Nanometer thermite and preparing method thereof

A technology of nano-aluminum and thermite, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of long time, low product energy density, high cost, etc., and achieve the improvement of reaction rate, The effect of convenient post-processing and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

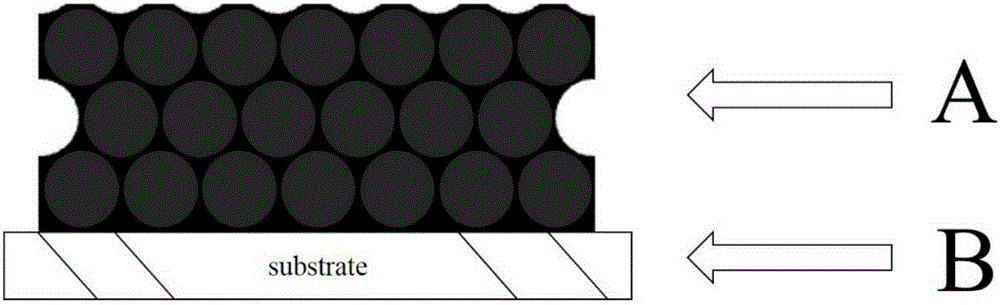

[0038] combine figure 2 , the preparation method of nano thermite of the present invention, comprises the steps:

[0039] Step 1: Prepare PS polymer microspheres, the diameter of the PS polymer microspheres is 20-600nm, and then use deionized water to prepare a PS polymer microsphere dispersion, and the concentration of the PS polymer microsphere dispersion 1~25wt%;

[0040] Step 2: vertically immerse the substrate in the PS polymer microsphere dispersion prepared in step 1, and use the curved liquid surface formed by solvent evaporation to perform directional alignment and self-assembly of PS polymer microspheres to form a colloidal crystal template;

[0041] Step 3: Prepare the nanocomposite metal oxide precursor; including the following two nanocomposite metal oxide precursors, as follows:

[0042] (1) Preparation of nanocomposite metal oxide precursor, wherein the nanocomposite metal oxide is CoFe 2 o 4 , the preparation process of the precursor solution is as follows...

example 1

[0048] Step 1: Prepare PS polymer microspheres with smooth surface, good dispersibility and particle size of 300nm, and then use deionized water to prepare a dispersion of PS polymer microspheres with a concentration of 1.5wt%;

[0049] Step 2: vertically immerse the substrate in the PS polymer microsphere dispersion prepared in step 1, and use the curved liquid surface formed by solvent evaporation to perform directional alignment and self-assembly of PS polymer microspheres to form a colloidal crystal template;

[0050] Step 3: Accurately weigh 24.24gFe(NO 3 ) 3 9H 2 O and 8.73gCo(NO 3 ) 2 ·6H 2 0, then add 20mL methanol and 40mL ethylene glycol, and obtain the nanocomposite metal oxide precursor solution with magnetic stirring for 9h;

[0051] Step 4: Put the PS colloidal crystal template in step 2 into the precursor solution prepared in step 4, take it out after soaking for 3 to 5 minutes, and remove the excess precursor solution, then transfer it to an oven and dry i...

example 2

[0058] Step 1: Prepare PS polymer microspheres with smooth surface, good dispersibility and particle size of 20nm, and then prepare a dispersion of PS polymer microspheres with a concentration of 1.5 wt% with deionized water;

[0059] Step 2: vertically immerse the substrate in the PS polymer microsphere dispersion prepared in step 1, and use the curved liquid surface formed by solvent evaporation to perform directional alignment and self-assembly of PS polymer microspheres to form a colloidal crystal template;

[0060] Step 3: Accurately weigh 24.24gFe(NO 3 ) 3 9H 2 O and 8.73gCo(NO 3 ) 2 ·6H 2 0, then add 20mL methanol and 40mL ethylene glycol, and obtain the nanocomposite metal oxide precursor solution with magnetic stirring for 9h;

[0061] Step 4: Put the PS colloidal crystal template in step 2 into the precursor solution prepared in step 4, take it out after soaking for 3-5 minutes, and remove the excess precursor solution, then transfer it to an oven and dry it at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| heat release | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com