A kind of citric acid-polyacrylate magnetic hydrogel, its preparation method and application

A technology of polyacrylate and citric acid, applied in chemical instruments and methods, and other chemical processes, to achieve the effects of increasing adsorption capacity, reducing acidification, and facilitating recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0026] A kind of citric acid-polyacrylate magnetic hydrogel, its preparation method is as follows:

[0027] According to the raw material ratio in Table 1, weigh acrylic acid (AA) in a 100ml beaker, add 30% NaOH solution dropwise to the acrylic acid under stirring, after the two react, add acrylamide (AM), and mix well, Add cross-linking agent N,N-methylenebisacrylamide (MBA), ultrasonically shake to mix evenly, add magnetic Fe 3 o 4 Particles, ultrasonic vibration to fully dissolve, add citric acid, ultrasonic vibration to dissolve, then add 0.05mol / L ammonium persulfate solution, add 0.05mol / L sodium sulfite solution within 20~30s, mix well, put in 70℃ water bath heated and stirred until solidified, and then dried in an oven at 60°C to obtain the citric acid-polyacrylate magnetic hydrogel.

[0028] The formula of citric acid-polyacrylate magnetic hydrogel in table 1 embodiment 1~5

[0029]

[0030] Among them, the magnetic Fe 3 o 4 Particles were prepared by partial ...

Embodiment 6

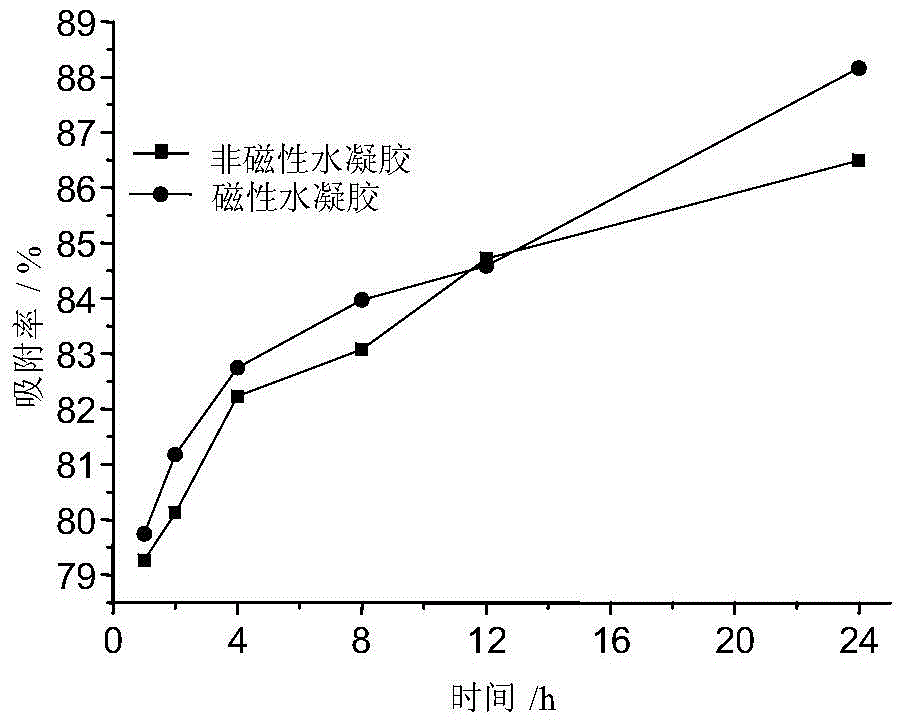

[0032] Example 6: Comparison of the adsorption properties of citric acid-polyacrylate magnetic hydrogel and citric acid-polyacrylate non-magnetic hydrogel

[0033] Dissolve 0.2g of BCO in 100mL of absolute ethanol, add 100mL of H 2 O Prepare a BCO solution with a mass concentration of 0.1%; dissolve 5.4 g of ammonium chloride in water, add 35 mL of ammonia water, and dilute to 100 mL to obtain an ammonium chloride-ammonia water buffer solution, adjust the pH value to 8.5 for later use.

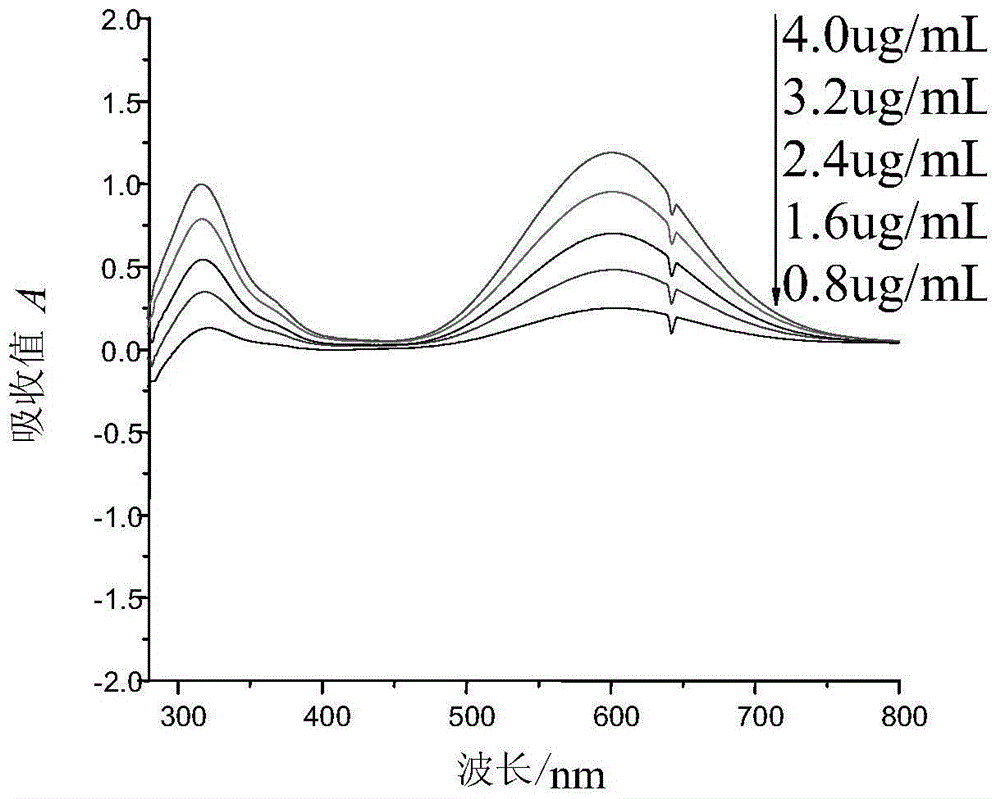

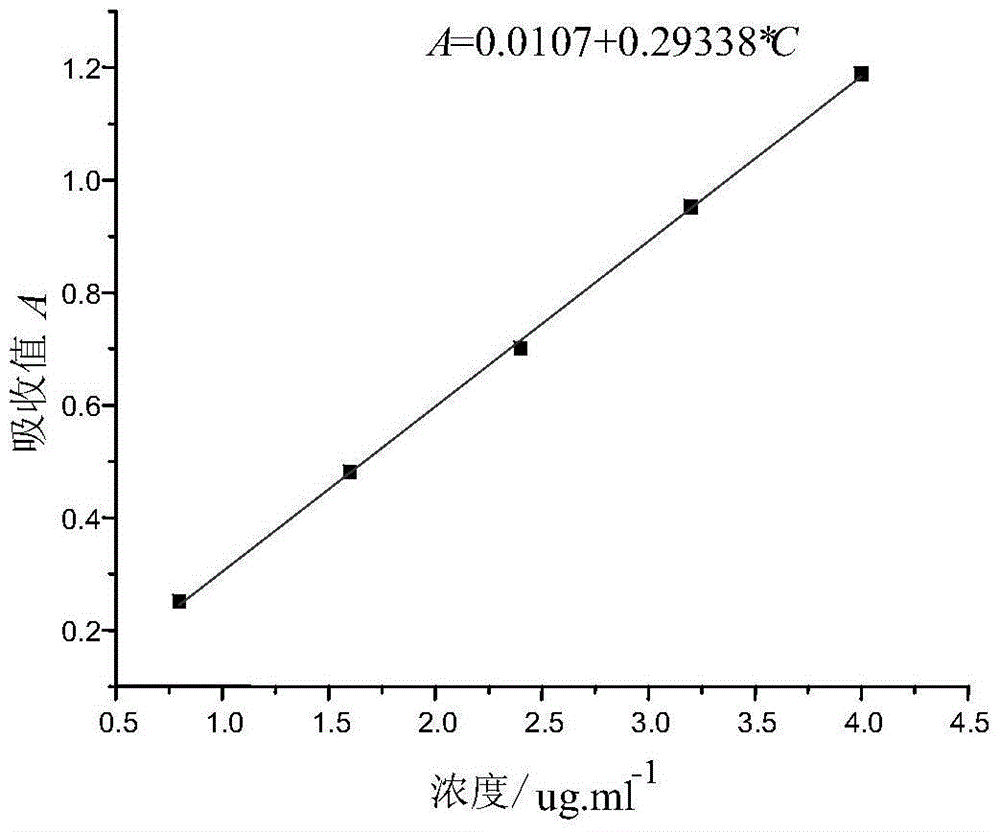

[0034] In a 25mL colorimetric tube, add 0mL (reference), 2mL, 4mL, 6mL, 8mL, 10mL of 10.0mg / L Cu2+ Standard solution, then add 5mL of pH=8.5 ammonium chloride-ammonia buffer solution and 5mL of 1g / L BCO color developer respectively, add deionized water to make up to the mark, and shake well. After full color development for 1 h, Cu was measured by UV spectrophotometer. 2+ UV absorption spectrum such as figure 1 , absorbance vs. Cu 2+ The linear relationship of concentration C is as follows ...

Embodiment 7

[0038] Embodiment 7: the water absorption rate of the citric acid-polyacrylate magnetic hydrogel of embodiment 1~5

[0039] Accurately weigh 0.2 g of the citric acid-polyacrylate magnetic hydrogels of Examples 1 to 5, soak them in sufficient deionized water at room temperature, take them out every 1 hour, drain off the surface water, weigh and record the data . After recording, soak in deionized water again until the adsorption is saturated.

[0040] Experimental results such as Figure 4 As shown, after 9 hours of adsorption, the weight remained basically unchanged, indicating that the citric acid-polyacrylate magnetic hydrogel had been adsorbed and saturated. The water absorption rates of the citric acid-polyacrylate magnetic hydrogels of Examples 1 to 5 are respectively: 111.11, 114.79, 132.16, 22.16, and 16.37, and the water absorption rates of the citric acid-polyacrylate magnetic hydrogels of Example 3 are the highest. The citric acid-polyacrylate magnetic hydrogel of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com