Platable MPI (polyimide film with maleimide side groups) modified engineering plastic alloy and preparation method thereof

An engineering plastic alloy and modification technology, which is applied in the field of engineering plastic alloy, can solve the problems of not being able to meet the production and processing of fenders, cannot be electroplated, and the size is unstable, and achieve excellent electrical and mechanical properties, convenient operation and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

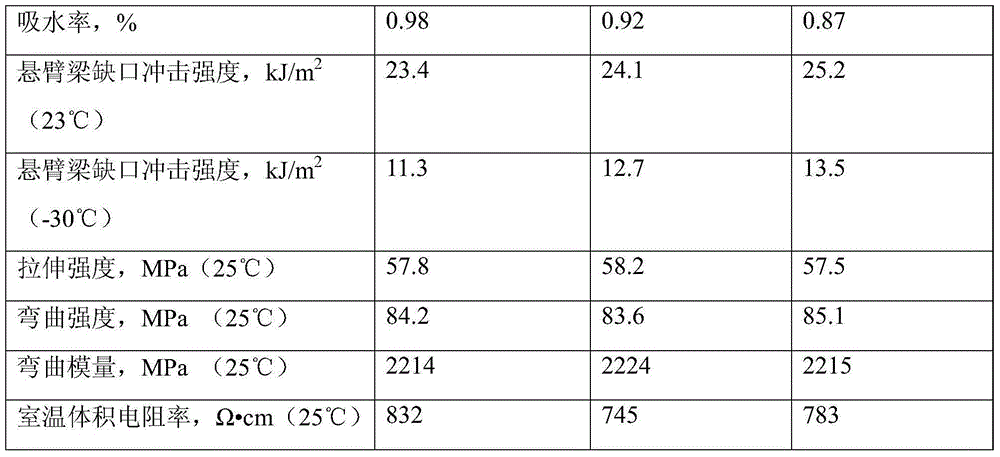

Examples

Embodiment 1

[0043] Add 44.0 grams (0.1 moles) of 2,2-bis[4-(2,4-diaminophenoxy)phenyl]propane and 1645 grams of N-methyl-2-pyrrolidone into the reaction kettle, stir and dissolve at room temperature Afterwards, cool in an ice-water bath to below 5°C, add 19.6 grams (0.2 moles) of maleic anhydride, 193.3 grams (0.6 moles) of 3,3',4,4'-tetracarboxybenzophenone dianhydride and 31.0 grams (0.1 mol) 3,3',4,4'-tetracarboxydiphenyl ether dianhydride, after stirring for 1 hour, add 259.2 grams (0.5 mol) of 2,2-bis[4-(4-aminophenoxy)benzene Base] hexafluoropropane, continue to stir and react for 4 hours, then add 183.6 grams (1.8 moles) of acetic anhydride and 0.65 grams (0.007 moles) of picoline, remove the ice-water bath, heat up to 100 ° C, stir and react for 4 hours, add 3000 grams of ethanol and 290 grams of methanol were stirred rapidly for 1 hour, filtered, washed 2-3 times with 830 grams of acetone, and vacuum-dried at 90° C. for 3 hours to obtain 518.8 grams of MPI resin (theoretical yiel...

Embodiment 2

[0045]Add 44.0 grams (0.1 moles) of 2,2-bis[4-(2,4-diaminophenoxy)phenyl]propane and 4480 grams of N,N-dimethylformamide into the reaction kettle and stir at room temperature After dissolving, cool in an ice-water bath to below 5°C, add 19.6 grams (0.2 moles) of maleic anhydride, 624.0 grams (1.2 moles) of 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl] Propane dianhydride, after stirring and reacting for 2 hours, add 180.0 grams (0.9 moles) of 3,4'-diaminodiphenyl ether and 29.2 grams (0.1 moles) of 1,3-bis(4-aminophenoxy)benzene, continue Stir the reaction for 2.5 hours, then add 428.4 grams (4.2 moles) of acetic anhydride and 9.48 grams (0.12 moles) of pyridine, remove the ice-water bath, heat up to 90 ° C, stir and react for 8 hours, add 22400 grams of ethanol, and stir rapidly for 1 hour. Filter, wash 2-3 times with 4480 g of acetone, and dry in vacuum at 90° C. for 5 hours to obtain 851.0 g of MPI resin (theoretical yield is 853.6 g), denoted as MPI-2, with a yield of 99.7%.

Embodiment 3

[0047] Put 400 grams of 1% 3-aminopropyltriethoxysilane aqueous solution, 70.0 grams of copper powder and 30.0 grams of silver powder into the reaction kettle, stir at 60°C for 1 hour, cool to room temperature, and filter , dried at 100° C. for 1 hour to obtain 100.0 g of coupling agent-treated conductive filler, which is designated as ECF-1.

[0048] Put 400 grams of 3-aminopropyltriethoxysilane aqueous solution, 50.0 grams of silver-plated copper powder and 50.0 grams of aluminum powder into the reaction kettle with a concentration of 3% by mass, and stir at 80°C for 2 hours, then cool to Filter at room temperature and dry at 100° C. for 2 hours to obtain 100.0 g of coupling agent-treated conductive filler, which is designated as ECF-2.

[0049] Put 800 grams of 5% glycidoxypropyltriethoxysilane aqueous solution, 20.0 grams of graphene powder and 80.0 grams of silver-plated copper powder into the reactor, and stir at 70 ° C for 2 hours , cooled to room temperature, filtered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com