Renewable amino-functionalized magnetic carbon nanocomposite material and its preparation method and application

A nanocomposite material, amino functionalization technology, applied in chemical instruments and methods, alkali metal compounds, inorganic chemistry, etc., can solve the application research of renewable amino functionalized magnetic carbon nanocomposite materials, which has not been reported in the literature and is not easy to achieve. Solid-liquid separation and reuse, difficult to achieve solid-liquid separation and other problems, to achieve the effect of rapid separation and enrichment, strong magnetic, strong removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: One-pot preparation of renewable amino functionalized magnetic carbon nanocomposite

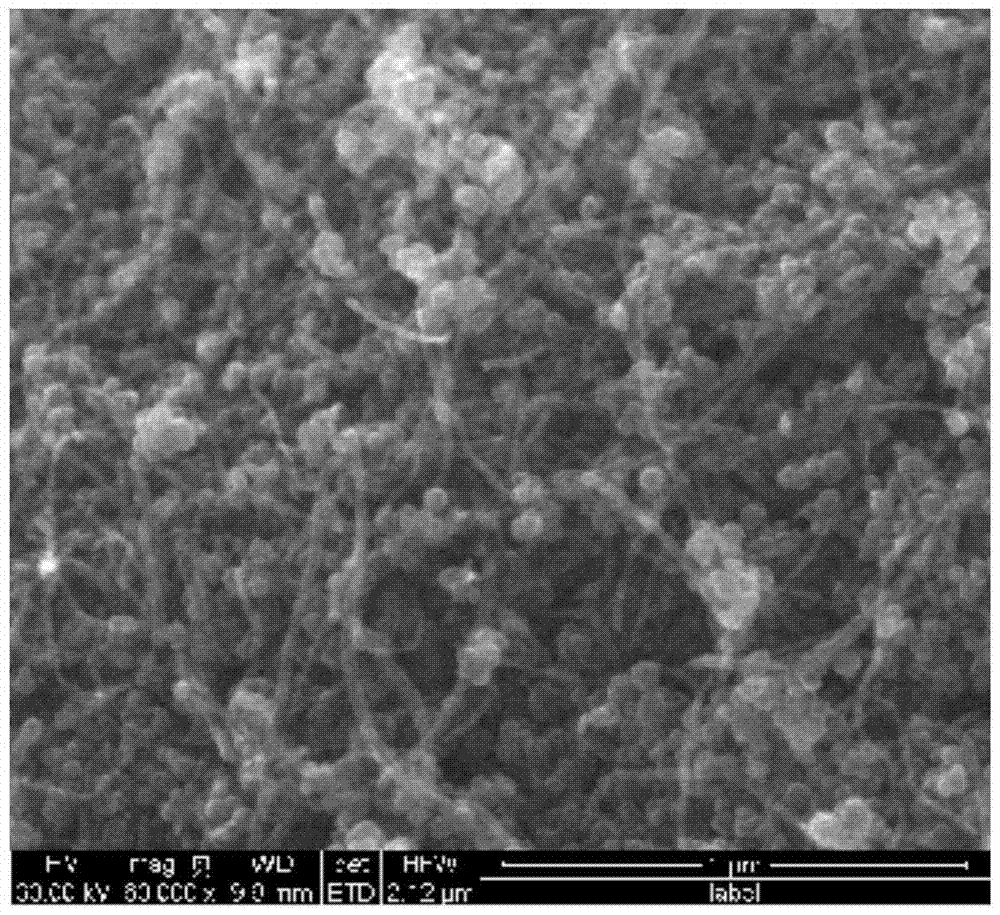

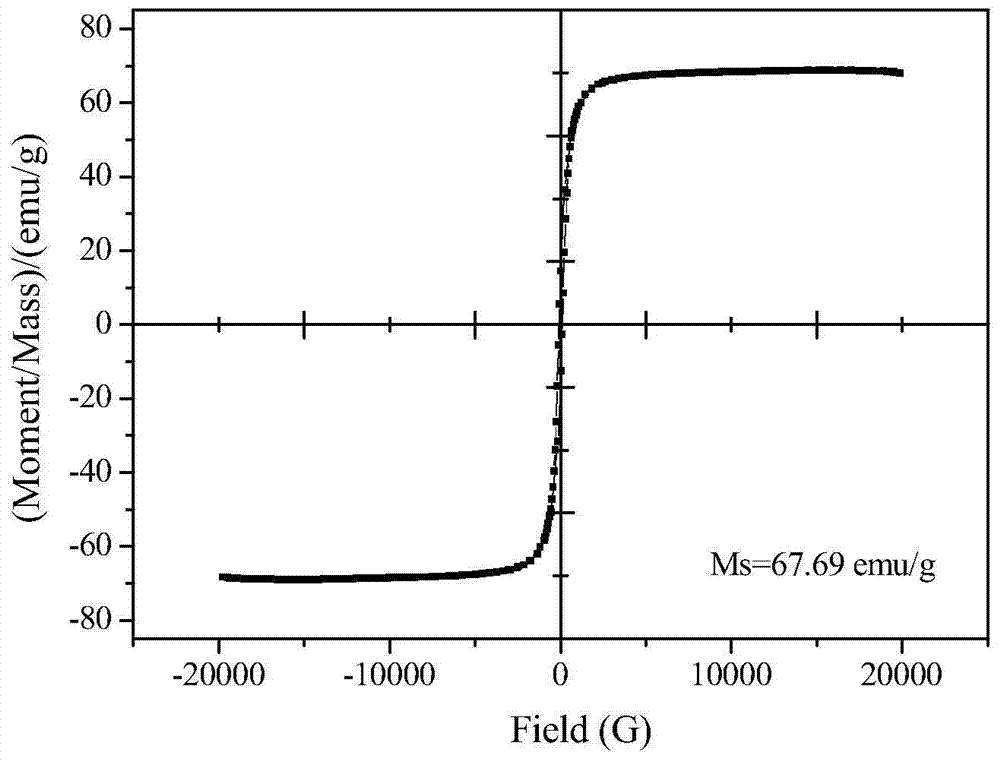

[0041] 5.0g FeCl 3 ·6H 2 O was added to 30mL of ethylene glycol, and ultrasonically dispersed for 0.5h until the solution was clear; then added 3.0g of anhydrous sodium acetate, then 0.6g of sodium hydroxide and 5.0mL of ethylenediamine, ultrasonically dispersed for 0.5h, and added 20mg of carbon nanotubes , Ultrasonic dispersion at 50°C for 1h, and then the mixed solution was added to the polytetrafluoroethylene autoclave and reacted at 200°C for 8h. After cooling to room temperature, magnetic separation, washing with ultrapure water 3 times to pH 7.0, washing with ethanol several times, and vacuum drying at 60°C for 6 hours, a renewable amino-functional magnetic carbon nanocomposite was prepared. The scanning electron micrograph of the prepared renewable amino-functionalized magnetic carbon nanocomposite is as follows figure 1 As shown, Fe in the renewable amino-functionalize...

Embodiment 2

[0042] Example 2: One-pot preparation of renewable amino-functionalized magnetic carbon nanocomposites

[0043] 4.8g Fe 2 (SO 4 ) 3 ·7H 2 O was added to 35mL of ethylene glycol, and ultrasonically dispersed for 0.5h until the solution was clear; then added 5.0g of anhydrous sodium acetate, then 1.0g of sodium hydroxide and 25.0mL of ethylenediamine, ultrasonically dispersed for 0.5h, and added 100mg of carbon nanotubes , Ultrasonic dispersion at 50°C for 0.5h, and then the mixed solution was added to the polytetrafluoroethylene autoclave and reacted at 200°C for 10h. After cooling to room temperature, magnetic separation, washing with ultrapure water several times to pH 7.0, washing with ethanol 4 times, and vacuum drying at 90°C for 12 hours, a renewable amino-functionalized magnetic carbon nanocomposite was prepared.

Embodiment 3

[0044] Example 3: One-pot preparation of renewable amino-functionalized magnetic carbon nanocomposites

[0045] 1.0g FeCl 3 ·6H 2 O was added to 20mL of ethylene glycol, and ultrasonically dispersed for 0.5h until the solution was clear; then added 1.0g of anhydrous sodium acetate, then 0.2g of sodium hydroxide and 15.0mL of diethylenetriamine, ultrasonically dispersed for 0.3h, and added 80mg of carbon nano Tube, ultrasonic dispersion at 50°C for 0.3h, then the mixed solution was added to the polytetrafluoroethylene autoclave and reacted at 200°C for 4h. After cooling to room temperature, magnetic separation, washing with ultrapure water several times to pH 7.0, washing with ethanol 5 times, and vacuum drying at 30°C for 10 hours, a renewable amino functionalized magnetic carbon nanocomposite was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com