Method for preparing 5-hydroxymethylfurfural by taking galactose as base material

A hydroxymethylfurfural and galactosyl technology, which is applied in the field of preparing the platform compound 5-hydroxymethylfurfural (5-HMF), can solve the problems of harsh operating conditions, difficulty in actual production, and high cost, and achieves equipment and The effect of low environmental requirements and simple and easy preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 100, 200, 300, 400, 500, 600, 800 grams of galactose respectively, add water to 1 liter to obtain galactose solutions of different concentrations; weigh 120 grams of calcium hydroxide solids, slowly stir and add half In the lactose solution, the isomerization reaction was carried out at 20°C for 20 hours, and yellow gelatinous products were obtained after the reaction. Put each yellow colloidal product in a water bath at 20°C, slowly stir and add phosphoric acid to adjust the pH to 1.5, centrifuge to remove the precipitate, and obtain a supernatant.

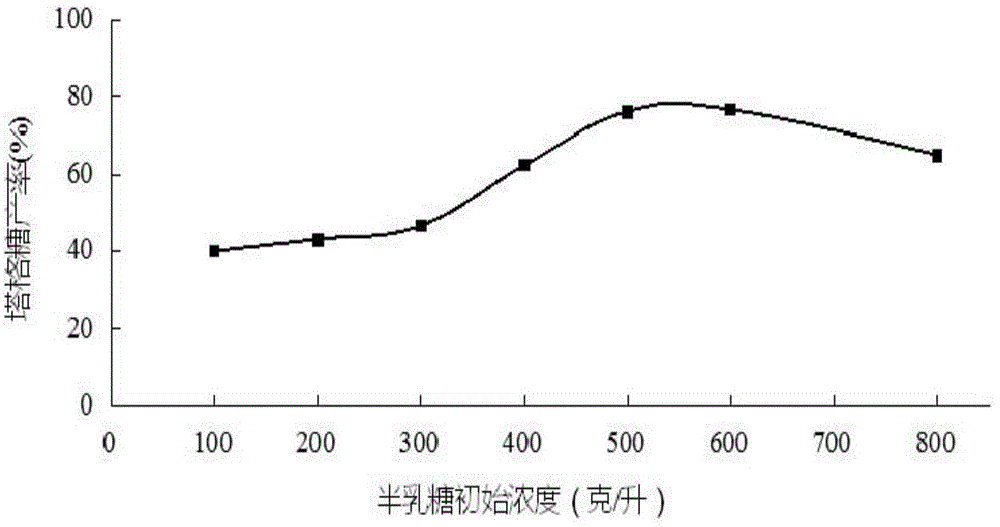

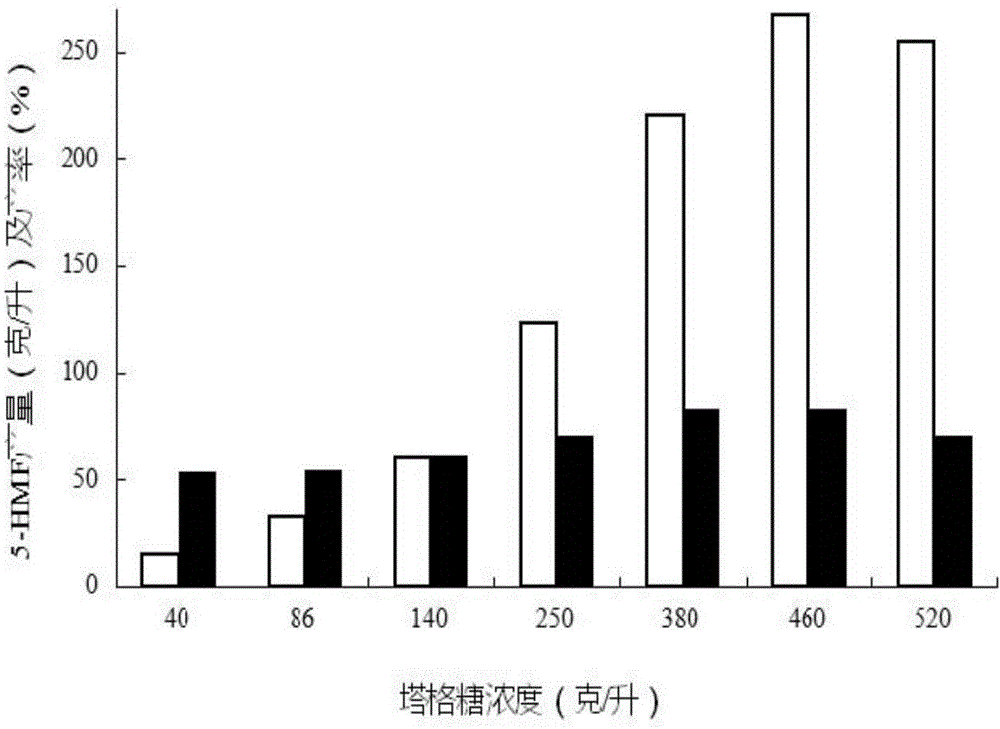

[0038] The contents of galactose and tagatose in each supernatant were determined by HPLC, and the results showed that galactose in each supernatant was completely consumed, and the concentrations of tagatose were 40 g / L, 86 g / L, and 140 g / L, respectively. liter, 250 g / l, 380 g / l, 460 g / l, 520 g / l. That is, the yield of tagatose obtained by isomerization of galactose at various concentrations is as follows figure 1...

Embodiment 2

[0042]Weigh 500 grams of galactose and add water to 1 liter. Weigh 222 grams of calcium hydroxide solids and 111 grams of calcium chloride solids, add them to the galactose solution, and stir fully while adding, so that calcium hydroxide and calcium chloride solids are fully dispersed in the solution. Then, the isomerization reaction was allowed to stand in a water bath at 30° C. for 8 hours, and a yellow colloidal substance was obtained after the reaction. Place the yellow gelatinous substance in an ice-water bath at 0°C, slowly add 50% sulfuric acid aqueous solution, stir and dissipate heat while adding, adjust the pH to 1.0, and centrifuge to remove the precipitate to obtain a supernatant.

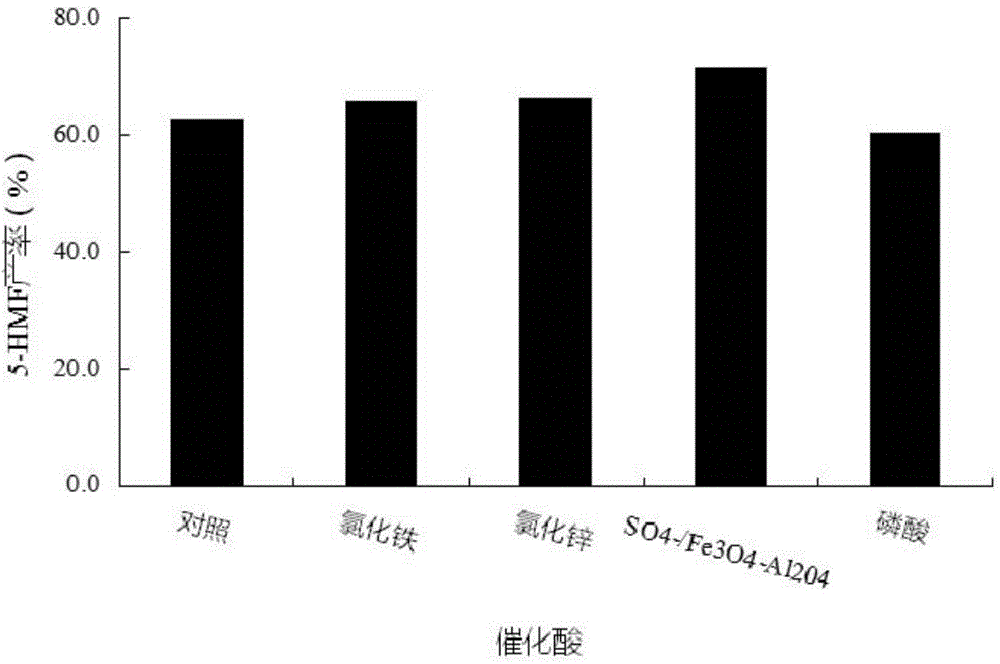

[0043] Divide the supernatant into 5 parts, each 200 ml, add ferric chloride, zinc chloride, SO 4 - / Fe 3 o 4 -Al 2 0 4 , 2 grams of phosphoric acid, —— (the “——” means no catalytic acid was added, for comparison with the aforementioned situation of adding catalytic acid), and the...

Embodiment 3

[0046] Add 60 kg of galactose to a 250L temperature-controlled reaction tank, add 100 liters of water to dissolve, slowly add 3.7 kg of calcium hydroxide solids, 0.2 kg of sodium sulfate, stir and disperse evenly with a stirrer, control the temperature at 20°C, and continuously stir for isomerization reaction for 10 hours, isomeric products were obtained. Control the temperature at 20°C, slowly pump 50% phosphoric acid aqueous solution into the isomer product at a rate of 1 liter / hour with a feed pump until the pH value is 2.0, stop adding acid, and continue stirring to dissipate heat during feeding. Then let it stand for 12 hours to fully precipitate, remove the precipitate and add 1.0 kg of SO to the supernatant 4 - / Fe 3 o 4 -Al 2 0 4 , react in a high-pressure reactor at 120° C. for 1 hour to obtain a post-reaction solution.

[0047] After HPLC detection, the galactose in the solution was exhausted after the reaction, that is, the conversion rate of galactose was 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com