Diamond coating layer cutter for composite material machining and preparation method thereof

A technology of diamond coating and composite materials, applied in metal material coating technology, coating, metal processing, etc., can solve problems such as high production costs, inability to fully meet the needs of composite material processing, and limit the scope of use. Low, easy to achieve industrialization, and improve the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

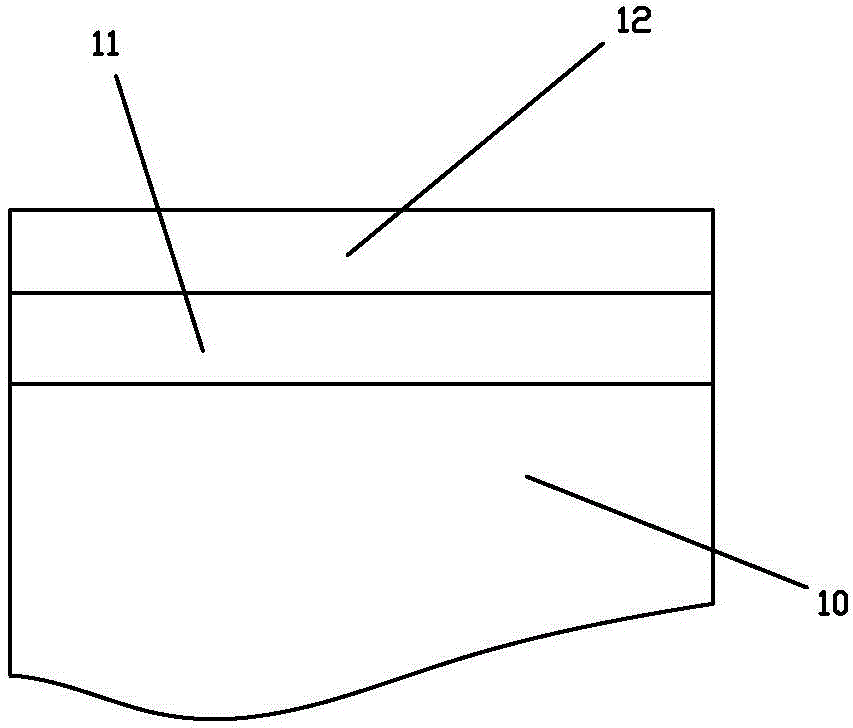

[0033] see figure 1 Shown, a kind of diamond-coated cutting tool for composite material processing of the present invention comprises a substrate 10 and two layers of diamond coatings with hard and wear-resistant features deposited on the substrate by CVD; wherein the diamond coating 11 is The submicrocrystalline diamond coating, the diamond coating 12 is an ultrafine nanocrystalline diamond coating, and the diamond coating on the surface layer is the ultrafine nanocrystalline diamond coating 12 .

[0034] The thickness of the submicrocrystalline diamond coating 11 is 4-5um, and the submicrocrystalline average grain size of the submicrocrystalline diamond coating 11 is 2-3um;

[0035] The thickness of the ultra-fine nanocrystalline diamond coating 12 is 5-6 um, and the average grain size of the ultra-fine nano-crystalline diamond coating 12 is 0.4-0.5 um.

[0036] The coating preparation method of the present embodiment is as follows:

[0037] Select cemented carbide tools d...

Embodiment 2

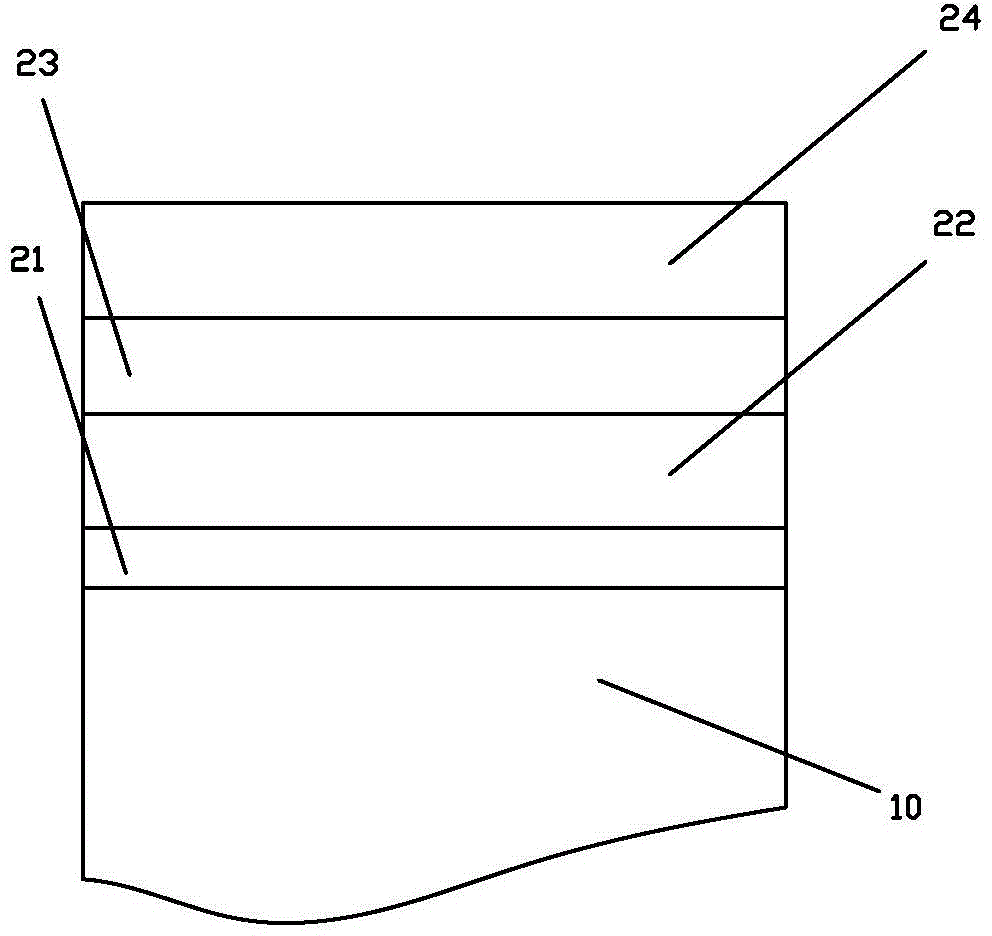

[0039] see figure 2 As shown, a diamond-coated cutting tool for composite material processing of the present invention includes a substrate 10 and four layers of diamond coatings with hard and wear-resistant characteristics deposited on the substrate by CVD; wherein the diamond coating 21 is sub- Microcrystalline diamond coating, diamond coating 22 is an ultrafine nanocrystalline diamond coating, diamond coating 23 is a submicrocrystalline diamond coating, and diamond coating 24 is an ultrafine nanocrystalline diamond coating. The layer is the ultrafine nanocrystalline diamond coating 24 .

[0040]The thickness of the submicrocrystalline diamond coating 21 is 1-2 um, and the average grain size of the sub-microcrystalline diamond coating 21 is 1-2 um;

[0041] The thickness of the ultrafine nanocrystalline diamond coating 22 is 1-2um, and the average grain size of the ultrafine nanocrystalline diamond coating 22 is 0.4-0.5um;

[0042] The thickness of the submicrocrystalline...

Embodiment 3

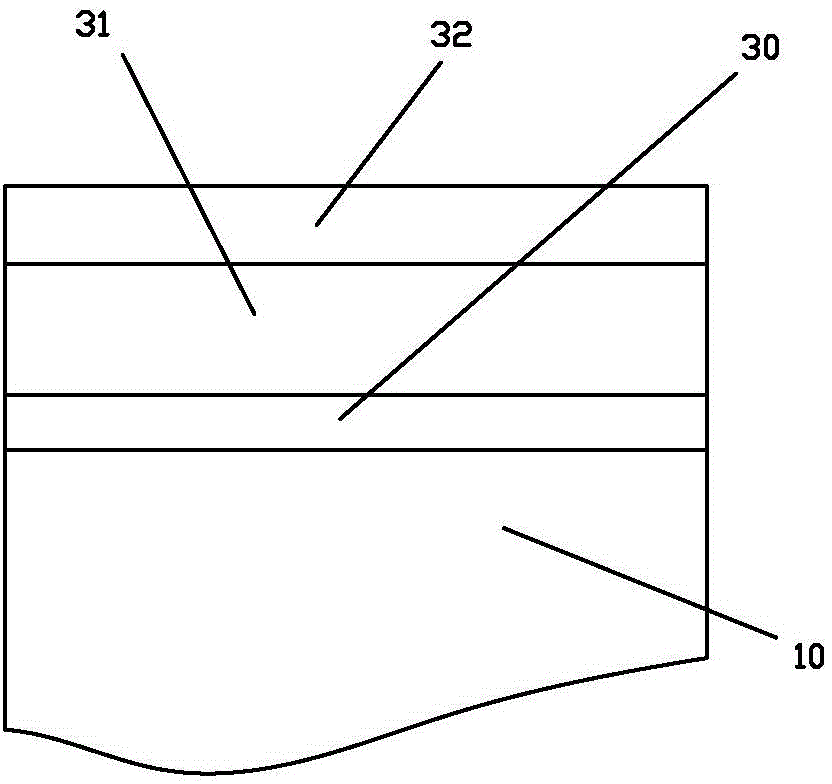

[0047] see image 3 As shown, a diamond-coated cutting tool for composite material processing of the present invention includes a substrate 10 and a two-layer diamond coating with hard and wear-resistant characteristics deposited on the substrate by a CVD method; wherein the diamond coating 31 is sub- Microcrystalline diamond coating, the diamond coating 32 is an ultrafine nanocrystalline diamond coating, and the diamond coating on the surface is the ultrafine nanocrystalline diamond coating 32 .

[0048] The thickness of the submicrocrystalline diamond coating 31 is 7-8um, and the submicrocrystalline average grain size of the submicrocrystalline diamond coating 31 is 2-3um;

[0049] The thickness of the ultrafine nanocrystalline diamond coating 32 is 2-3 um, and the average grain size of the ultrafine nanocrystalline diamond coating 32 is 0.4-0.5 um.

[0050] The coating preparation method of the present embodiment is as follows:

[0051] Select cemented carbide tools dedic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com