Preparation of polypyrrole/gel alginate with three dimensional structure and electrical stimulation and pH response and double control drug release

A three-dimensional structure, double control technology, applied in the field of material synthesis and biomedicine, can solve the problems of limited application, and achieve the effect of simple and easy preparation method and delayed release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation of salicylic acid-doped polypyrrole nanoparticles / alginate hydrogel includes the following steps:

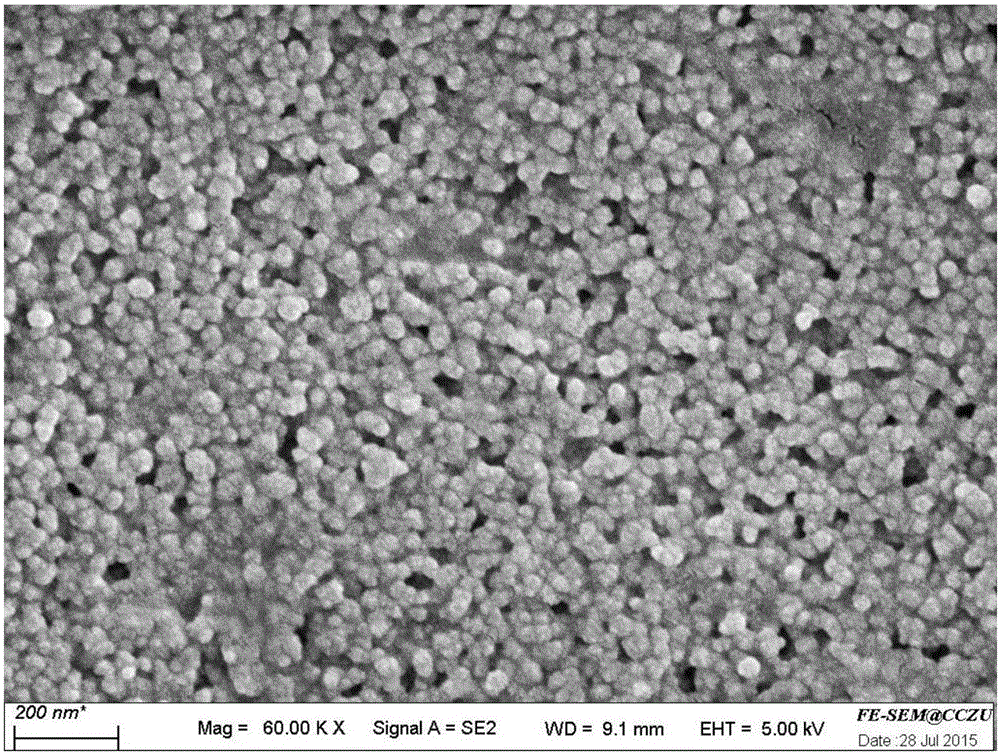

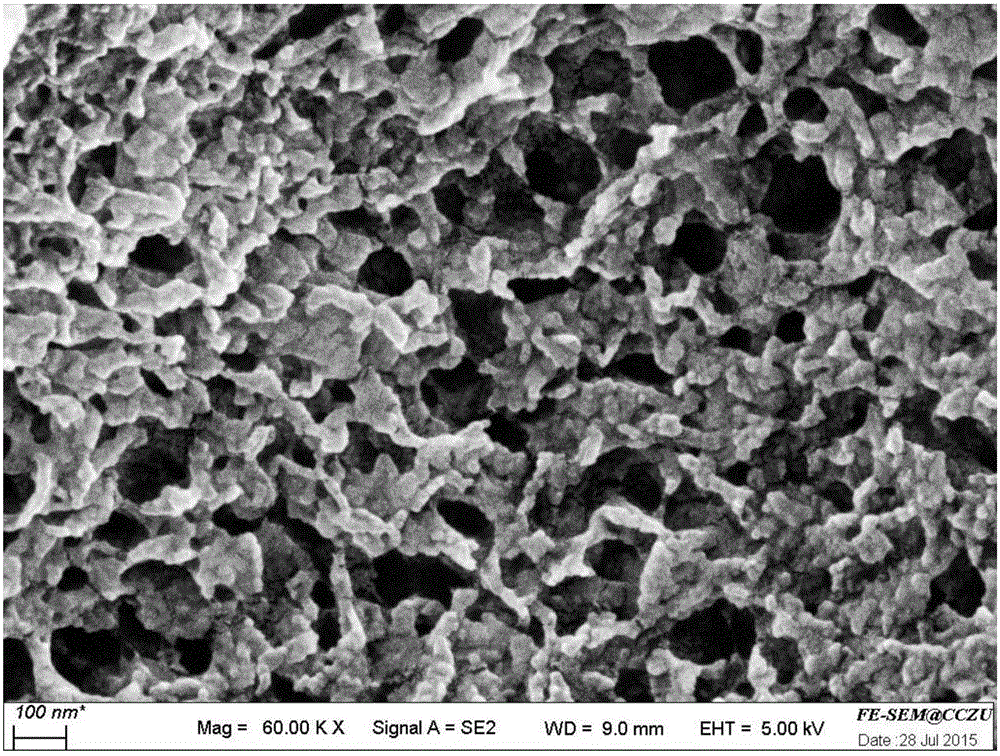

[0023] (1) Prepare 5 mL of an aqueous solution of 10 mmol / L salicylic acid, weigh 70 mg of sodium dodecylbenzene sulfonate, add it to the above solution and stir to dissolve. Pipette 0.4 mL of a mixed solution of pyrrole and cyclohexane (volume ratio 1:3) and add it dropwise to the above solution, place in an ice bath and magnetically stir for 1.5 h. After the reaction, the solution was ultrasonically treated for 5 min to form a microemulsion. Add 10% polyvinyl alcohol solution, stir evenly and place in ice bath. Add 10 mL of 0.15 mol / L ammonium persulfate aqueous solution dropwise to the microemulsion, and ice-bath for 24 h. After centrifugation and washing for 5 times, freeze-drying was carried out for 24 hours to obtain salicylic acid-doped polypyrrole nanoparticles. Its scanning electron microscope picture is as figure 1 As shown, the polypyrrole n...

Embodiment 2

[0026] The in vitro release behavior of drugs under different potential conditions includes the following steps:

[0027] The preparation process of salicylic acid-doped polypyrrole nanoparticles / alginate hydrogel is the same as that of Example 1.

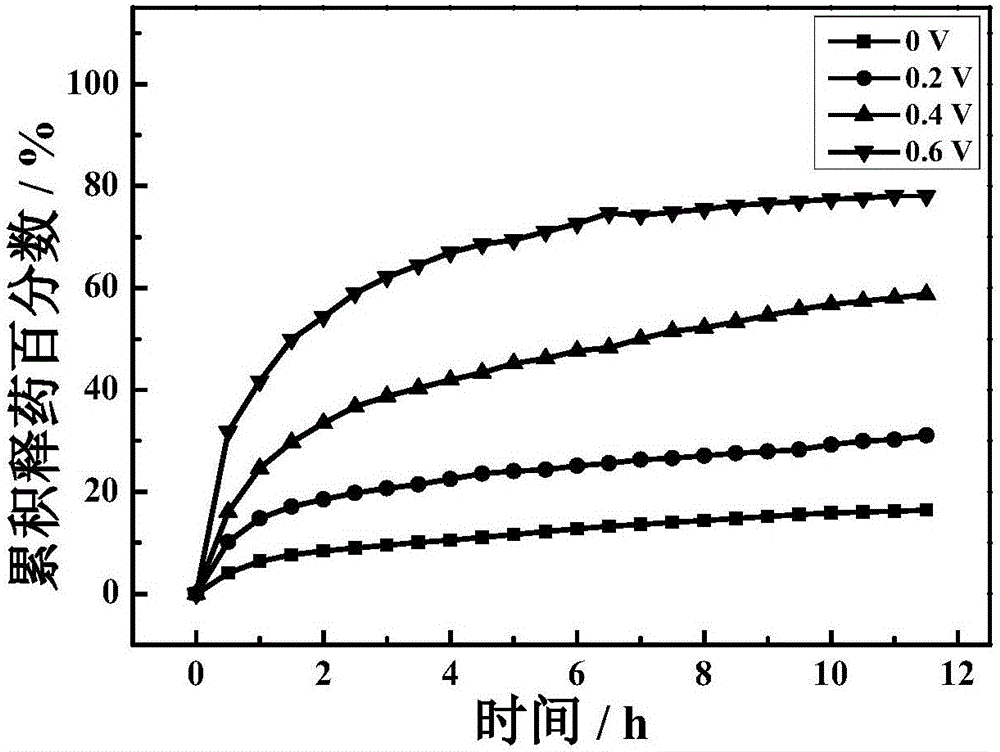

[0028] (1) Prepare 0.1mol / L phosphate buffer solution (PBS, containing 0.15mol / LNaCl, pH7.4) for simulating human environment, take 15mg of composite material, place it in a dialysis bag, and suspend the dialysis bag in 50mL Magnetic stirring was performed at a speed of 100 rpm in PBS, and electrical stimulation release was performed at 37°C. Drug release from the composite was performed using two stainless steel plates as conditions for applying an electric field. Adjust the electric field strength to 0V, 0.2V, 0.4V and 0.6V, release for 11.5h respectively;

[0029] (2) Draw 3mL of solution from the solution every 0.5h, measure the content of salicylic acid, and supplement the same volume of PBS at the same time. The content of...

Embodiment 3

[0031] The in vitro release behavior of drugs under different pH conditions includes the following steps;

[0032] The preparation process of salicylic acid-doped polypyrrole nanoparticles / alginate hydrogel is the same as that of Example 1.

[0033](1) Prepare 0.1mol / L phosphate buffered saline solution (PBS, containing 0.15mol / LNaCl) for simulating the human body environment, take 15mg of the composite material, place it in a dialysis bag, and suspend the dialysis bag in 50mL of PBS to Magnetic stirring was performed at a speed of 100 rpm, and electrical stimulation release was performed at 37°C. Adjust the pH of PBS to 3.4, 5.4, 7.4 and 9.4, release 11.5h respectively;

[0034] (2) Draw 3mL of solution from the solution every 0.5h, measure the content of salicylic acid, and supplement the same volume of PBS at the same time. The content of salicylic acid is measured at 298nm using ultraviolet spectrophotometry, and the cumulative drug release percentage at different times ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com