g-C3N4/TiO2@montmorillonite photocatalyst and preparation method thereof

A technology of g-c3n4, 1.g-c3n4 is applied in the field of montmorillonite composite g-C3N4/TiO2 heterojunction photocatalyst and its preparation, which can solve the problem of high requirements for reaction equipment, difficult recovery, easy agglomeration of catalysts, etc. problems, to achieve the effect of improving the utilization efficiency of visible light, reducing the application cost and being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

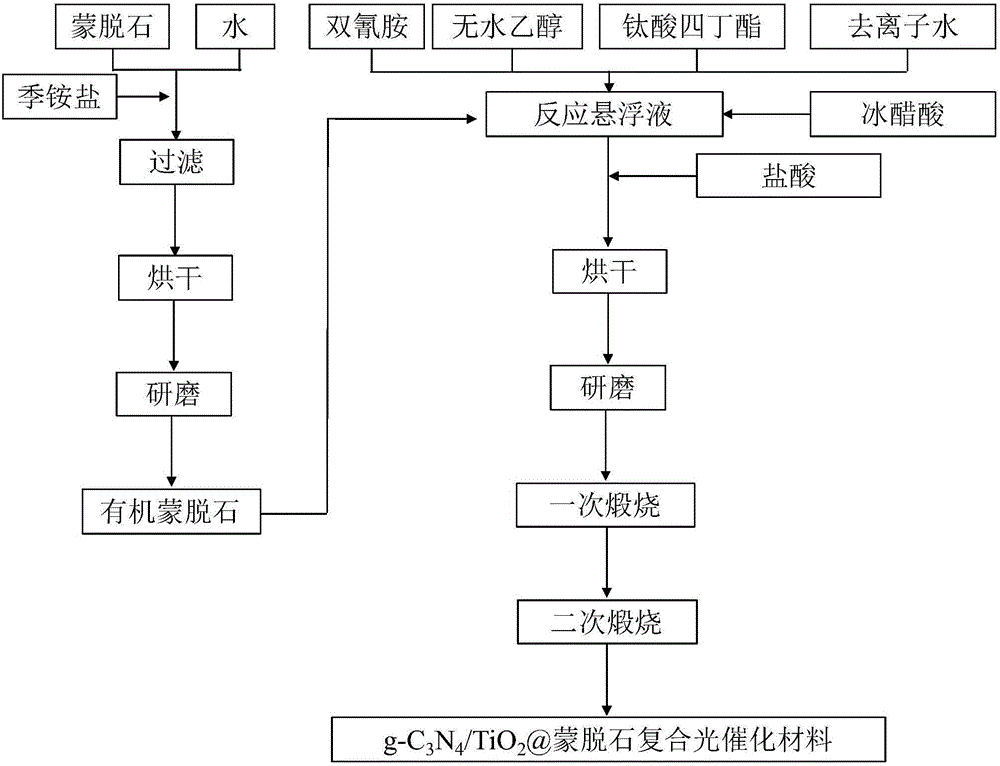

[0018] The specific implementation steps are as follows:

[0019] (1) Take 10g montmorillonite and disperse it in 200mL water for 30min to prepare montmorillonite suspension; then dissolve 1.0CEC of cetyltrimethylammonium bromide in water, and then add modifier solution to montmorillonite Ion exchange was carried out in the stone suspension, stirred and reacted at 30°C for 3 hours, dried in an oven at 105°C, and ground until 97% passed through a 200-mesh sieve.

[0020] (2) Take 24mL of absolute ethanol, add 2.8g of dicyandiamide, stir for 30min to form a homogeneous suspension, then add 2.0g of modified montmorillonite, continue stirring for 30min, then add 2mL of glacial acetic acid dropwise, and then add 3mL of titanium acid tetrabutyl ester to obtain a reaction suspension; use concentrated hydrochloric acid to adjust the pH value to 2.0, and peptize at room temperature for 12 hours.

[0021] (3) Dry at 105°C for 12 hours, grind to 97% and pass through a 200-mesh sieve, an...

Embodiment 2

[0024] Same as step in embodiment 1, difference is: the add-on of modifier didodecyl dimethyl ammonium bromide is 0.6CEC in the step (1), and the temperature of ion exchange is 25 ℃; Step (2 ) in the addition amount of dicyandiamide is 2.20g, and the addition amount of tetrabutyl titanate is 2.0mL; in step (3), the initial closed calcination temperature is 500°C, the calcination time is 3.5h, the heating rate is 2°C / min, and the second The open calcination temperature is 450°C, the calcination time is 2.5h, and the heating rate is 4.5°C / min.

Embodiment 3

[0026] Same as step in embodiment 1, difference is: the add-on of modifying agent cetyltrimethylammonium bromide is 0.8CEC in the step (1), and the temperature of ion exchange is 25 ℃; Step (2) The addition amount of dicyandiamide in the medium is 3.0g, the addition amount of tetrabutyl titanate is 2.5mL; in step (3), the initial closed calcination temperature is 520°C, the calcination time is 3h, the heating rate is 3.0°C / min, and the second open The calcination temperature is 400°C, the calcination time is 3.0h, and the heating rate is 4°C / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com