Method for preparing keratin/ hydroxyethyl methacrylate(HEMA) composite hydrogel of interpenetrating polymer network structure and application of composite hydrogel

An interpenetrating network structure, methacrylic acid technology, used in the field of composite materials and biomedical materials, can solve the problems of decomposition, poor mechanical properties, low loading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

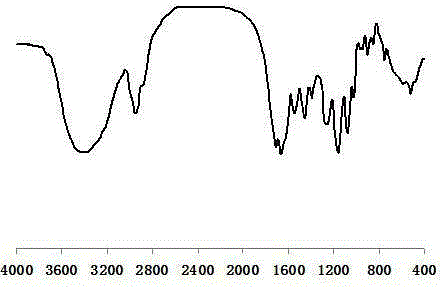

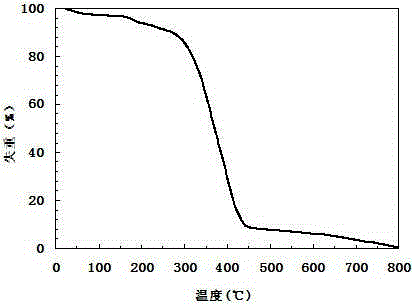

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Under the protection of inert gas, dissolve 0.1g of feather keratin in 5mL of 0.8mol / L urea solution, stir at 50°C for 20min to completely dissolve the keratin; add 10mg of dithiothreitol and stir for 10min; add 1mL of formazan base acrylic- β -Hydroxyethyl ester, stirred for 1h; added 50mg N,N - Methylenebisacrylamide mixed evenly; add 10mg ammonium persulfate, stir for 20min; then add 0.1mL glutaraldehyde and continue stirring for 5min; then let the reaction solution stand at 40°C for 3h; soak and wash with ethanol and water , and dry to obtain a keratin composite hydrogel with an interpenetrating network structure. The composite hydrogel has a cumulative release rate of 72.6% for doxorubicin hydrochloride at body temperature (37°C).

Embodiment 2

[0050] Under the protection of an inert gas, dissolve 0.3g of feather keratin in 8mL of 1mol / L sodium hydroxide solution, stir at 60°C for 25min to completely dissolve the keratin; add 20mg of dithiothreitol and stir for 20min; add 2mL of formazan base acrylic- β -Hydroxyethyl ester, stirred for 2h; added 100mg N,N -Methylenebisacrylamide is mixed evenly, add 15mg ammonium persulfate, stir for 30min, then add 0.3mL glutaraldehyde, continue stirring for 10min; then let the reaction solution stand at 50°C for 5h; After washing and drying, a keratin composite hydrogel with an interpenetrating network structure is obtained. The composite hydrogel has a cumulative release rate of 84.4% for doxorubicin hydrochloride at body temperature (37°C).

Embodiment 3

[0052] Under the protection of inert gas, disperse 0.5g feather keratin in 10mL5mol / L urea, stir at 65°C for 35min to completely dissolve the keratin; add 40mg of mercaptoethanol and stir for 30min; add 3mL of methacrylic acid- β -Hydroxyethyl ester, stirred for 3h; added 100mg N,N - Methylenebisacrylamide is mixed evenly; add 30mg of ammonium persulfate and stir for 30min; then add 0.5mL of glutaraldehyde and continue stirring for 20min; then let the reaction solution stand at 65°C for 6h; After washing and freeze-drying, a keratin composite hydrogel with an interpenetrating network structure is obtained. The composite hydrogel has a cumulative release rate of 90.9% for doxorubicin hydrochloride at body temperature (37°C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com