Polymeric chemical blocking remover

A plug-removing agent and polymer technology, applied in the field of chemical plug-removing agents, can solve the problems of poor water solubility, unfavorable field application, poor stability, etc., and achieve the effect of good stability, easy storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

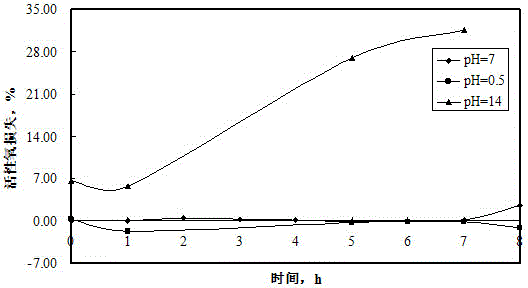

Image

Examples

Embodiment 1

[0031] Take 1.5 parts by mass of urea peroxide, mix with 2.5 parts by mass of formic acid and 2 parts by mass of formaldehyde to obtain a polymer chemical plugging agent product. When used, 84 parts by mass of water were added to make an aqueous solution.

Embodiment 2

[0033] Get 5 parts by mass of urea peroxide and mix with 0.5 parts by mass of formic acid and 5 parts by mass of formaldehyde to obtain a polymer chemical plugging agent product. When used, 96 parts by mass of water was added to make an aqueous solution.

Embodiment 3

[0035] Mix 3 parts by mass of urea peroxide with 1.5 parts by mass of formic acid and 3.5 parts by mass of formaldehyde to obtain a polymer chemical plugging agent product. When used, 90 parts by mass of water was added to make an aqueous solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com