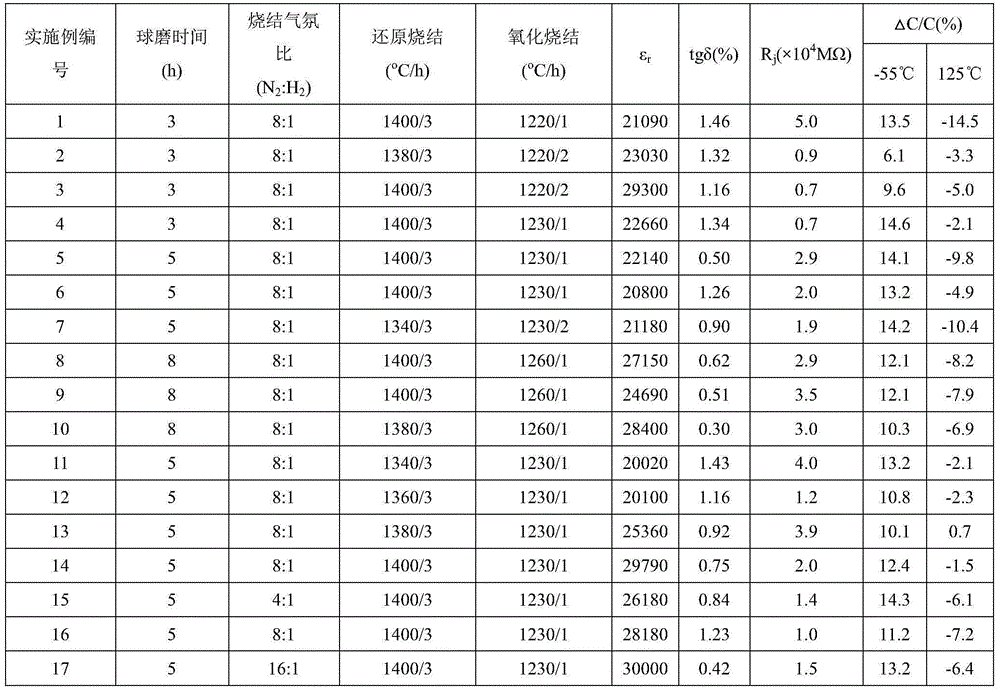

Examples

Embodiment 1~17

[0057] The preparation method of the above-mentioned high-dielectric single-layer micro-ceramic capacitor substrate material comprises the following steps:

[0058] (1.0) Preparation of composite oxide additive:

[0059] ①Select SrCO 3 , MnO 2 、TiO 2 , SiO 2 and B 2 o 3 As a raw material, prepare the material according to the above ratio, ball mill the prepared material with deionized water as the medium, dry it at 100°C-120°C and pass it through a 40-mesh sieve;

[0060] ②Dry and pass through a 40-mesh sieve, and pre-calcine the ball abrasive at 600°C-800°C for 1-2 hours to obtain the composite oxide additive powder.

[0061] (1.1) Ingredients

[0062] SrTiO 3 As the main material, add the above content of Nb respectively 2 o 5 , SiO 2 , Y 2 o 3 , CaSnO 3 and composite oxide additives are mixed to obtain a mixture;

[0063] (1.2) Ball mill

[0064] The mixture prepared in step 1.1 was ball milled, and after ball milling, the ball mill was dried at 120° C. and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com