Method for producing L-ornithine by whole cell transformation of recombinant Corynebacterium crenatum

A technology of ornithine and recombinant bacteria, which is applied in the direction of recombinant DNA technology, bacteria, and the use of vectors to introduce foreign genetic materials, etc., can solve the problems of long fermentation cycle, high technology requirements, low fermentation yield, etc., and achieve product specificity Strong, high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

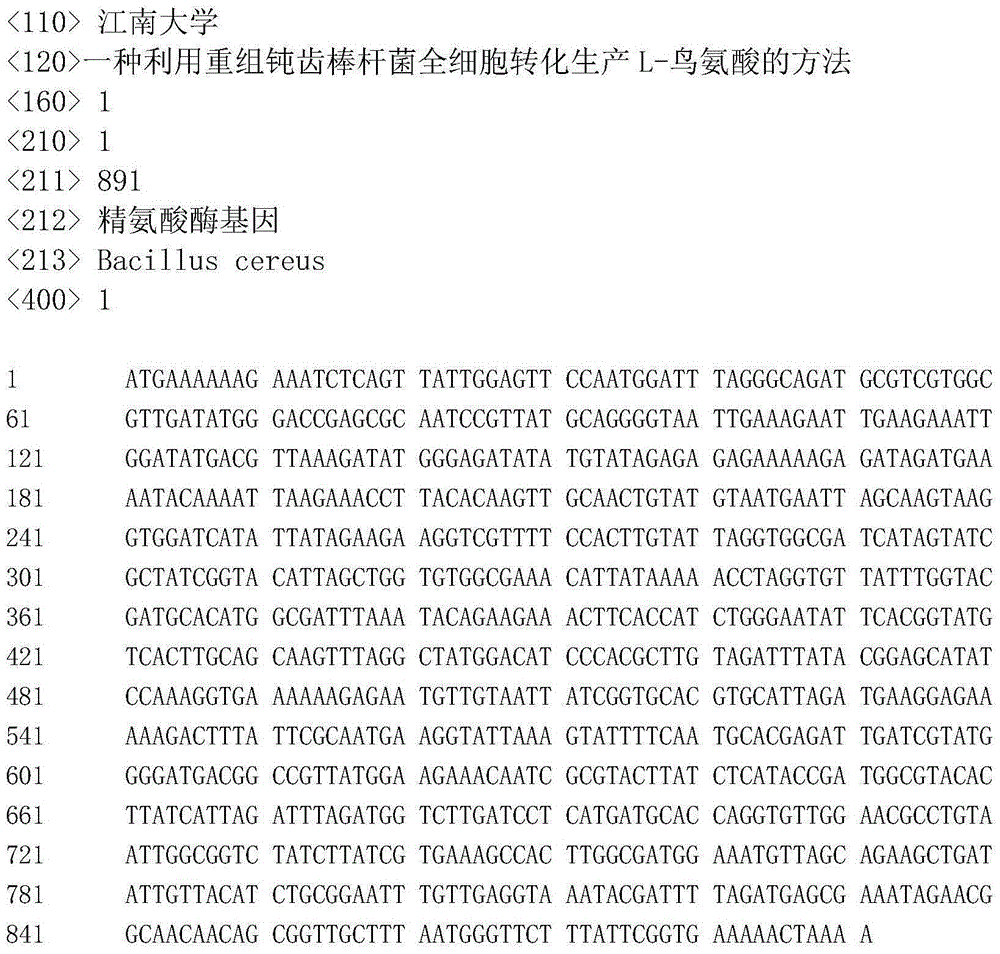

[0036] Example 1: Arginase Primer Design

[0037] According to the argI gene sequence in the whole genome nucleic acid sequence of Bacilluscereus in NCBI, the PCR primers P1 and P2 of the arginase gene were designed.

[0038] F: 5'-ACCCG AAGCTT ATGAAAAAAGAAATCTCAGTTATTGG-3'(HindIII)

[0039] R: 5'-ACCG GGATCC TTATTTTAGTTTTTCACCGAATAAAG-3' (BamHI)

Embodiment 2

[0040] Embodiment 2: the cloning of arginase gene

[0041] Using the total DNA of Bacilluscereus as a template, use the primers provided above for PCR amplification. The amplification conditions are: 94°C pre-denaturation, 5min, one cycle; 94°C denaturation, 1min, 56°C annealing, 1min, 72°C extension, 45s, 35 cycles; final extension at 72°C for 10 min. PCR amplification system: template 1 μL, upstream and downstream primers 0.4 μL, dNTPMix 4 μL, 10×ExTaqBuffer 5 μL, sterilized double distilled water 37 μL, ExTaq DNA polymerase 1 μL. The PCR product was purified and recovered using a gel recovery kit, and the concentration of the recovered product was checked by electrophoresis. The recovered product was stored in a 1.5ml centrifuge tube and stored in a -20°C refrigerator for later use. The recovered product was ligated with pMD18-TVector, and the ligated product was transformed into E.coilJM109, and the transformed product was coated on an LB plate containing ampicillin, cul...

Embodiment 3

[0042] Embodiment 3: Construction of recombinant plasmid pXMJ19-argI

[0043] Extract the plasmids pMD18-T-argI and pXMJ19 stored in E.coliJM109, and perform double enzyme digestion with BamHI and HindIII, respectively, and ligate after recovering with a gel recovery kit. Ligation system: 7 μL of digested product of the target gene, pXMJ19 Digest product 1 μL, T4 DNA ligase buffer 1 μL, T4 DNA ligase 1 μL, ligate overnight at 16°C. The connected recombinant plasmid pXMJ9-argI was transformed into competent E.coilJM109, and positive colonies were picked with LB chloramphenicol resistance medium. The plasmid was extracted after overnight culture on a shaker at 37°C and named pXMJ9-argI. After the enzyme digestion was verified to be correct, glycerol was added to a final concentration of 15%-20% (w / v), and stored in a -70°C refrigerator for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com