A kind of ultraviolet curing silicone release agent and preparation method thereof

An ultraviolet light, silicone technology, applied in the direction of biocide-containing paints, coatings, antifouling/underwater coatings, etc., can solve problems such as product denaturation, and achieve low peel force, low curing temperature, and substrate adaptability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

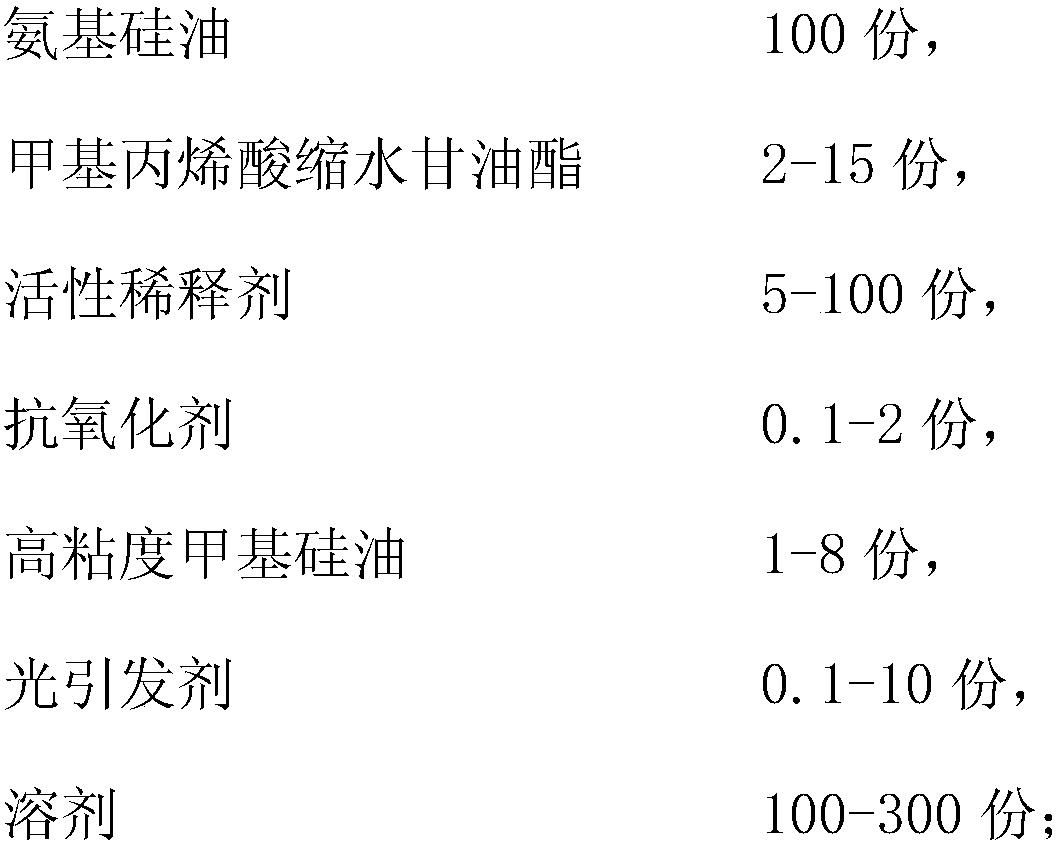

[0031] A UV-curable silicone release agent, made of the following raw materials in parts by weight: 100 parts of amino silicone oil (ammonia value 0.7-1, kinematic viscosity: 150000 mPa·s), 10 parts of glycidyl methacrylate, hexyl 10 parts of diol diacrylate, 0.2 parts of hydroquinone, 5 parts of 1,000,000 CTS high-viscosity methyl silicone oil, 3 parts of 1-hydroxycyclohexyl phenyl ketone, 150 parts of No. 92 gasoline.

[0032] A kind of preparation method of ultraviolet curing silicone release agent is as follows:

[0033] Put 100 parts of amino silicone oil, 10 parts of glycidyl methacrylate, 0.2 parts of hydroquinone, and 150 parts of No. 92 gasoline into the mixing kettle, stir overnight at room temperature, and then add 10 parts of hexanediol diacrylate under stirring conditions , 5 parts of 1000000CTS high-viscosity methyl silicone oil, 3 parts of 1-hydroxycyclohexyl phenyl ketone, stirred and mixed evenly to obtain a UV-curable silicone release agent of the present inv...

Embodiment 2

[0037] A UV-curable silicone release agent, made of the following raw materials in parts by weight: 100 parts of amino silicone oil (ammonia value 0.6-0.8, kinematic viscosity: 10000 mPa·s), 5 parts of glycidyl methacrylate, two 20 parts of tripropylene glycol diacrylate, 0.1 part of tert-butyl hydroquinone, 10 parts of 500000 CTS high viscosity methyl silicone oil, 2 parts of 2-hydroxy-2-methyl-1-phenyl-1-acetone, 92 No. gasoline 100 parts.

[0038] A kind of preparation method of ultraviolet curing silicone release agent is as follows:

[0039] Put 100 parts of amino silicone oil, 5 parts of glycidyl methacrylate, 0.1 part of tert-butyl p-phenol, and 100 parts of No. 92 gasoline into the mixing kettle, and stir overnight at room temperature. Then add tripropylene glycol diacrylate under stirring condition 20 parts, 10 parts of 500000 CTS high-viscosity methyl silicone oil, 2 parts of 2-hydroxy-2-methyl-1-phenyl-1-acetone, stir and mix evenly to obtain a UV-curable silicone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com