A kind of nutritious and health-care sorghum cornbread and its processing method

A technology for sorghum and wotou, which is applied in the field of nutrition and health care sorghum wotou and its processing, can solve the problems of small proportion of miscellaneous grains and can not achieve nutritional balance, etc., and achieves the effects of increasing the proportion of miscellaneous grains, reducing cracking, and improving health care value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

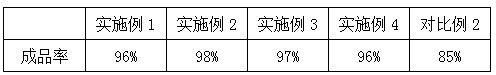

Examples

Embodiment 1

[0029] The preparation method of whole sorghum powder: the sorghum is selected, sieved, removed from impurities, cleaned, dried in a constant temperature drying oven at 60°C for 24 hours, and then crushed through a 100-mesh sieve to obtain whole sorghum flour; Add water to the powder to adjust the water content to 30%, and then feed it into a twin-screw extruder for four-stage extrusion expansion. The four-stage extrusion temperatures are 60°C, 90°C, 110°C, and 120°C, and the feeding speed is 400g. / min, the screw speed is 300r / min. The puffed material is obtained, and the puffed material is superfinely pulverized to 400 meshes to obtain whole sorghum powder.

[0030] Preparation method of honey locust seed extract: crush 10 parts of honey locust seeds, add 5 times the weight of water, heat to 100°C, add 0.1% calcium gluconate, keep warm for 30 minutes, filter to obtain filtrate.

[0031] The processing method of nutrition and health care sorghum steamed bread comprises the f...

Embodiment 2

[0037] The preparation method of whole sorghum powder: the sorghum is selected, sieved, removed from impurities, cleaned, dried in a constant temperature drying oven at 60°C for 24 hours, and then crushed through a 100-mesh sieve to obtain whole sorghum flour; Add water to the powder to adjust the water content to 30%, and then feed it into a twin-screw extruder for four-stage extrusion expansion. The four-stage extrusion temperatures are 40°C, 70°C, 100°C, and 130°C, and the feeding speed is 300g. / min, the screw speed is 200r / min. The puffed material is obtained, and the puffed material is superfinely pulverized to 500 meshes to obtain whole sorghum flour.

[0038] The processing method of nutrition and health care sorghum steamed bread comprises the following steps:

[0039] (1) Raw material processing: Freeze the fresh bean dregs at -20°C for 20 minutes, take them out, place them at 80°C for heat preservation and drying, and crush them to 200 meshes to obtain bean dregs p...

Embodiment 3

[0044] The preparation method of whole sorghum powder: the sorghum is selected, sieved, removed from impurities, cleaned, dried in a constant temperature drying oven at 60°C for 24 hours, and then crushed through a 100-mesh sieve to obtain whole sorghum flour; Add water to the powder to adjust the water content to 30%, and then feed it into a twin-screw extruder for four-stage extrusion and puffing. The four-stage extrusion temperatures are 50°C, 80°C, 110°C, and 140°C, and the feeding speed is 300g. / min, the screw speed is 300r / min. The puffed material is obtained, and the puffed material is superfinely pulverized to 600 meshes to obtain whole sorghum flour.

[0045] The processing method of nutrition and health care sorghum steamed bread comprises the following steps:

[0046] (1) Raw material processing: Freeze the fresh bean dregs at -20°C for 20 minutes, take them out, place them at 80°C for heat preservation and drying, and crush them to 200 meshes to obtain bean dregs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com