Application of compound hydrate anti-polymeric agent containing rhamnolipid

A rhamnolipid and hydrate technology, which is applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve the problems of hydrate slurry viscosity, limited application, poor biodegradability, etc. Stable polymerization performance, good biodegradability, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment adopts rhamnolipid-containing composite hydrate antipolymerization agent, and applies it to an oil-water system with a water content of 10% (calculated based on the sum of the volumes of water and oil), and the present embodiment The anti-aggregation effect of hydrate anti-aggregation agent was evaluated.

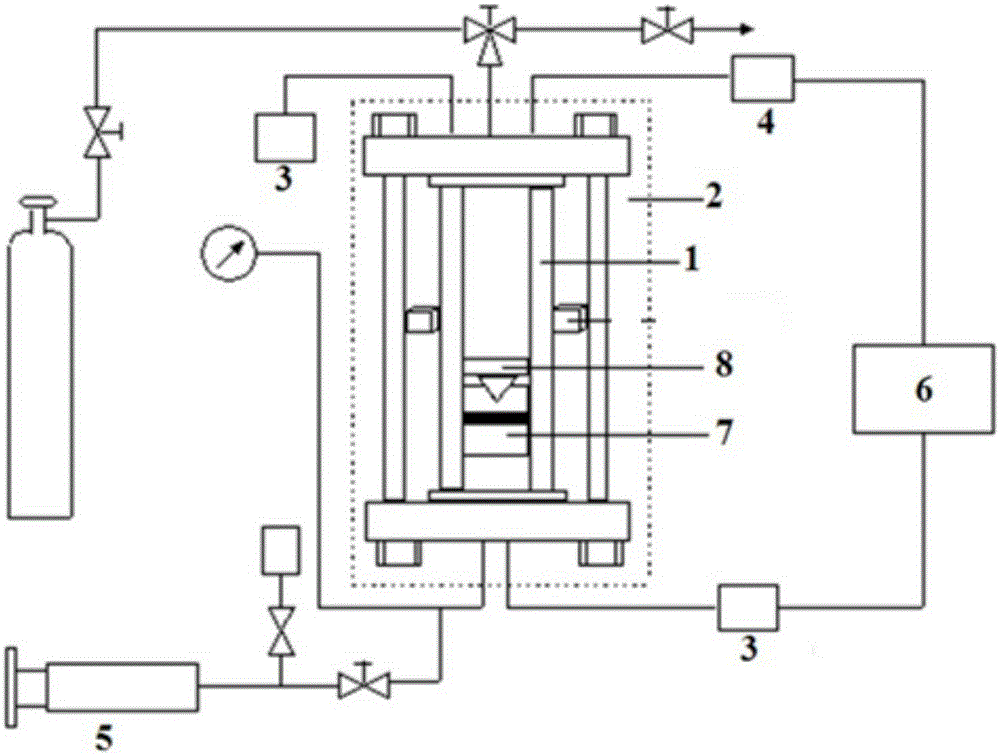

[0032] The present embodiment adopts high-pressure sapphire reactor to carry out system evaluation, such as figure 1 As shown, it mainly includes a high-pressure sapphire reactor body 1, a constant temperature air bath 2, a temperature sensor 3 and a pressure sensor 4, a hand pump 5, a stirring system and an automatic data acquisition system 6. The maximum working volume of high pressure sapphire reactor 1 is 49cm 3 , the maximum working pressure is 50MPa, and the working temperature range is 183K-423K. There is a closed piston 7 in the reaction kettle, which can separate the pressurized fluid (petroleum ether) from the experimental system, and the ...

Embodiment 2

[0045] In this example, rhamnolipid-containing composite hydrate antipolymerization agent is used, which is obtained by mixing rhamnolipid biosurfactant and sodium chloride electrolyte at a mass ratio of 0.5:1.

[0046] In this embodiment, the high-pressure sapphire reactor described in Example 1 is used for evaluation, and the specific experimental process is as described in Example 1.

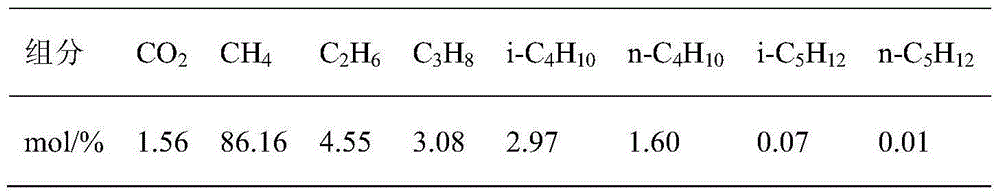

[0047] In this embodiment, the oil-water system in the reactor is composed of 1.5ml deionized water and 13.5ml of -20# diesel oil, that is, the oil-water system with a water content of 10% (based on the sum of the volumes of water and oil), In this embodiment, the added amount of rhamnolipid is 2% of the water amount, the added amount of NaCl is 5% of the water amount, and the experimental gas composition introduced is shown in Table 1.

[0048] During the whole experiment process of this example, the hydrate particles were evenly dispersed in the oil phase, and there was no phenomenon of hyd...

Embodiment 3

[0050] In this example, rhamnolipid-containing composite hydrate antipolymerization agent is used, which is obtained by mixing rhamnolipid biosurfactant and potassium nitrate electrolyte at a mass ratio of 2:1.

[0051] In this embodiment, the high-pressure sapphire reactor described in Example 1 is used for evaluation, and the specific experimental process is as described in Example 1.

[0052] In this embodiment, the oil-water system in the reactor is composed of 1.5ml deionized water and 13.5ml of -20# diesel oil, that is, the oil-water system with a water content of 10% (based on the sum of the volumes of water and oil), In the present embodiment, the added amount of rhamnolipid is 2% of the water amount, KNO 3 The added amount is 5% of the water amount, and the experimental gas composition introduced is shown in Table 1.

[0053] During the whole experiment process of this example, the hydrate particles were evenly dispersed in the oil phase, and there was no phenomenon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com