Annular yoke armature winding high-power-density mixed excitation permanent magnet motor

A high power density, permanent magnet motor technology, applied in the shape/style/structure of winding conductors, synchronous machine parts, magnetic circuit static parts, etc., can solve the damage of permanent magnet mechanical structure and the cost of motor power inverter circuit The problems of high cost and high motor cost can eliminate mechanical stress damage, avoid magnetic performance degradation, and save material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

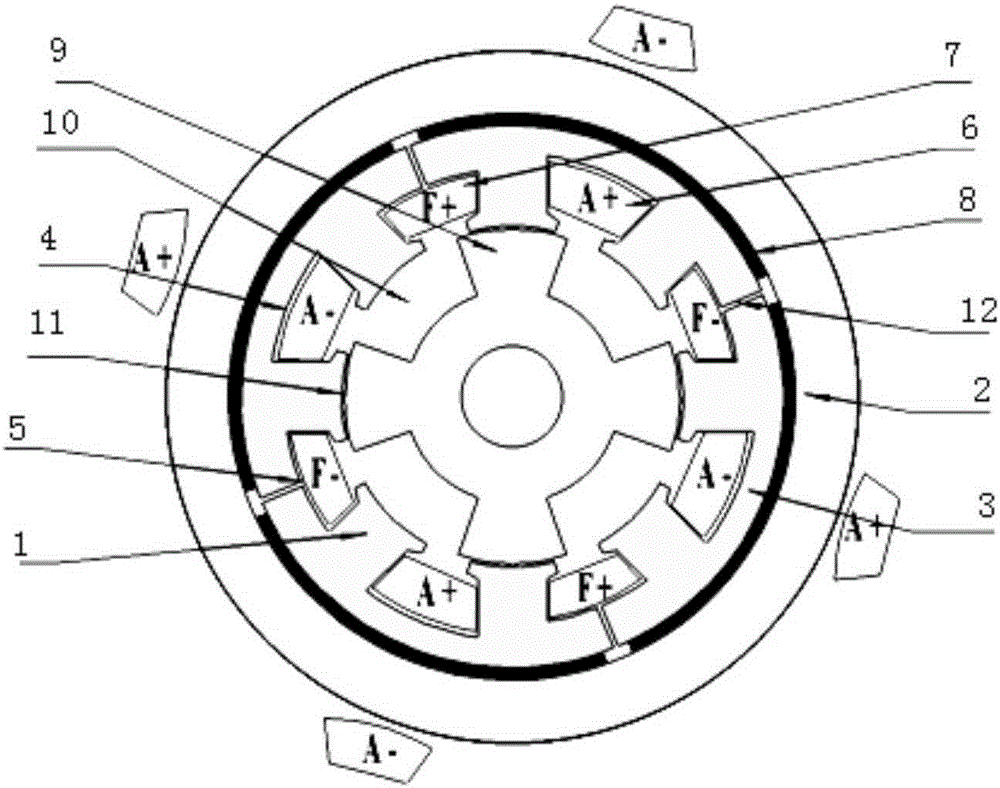

[0068] like image 3 As shown, the number of stator teeth of the motor is 8, the number of rotor teeth is 4, and the number of permanent magnet blocks is 4. This embodiment includes a stator, a rotor, a main air gap and an additional air gap. The stator includes a stator core, a permanent magnet and a stator slot, and the stator The iron core includes stator teeth 1, stator back yoke 2 and stator slot yoke 3. The stator core is made of ferromagnetic material with high magnetic permeability. The stator core is provided with stator slots. The stator slots include armature slots 4 and excitation slots 5. , the armature slots 4 and the excitation slots 5 are alternately arranged at intervals, and the armature winding 6 is placed in the armature slot 4, and the armature winding 6 penetrates from one armature slot 4, and then along the outer surface of the stator back yoke 2 in the direction of the outer diameter Pass out to form a coil, the armature winding 6 is wound around the st...

Embodiment 2

[0070] like Figure 4 As shown, the number of stator teeth of the motor is 8, the number of rotor teeth is 4, and the number of permanent magnet blocks is 16. This embodiment includes a stator, a rotor, a main air gap and an additional air gap. The stator includes a stator core, a permanent magnet and a stator slot, and the stator The iron core includes stator teeth 1, stator back yoke 2 and stator slot yoke 3. The stator core is made of ferromagnetic material with high magnetic permeability. The stator core is provided with stator slots. The stator slots include armature slots 4 and excitation slots 5. , the armature slots 4 and the excitation slots 5 are alternately arranged at intervals, and the armature winding 6 is placed in the armature slot 4, and the armature winding 6 penetrates from one armature slot 4, and then along the outer surface of the stator back yoke 2 in the direction of the outer diameter Pass out to form a coil, the armature winding 6 is wound around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com