A Tidal Flow Constructed Wetland Substrate Filler for Advanced Treatment of Rural Domestic Sewage

A domestic sewage and advanced treatment technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. The effect of low technical requirements, stable operation and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

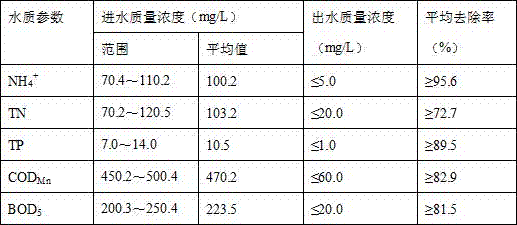

[0019] Example 1 The tested water body is domestic sewage from a certain campus.

[0020] The test device is a simulated cylindrical tidal flow constructed wetland system. The cylinder is made of plexiglass, 130 cm high and 20 cm in inner diameter. Lay 10 cm to 15 cm high gravel, crushed stone and broken brick cushion (containing a small amount of coarse sand) at the bottom of the column. The particle size of gravel, crushed stone and broken brick is 15 to 40 mm; , from top to bottom are equal-volume vermiculite and zeolite mixtures with a height of 45-50 cm, and equal-volume limestone, coal ash, zeolite with a height of 35-40 cm, mixed with an appropriate amount of organic carbon source heated by alkali Material (alkali-heated organic carbon source preparation method: 200 g corn stalks, washed with water to remove dust, shredded, dried at 105°C for 1.5 hours, added NaOH with a mass percentage of 1%, heated at 85°C for 0.9 hours, measured by mass In terms of parts, organic ca...

Embodiment 2

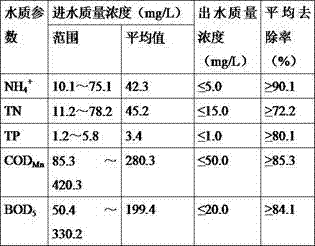

[0025] Example 2 The tested water body is rural domestic sewage treated by septic tanks.

[0026] The test device is a simulated cylindrical tidal flow constructed wetland system. The cylinder is made of plexiglass, 130 cm high and 20 cm in inner diameter. The bottom of the column is paved with 10 cm to 15 cm high gravel and broken brick cushion (containing a small amount of coarse sand). The particle size of gravel and broken bricks is 15 to 40 mm; 35-40 cm equal-volume vermiculite and zeolite mixture, 40-45 cm-high equal-volume limestone, coal ash, zeolite and an appropriate amount of alkali-heated organic carbon source mixture (alkali-heated organic carbon source Mixture preparation method: 150g of straw, washed with water to remove dust, shredded, dried at 105°C for 1.5 hours, added NaOH with a mass percentage of 1%, heated at 85°C for 0.9 hours, in parts by mass, organic carbon source and lye The solid-liquid ratio is 1:25), the particle size is 3-20 mm; the upper layer ...

Embodiment 3

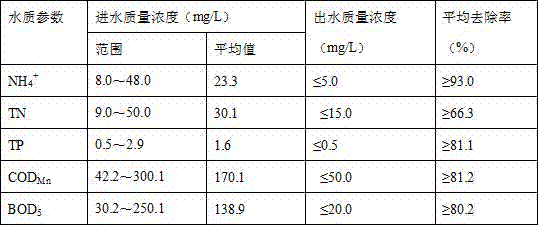

[0031] Example 3 The tested water body is livestock and poultry wastewater after pretreatment and anaerobic digestion in a farm.

[0032]The test device is a simulated cylindrical tidal flow constructed wetland system. The cylinder is made of plexiglass, 130 cm high and 20 cm in inner diameter. A 10 cm to 15 cm high gravel cushion (containing a small amount of coarse sand) is laid on the bottom of the column, and the gravel particle size is 15 to 40 mm; Equal volume of vermiculite and zeolite mixture, equal volume of limestone, coal ash, zeolite and appropriate amount of alkali-heated organic carbon source mixture with a height of 35-40 cm (the preparation method of alkali-heated organic carbon source: reed 200g, Washing and dedusting, drying at 105 °C for 1.5 hours, shredding, adding 1% NaOH by mass, heating at 85 °C for 0.9 hours, in parts by mass, organic carbon source and lye (solid-to-liquid ratio: 1:25), granules The diameter is 3-20 mm; the upper layer is covered with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com