Strain for highly producing acid-resistant high-temperature alpha-amylase and liquid fermentation method of strain

A technology of liquid fermentation and amylase, which is applied in the field of bioengineering, can solve the problems of poor thermal stability and narrow pH range, and achieve the effect of stable acid resistance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The breeding of embodiment 1 bacterial strain

[0027] 1. Preparation of Bacterial Suspension

[0028] Draw 10 mL of Bacillus licheniformis B307 seed liquid into a centrifuge tube, centrifuge at 8000 rpm for 5 min, discard the supernatant, and wash the bacteria with 10 mL of normal saline. Centrifuge twice under the same conditions, and resuspend the precipitated bacteria with 2 mL of sterile water to obtain a bacterial suspension. The concentration of the bacterial suspension is 10 7 individual / mL.

[0029] 2. Atmospheric room temperature plasma mutagenesis

[0030] Pipette 10 μL of bacterial suspension onto the slide, place the slide on the rotary table in the operating room of the normal-pressure room temperature plasma system with tweezers, and slowly adjust the knob of the lifting platform (refer to the scale of the lifting platform) to make the distance between the slide and the generator about 2mm. Mutagenesis irradiation time selection 30s, 35s, 40s. After t...

Embodiment 2

[0034] Embodiment 2 liquid fermentation produces acid-resistant high-temperature α-amylase

[0035] Slant culture: take an inoculation loop of the Bacillus licheniformis mutant strain M6-X3 and inoculate it on a solid slope of LB, and culture at a constant temperature of 34° C. for 36 hours.

[0036] Shake flask culture: take an inoculation loop slant seed lawn, insert it into LB liquid medium, and cultivate it for 10 hours under the conditions of initial pH 6.6, 36°C, and shaker speed 250rpm.

[0037] Seed tank culture: the seed solution cultivated in shake flasks was transferred into the seed tank according to 4% of the inoculum amount, and cultivated for 13 hours under the conditions of initial pH 6.3, fermentation temperature 34°C, and rotation speed 250 rpm.

[0038] The formula of the seed tank culture medium is: 3% maltodextrin, 0.2% yeast powder, 0.25% calcium chloride, 0.8% ammonium sulfate, 0.5% peptone, 0.5% disodium hydrogen phosphate, pH6.3.

[0039] Fermentation...

Embodiment 3

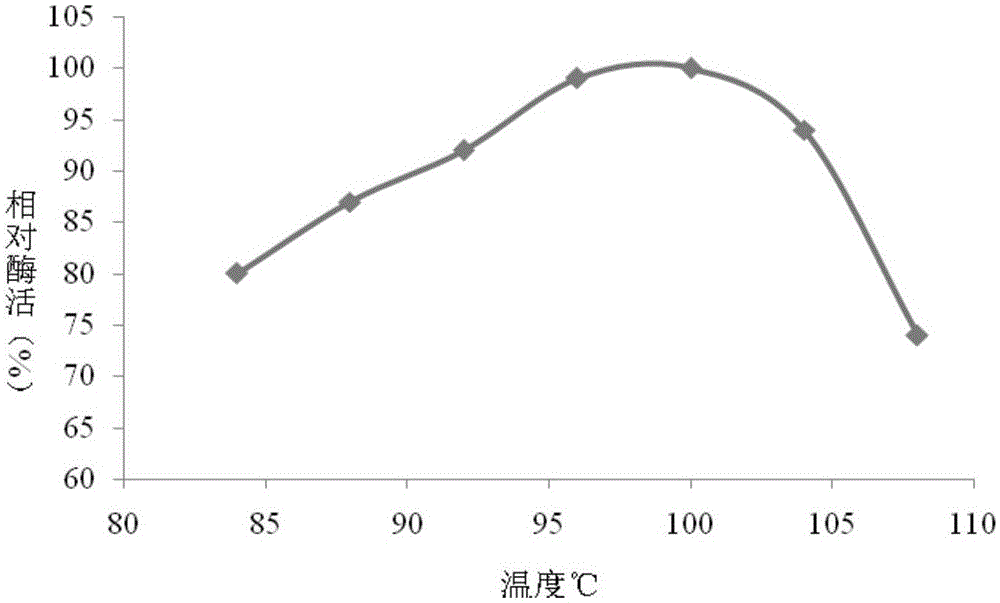

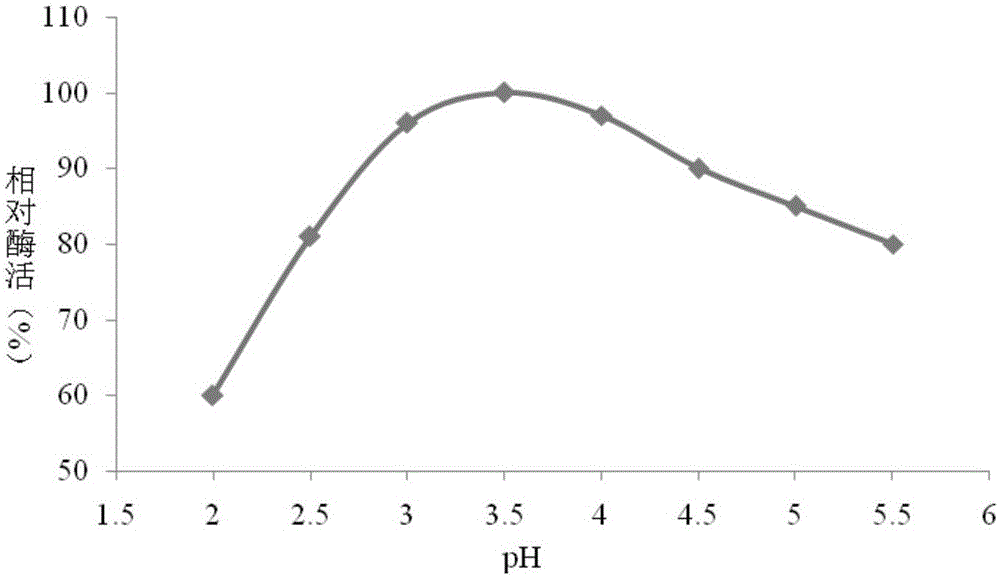

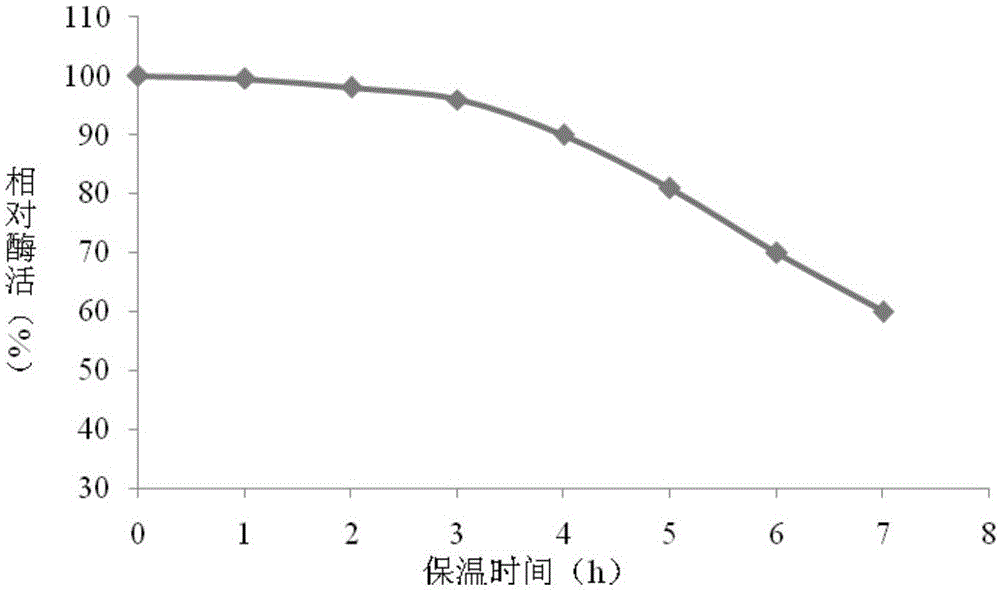

[0044] The basic properties of the acid-resistant high-temperature α-amylase produced by embodiment 3

[0045] Based on the acid-resistant high-temperature α-amylase with an enzyme activity of 41518u / mL, the enzyme activity assay experiments were carried out at different temperatures and different pHs. The optimum reaction temperature of the enzyme produced by this strain is 96-100°C, and the optimum pH The range is 4.0-5.0. Incubate at 95°C for 3 hours, and the remaining enzyme activity is 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com