Preparation method of cellulose and chitosan hybrid fiber

A technology of chitosan and cellulose, applied in the direction of cellulose/protein conjugated artificial filaments, fiber chemical characteristics, conjugated artificial filaments, etc., can solve uneven pores, uneven mixed fibers, and unstable structural properties and other problems, to achieve the effect of easy operation, excellent performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

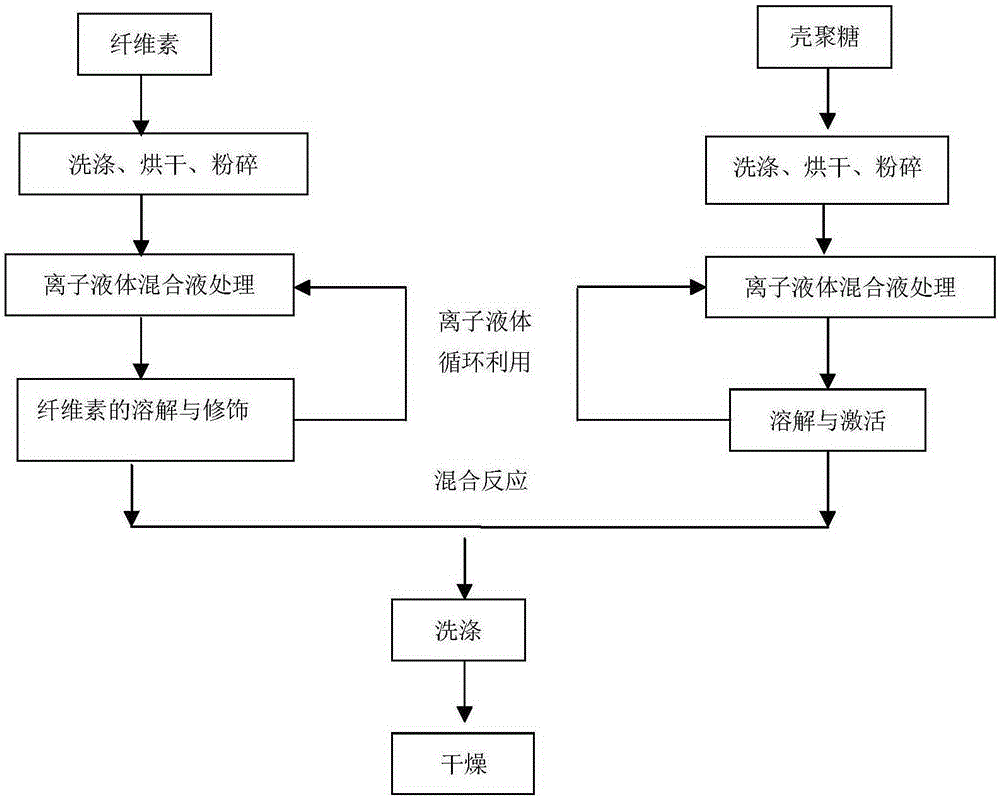

[0024] The invention provides a kind of preparation method of mixed fiber of cellulose and chitosan, its process flow chart is as follows figure 1 shown, including the following steps:

[0025] (1) Wash, dry, and pulverize the cellulose to obtain cellulose powder; mix the cellulose powder with the acidic ionic liquid mixture, keep warm at 30°C to 150°C, add a carboxylation reagent, and stir to complete the dissolution of the cellulose and Modified to obtain product A;

[0026] (2) Get chitosan and acidic ionic liquid mixed solution and mix uniformly, heat treatment, obtain product B, acidic ionic liquid mixed solution is used as solvent and catalyst;

[0027] (3) Mix the products A and B obtained in steps (1) and (2), heat and stir to react evenly, and obtain a sample;

[0028] (4) Add fiber regeneration reagent to the sample obtained in step (3) to wash and remove the liquid preparation in the sample, recover the ionic liquid in the liquid preparation, and dry the solid to ...

Embodiment 1

[0031] Embodiment 1. The preparation method of acidic ionic liquid mixed solution ([AMIM][Cl]-DMSO mixed solution).

[0032] Mix 5g of ionic liquid [AMIM][Cl] and 0.2g of DMSO uniformly, and heat with magnetic stirring at 110°C to obtain.

Embodiment 2

[0033] Embodiment 2. The preparation method of acidic ionic liquid mixed solution ([BmpyM][Cl]-dimethylformamide).

[0034] Mix 4g of ionic liquid [BmpyM][Cl] with 0.2g of dimethylformamide, and heat at 80°C with magnetic stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com