Preparation method and application of Fe3O4/MIL-101(Cr)

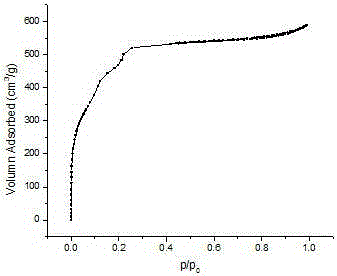

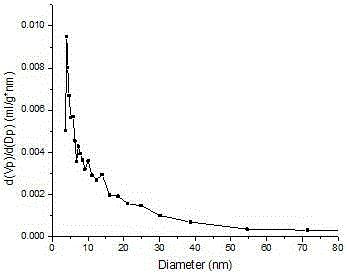

A 3.9H2O, NH3.H2O technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the problem of large particle size of magnetic nanoparticles and reduced surface area of composite materials , Magnetic weakening and other problems, to achieve the effect of stable quality, large surface area and strong magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) MIL-101(Cr) was synthesized by hydrothermal method. Weigh 800mgCr(NO 3 ) 3 9H 2 O and 332mg of terephthalic acid, placed in a polytetrafluoroethylene liner, add 0.4mL of hydrofluoric acid with a mass fraction of 35% and 9.5mL of pure water, ultrasonic for 15min, after mixing evenly, cover and move to a stainless steel reaction kettle After inner sealing, place in an oven at 215° C., react for 9 hours, and then cool down to room temperature naturally. The product is a green powder, which is washed three times with N,N-dimethylformamide, ethanol and pure water respectively, centrifuged at high speed and dried for use.

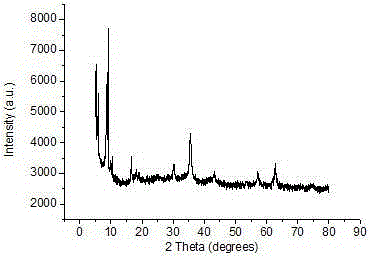

[0032] (2) Preparation of Fe by reduction precipitation method 3 o 4 / MIL-101 (Cr) composite material. Weigh 0.125g of MIL-101(Cr), place it in a 100mL three-necked flask, add 60mL of 0.05mol / L FeCl 3 After the solution was shaken and mixed evenly, it was sonicated at room temperature 25°C for 30 minutes, and then nitrogen gas was passed into th...

Embodiment 2

[0035] (1) MIL-101(Cr) was synthesized by hydrothermal method. Weigh 800mgCr(NO 3 ) 3 9H 2 O and 332mg of terephthalic acid, placed in a polytetrafluoroethylene liner, add 0.4mL of hydrofluoric acid with a mass fraction of 35% and 9.5mL of pure water, ultrasonic for 15min, after mixing evenly, cover and move to a stainless steel reaction kettle After inner sealing, place in an oven at 220° C., react for 8 hours, and then cool to room temperature naturally. The product is a green powder, which is washed three times with N,N-dimethylformamide, ethanol and pure water respectively, centrifuged at high speed and dried for use.

[0036] (2) Preparation of Fe by reduction precipitation method 3 o 4 / MIL-101 (Cr) composite material. Weigh 0.500g MIL-101(Cr), place it in a 100mL three-necked flask, add 30mL FeCl with a concentration of 0.1mol / L 3 After the solution was shaken and mixed evenly, it was sonicated at room temperature 25°C for 30 minutes, then nitrogen gas was passed...

Embodiment 3

[0039] (1) MIL-101(Cr) was synthesized by hydrothermal method. Weigh 800mgCr(NO 3 ) 3 9H 2 O and 332mg of terephthalic acid, placed in a polytetrafluoroethylene liner, add 0.35mL of hydrofluoric acid with a mass fraction of 40% and 9.5mL of pure water, ultrasonic for 15min, after mixing evenly, cover and move to a stainless steel reaction kettle After inner sealing, place in an oven at 225° C., react for 7 hours, and then cool to room temperature naturally. The product is a green powder, which is washed three times with N,N-dimethylformamide, ethanol and pure water respectively, centrifuged at high speed and dried for use.

[0040] (2) Preparation of Fe by reduction precipitation method 3 o 4 / MIL-101 (Cr) composite material. Weigh 1.000g of MIL-101(Cr), place it in a 100mL three-necked flask, add 15mL of 0.2mol / LFeCl 3 After the solution was oscillated and mixed evenly, it was sonicated at room temperature 25°C for 30 minutes, then nitrogen gas was passed into the thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com