Method for preparing cookware coating free of perfluorooctane sulfonate

A fluorooctane sulfonate and preparation method technology, applied in polyether coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of easy peeling, reduced non-stick performance, dry burning, etc., and achieve stable chemical properties , long service life, avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method for a paint for cooking utensils without perfluorooctane sulfonate, including a primer and a top coat;

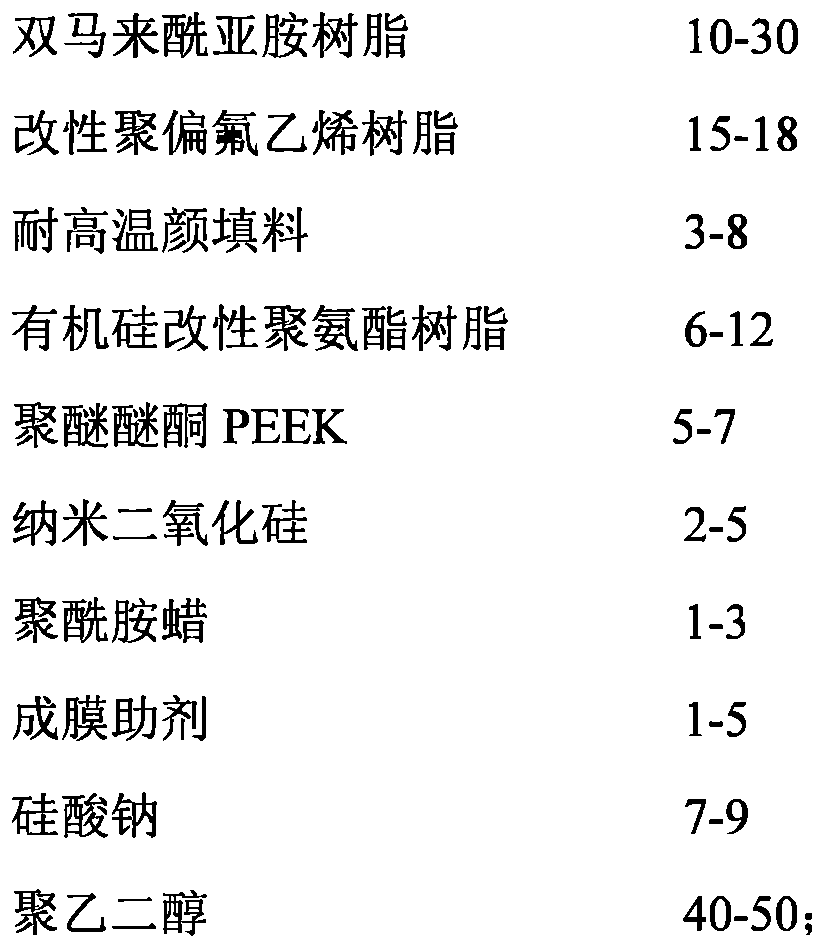

[0026] Described primer is made up of the raw material of following parts by weight:

[0027]

[0028] The preparation method of the primer comprises the following steps: (1) mixing polyethylene glycol, bismaleimide resin, polyether ether ketone PEEK, high temperature resistant pigments and fillers, nano silicon dioxide, polyamide wax and film-forming aids are ground in a sand mill to a fineness below 15 microns to obtain a pre-dispersion; (2) under low-speed stirring, the modified polyvinylidene fluoride resin, organosilicon-modified polyurethane resin and silicon Add sodium bicarbonate to the above-mentioned pre-dispersion, and continue to stir for 10 minutes; the effect of the primer in the two-layer system includes adhesion to the substrate, interlayer bonding with the surface layer, anti-corrosion, anti-steam penetration and improvement. ...

Embodiment 2

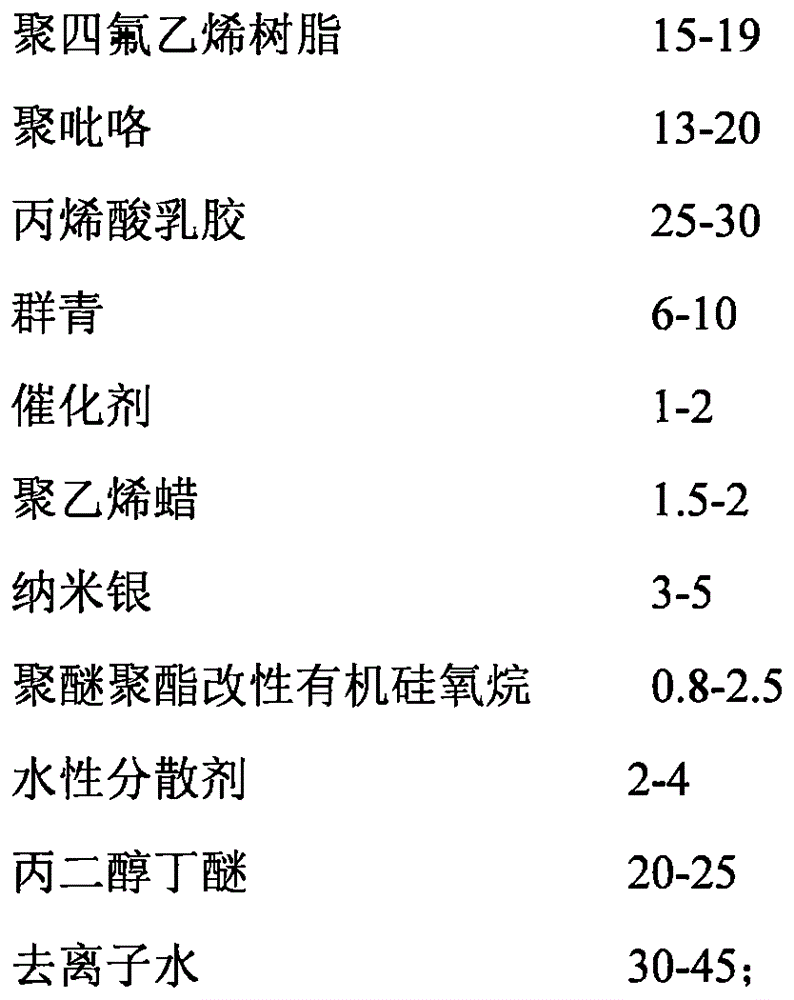

[0034] An application of a wear-resistant and antibacterial non-stick pan coating in the preparation of a microwave oven, including a primer coating and a surface coating;

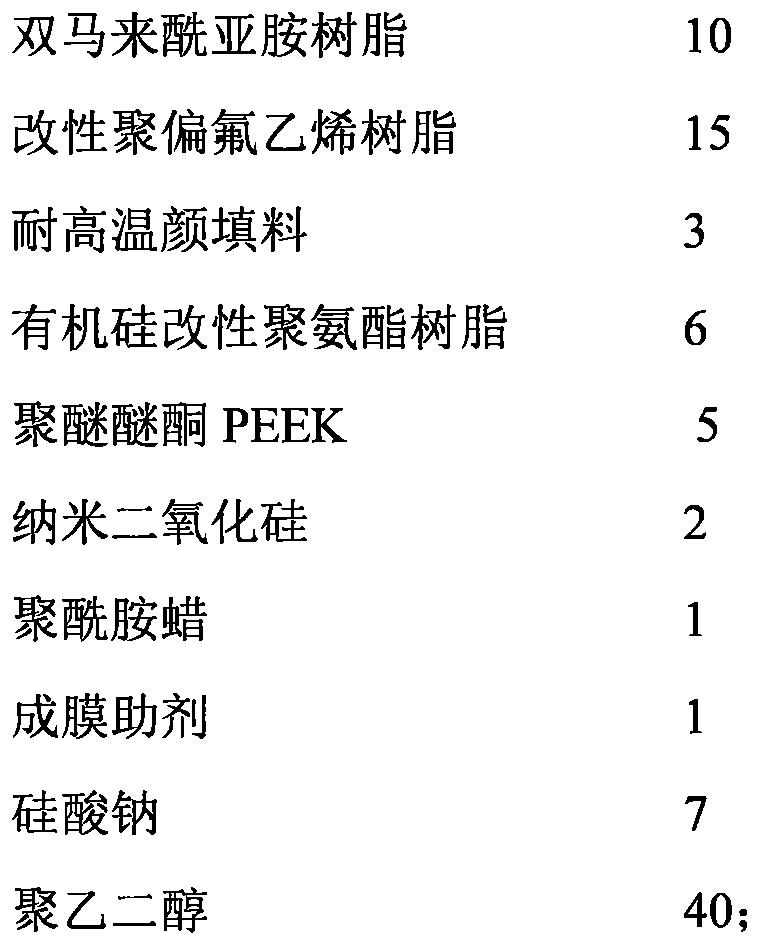

[0035] Described primer is made up of the raw material of following parts by weight:

[0036]

[0037] The preparation method of the primer comprises the following steps: (1) mixing polyethylene glycol, bismaleimide resin, polyether ether ketone PEEK, high temperature resistant pigments and fillers, nano silicon dioxide, polyamide wax and film-forming aids are ground in a sand mill to a fineness below 15 microns to obtain a pre-dispersion; (2) under low-speed stirring, the modified polyvinylidene fluoride resin, organosilicon-modified polyurethane resin and silicon Add sodium bicarbonate to the above-mentioned pre-dispersion, and continue to stir for 10 minutes; the effect of the primer in the two-layer system includes adhesion to the substrate, interlayer bonding with the surface layer, anti-corrosion,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com