Fishbone fermented milk and preparation method thereof

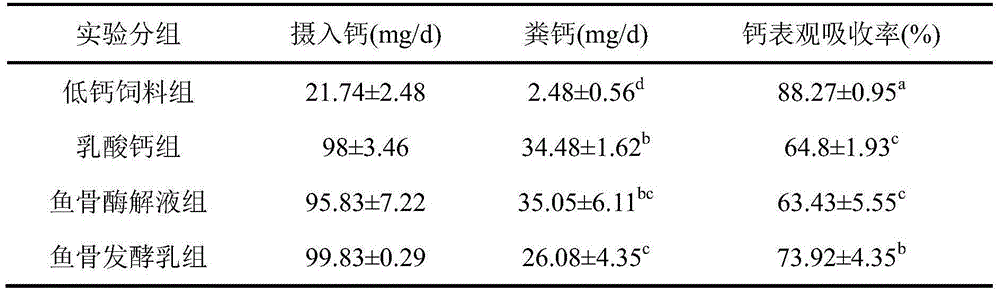

A fermented milk and fish bone technology, applied in dairy products, food preparation, milk preparations, etc., can solve the problems of simple taste, single type, and incomplete nutrition, so as to increase calcium concentration and bone fluid acidity, prevent precipitation, The effect of promoting the absorption of calcium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Softening and homogenization

[0032] After adding the grass carp bone by-products remaining in the processing process to 5 times the volume of the grass carp bone water, it was treated under high pressure at 121°C for 20 minutes to soften the fish bone. Remove the fish meat remaining on the softened fish bones, add 12 times the volume of the fish bones, and then homogenize.

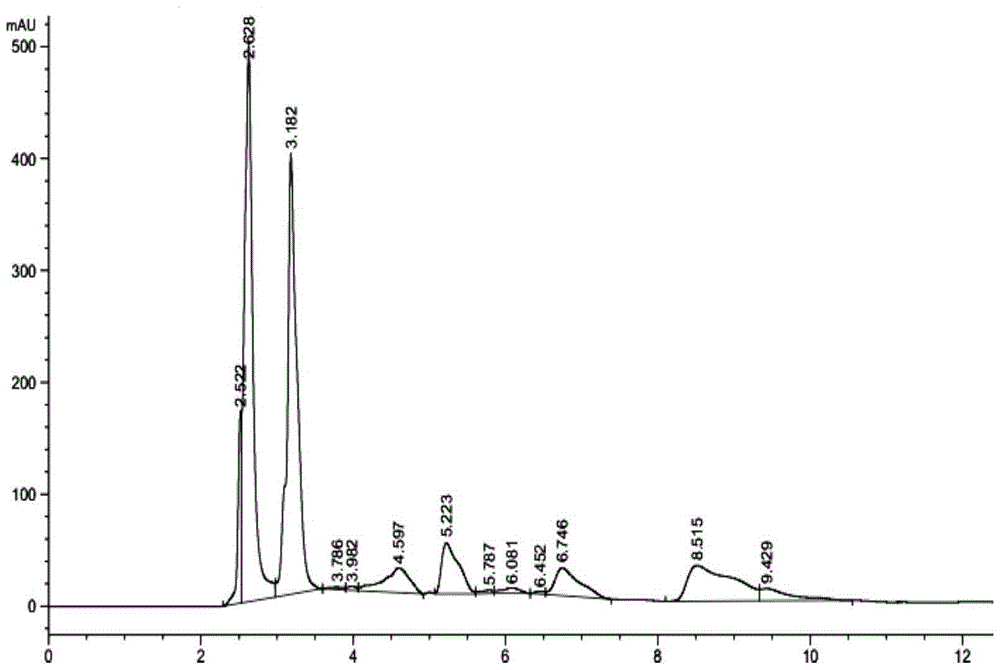

[0033] (2) Enzymatic hydrolysis

[0034] The prepared fish bone homogenate was added with a flavor protease of 2.5% by weight of the fish bone homogenate, and enzymatically hydrolyzed at 50°C for 2.5 hours, the temperature was raised to 95°C, and heated for 15 minutes to inactivate the enzyme to obtain a fish bone enzymatic hydrolysis solution.

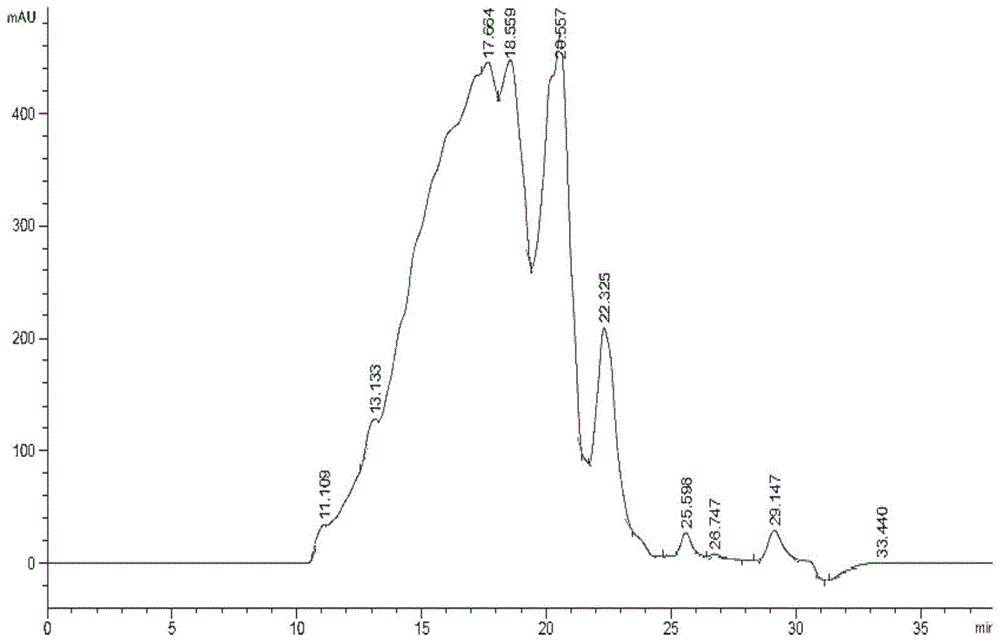

[0035] (3) Fermentation

[0036] Add 1.25% glucose by weight of the enzymatic hydrolysate to the prepared fish bone enzymatic hydrolysate, sterilize at 121°C for 20 minutes, cool to room temperature and mix with cow milk at a mass ratio of 9:1, and 1% by weigh...

Embodiment 2

[0050] After adding the grass carp bone by-products remaining in the processing process to 5 times the volume of the grass carp bone water, it was treated under high pressure at 121°C for 20 minutes to soften the fish bone. Remove the fish meat remaining on the softened fish bones, add 12 times the volume of the fish bones, and then homogenize. The prepared fish bone homogenate was added with a flavor protease of 2.5% by weight of the fish bone homogenate, and enzymatically hydrolyzed at 50°C for 2.5 hours, the temperature was raised to 95°C, and heated for 15 minutes to inactivate the enzyme to obtain a fish bone enzymatic hydrolysis solution.

[0051] Add 1% glucose of the enzymatic hydrolysate to the prepared fish bone enzymatic hydrolysate, sterilize at 121°C for 20 minutes, cool to room temperature and mix with milk at a mass ratio of 3:5, and the mixed solution has activated 1% by weight. The fermented Streptococcus thermophilus, Lactobacillus bulgaricus and Leuconostoc mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com