Non-metal material tray for garbage pyrolysis furnace rotating bed, and preparation method tehreof

The technology of a pyrolysis furnace and a rotating bed is applied to the non-metallic material tray for a rotating bed of a waste pyrolysis furnace and the field of its preparation, which can solve the problems of high load-bearing capacity of the beam, affecting the use performance, increasing power consumption and the like, and achieves thermal conductivity. Good performance, low power consumption, improved strength and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

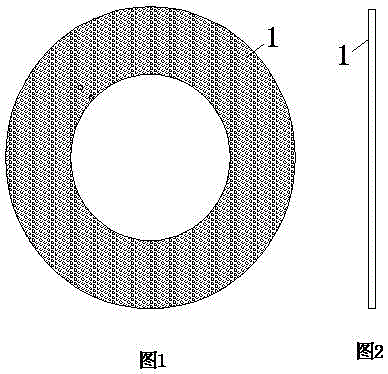

Image

Examples

Embodiment 1

[0024] The non-metallic material tray for the rotary bed of the garbage pyrolysis furnace is 60% of silicon carbide, 10% of silicon powder, 15% of silicon nitride, 4.0% of alumina micropowder, 3.0% of silicon dioxide, 1.0% of calcium oxide and nitrogen by weight. Boron chloride 1.0%, premixed as inorganic powder, the amount of additive added is calculated according to 100 parts by weight of inorganic powder, in the additive, organic binder ethyl cellulose CMC accounts for 3.5 parts by weight, plasticizer 1-1.5 parts by weight, The moisturizing agent is 1-1.5 parts by weight, and the water is 6 parts by weight.

[0025] During preparation, the inorganic powder is pre-mixed with solid raw materials such as binder, plasticizer, and humectant for 2 hours, then put into the mixer and add water while stirring, and the mixing time is more than 15 minutes, and then knead into mud for later use; The mud is initially refined on a vacuum mud refining machine. During the initial refining,...

Embodiment 2

[0027] The non-metallic material tray for the rotary bed of the garbage pyrolysis furnace is 60% of silicon carbide, 10% of silicon powder, 15% of silicon nitride, 4.0% of alumina micropowder, 3.0% of silicon dioxide, 1.0% of calcium oxide and nitrogen by weight. Boron chloride 1..5%, premixed as inorganic powder, the amount of additive added is calculated according to 100 parts by weight of inorganic powder, among the additives, the organic binder ethylcellulose CMC accounts for 3.5 parts by weight, and the plasticizer 1-1.5 parts by weight parts by weight, 1-1.5 parts by weight of the moisturizing agent, and 7 parts by weight of water.

[0028] During preparation, the inorganic powder is pre-mixed with solid raw materials such as binder, plasticizer, and humectant for 2 hours, then put into the mixer and add water while stirring, and the mixing time is more than 15 minutes, and then knead into mud for later use; The mud is initially refined on a vacuum mud refining machine. ...

Embodiment 3

[0030] Take 63% of silicon carbide, 18% of silicon powder, 6.0% of silicon nitride, 7.0% of alumina micropowder, 4.0% of silicon dioxide, 2.0% of calcium oxide and 2.5% of boron nitride by weight, pre-mixed as inorganic powder, Calculate the amount of additives added according to 100 parts by weight of inorganic powder. Among the additives, the organic binder ethylcellulose CMC accounts for 3.5 parts by weight, the plasticizer is 1-1.5 parts by weight, the humectant is 1-1.5 parts by weight, and water is 8 parts by weight. share.

[0031] During preparation, the inorganic powder is pre-mixed with solid raw materials such as binder, plasticizer, and humectant for 2 hours, then put into the mixer and add water while stirring, and the mixing time is more than 15 minutes, and then knead into mud for later use; The mud is initially refined on a vacuum mud refining machine. During the initial refining, the vacuum degree of the mud refining machine is -0.08MPa, and a relatively dense...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com