Method for preparing lipidosome

A liposome and lecithin technology, which is applied to skin care preparations, pharmaceutical formulations, cosmetic preparations and other directions, can solve problems such as skin damage and organic substance residues, and achieves stable liposome system, simple and safe preparation process The effect of non-toxic particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

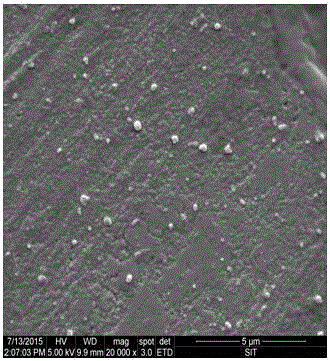

Image

Examples

Embodiment 1

[0059] A liposome, calculated by weight percentage, the composition and content of each raw material are as follows:

[0060] Lecithin 1.0%

[0061] Polyol 1.0%

[0062] Surfactant 0.1%

[0063] Inorganic salt 0.01%

[0064] Water 97.89%

[0065] The lecithin is soybean lecithin with a PC (phosphatidylcholine) content of 25%, an industrial-grade product produced by Beijing Meiyasi Phospholipid Technology Co., Ltd.;

[0066] Described polyhydric alcohol is 1,2-propanediol, the analytical grade product that Sinopharm Chemical Reagent Co., Ltd. produces;

[0067] The surfactant is polyoxyethylene sorbitan laurate, a chemical grade product produced by Sinopharm Chemical Reagent Co., Ltd.;

[0068] The inorganic salt is magnesium sulfate, an analytical-grade product produced by Sinopharm Chemical Reagent Co., Ltd.

[0069] The preparation method of above-mentioned a kind of liposome specifically comprises the following steps:

[0070] (1) Dissolving lecithin in polyol at 20-...

Embodiment 2

[0076] A liposome, calculated by weight percentage, the composition and content of each raw material are as follows:

[0077] Lecithin 10.0%

[0078] Polyol 7.5%

[0079] Surfactant 2.5%

[0080] Inorganic salt 1.0%

[0081] Water 79.0%

[0082] Described lecithin is the soybean lecithin of PC content 50%, the industrial grade product that Beijing Meiyasi Phospholipid Technology Co., Ltd. produces;

[0083] Described polyhydric alcohol is 1,3-butanediol, the analytical grade product that Sinopharm Chemical Reagent Co., Ltd. produces;

[0084] The surfactant is polyoxyethylene sorbitan stearate, a chemical grade product produced by Sinopharm Chemical Reagent Co., Ltd.;

[0085] The inorganic salt is sodium chloride, an analytical-grade product produced by Sinopharm Chemical Reagent Co., Ltd.

[0086] The preparation method of above-mentioned a kind of liposome specifically comprises the following steps:

[0087] (1) Dissolving lecithin in polyol at 20-80°C to obtain unifor...

Embodiment 3

[0092] A liposome, calculated by weight percentage, the composition and content of each raw material are as follows:

[0093] Lecithin 20.0%

[0094] Polyol 15.0%

[0095] Surfactant 5.0%

[0096] Inorganic salt 2.0%

[0097] Water 58%

[0098] Described lecithin is the egg yolk lecithin of PC content 70%, the industrial grade product that Beijing Meiyasi Phospholipid Technology Co., Ltd. produces;

[0099] The polyhydric alcohol is glycerol, an analytical-grade product produced by Sinopharm Chemical Reagent Co., Ltd.;

[0100] The surfactant is polyoxyethylene sorbitan monooleate, a chemical-grade product produced by Sinopharm Chemical Reagent Co., Ltd.;

[0101] The inorganic salt is sodium citrate, an analytical-grade product produced by Sinopharm Chemical Reagent Co., Ltd.

[0102] The preparation method of above-mentioned a kind of liposome specifically comprises the following steps:

[0103] (1) Dissolving lecithin in polyol at 20-80°C to obtain uniformly disperse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com