Method for metalizing beryllium oxide ceramic

A beryllium oxide ceramic and metallization technology, which is applied in the field of electronic functional ceramic materials, can solve the problems of unsatisfactory metallization effect, limited printing process, difficult to meet requirements, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

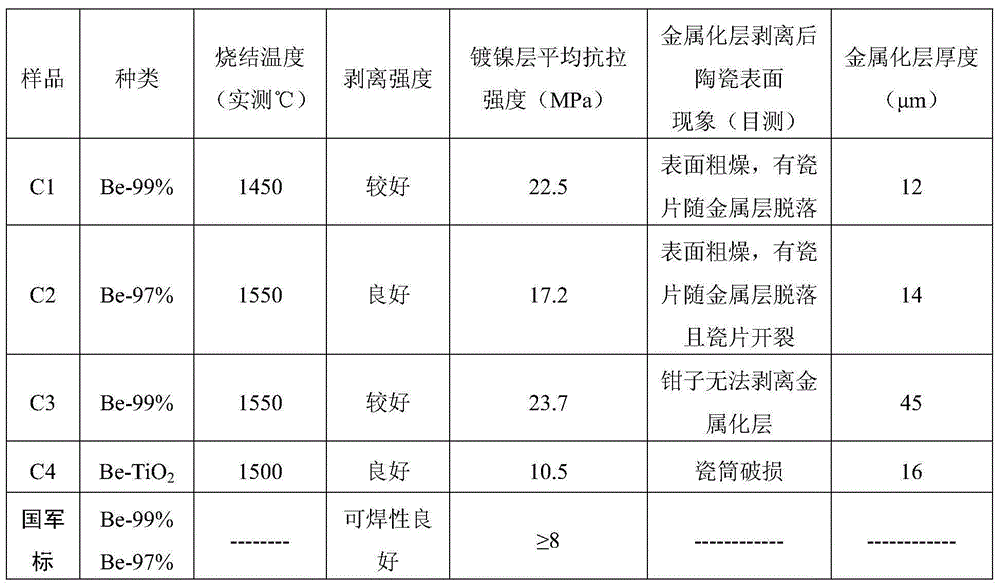

Examples

Embodiment 1

[0054] Take by weighing 500g of alumina, 420g of silicon dioxide, 50g of calcium carbonate and 30g of barium carbonate, put the above-mentioned raw material powder into a ball mill, weigh 1kg of alcohol, Put 2kg of alumina ceramic balls into the ball mill and mill for 12 hours. Pour the slurry into a stainless steel basin, put it in an oven at 80°C, and dry it to make a metallized slurry additive for later use.

[0055] Weigh 2kg of newly purchased tungsten powder, put it into the ball mill, and then put it into Alumina ceramic balls 3kg, alcohol 2kg, wet ball milling for at least 72 hours, take out the ceramic balls with a sieve and dry them for later use.

[0056] Weigh 760g of terpineol, 32g of ethyl cellulose and 8g of castor oil in a jar, put them in an oven at 100°C, bake for 4 hours, stir with a glass rod, and pass through 250 mesh after the ethyl cellulose is completely dissolved. The screen, prepared as adhesive, is poured into a new jar for later use.

[0057] P...

Embodiment 2

[0060] Take by weighing 550g of alumina, 370g of silicon dioxide, 80g of calcium carbonate and 20g of barium carbonate, put the above-mentioned raw material powder into a ball mill, weigh 1kg of alcohol, Add 2 kg of agate ceramic balls into the ball mill and mill for 18 hours. Pour the slurry into a stainless steel basin, put it in an oven at 80°C, and dry it to make a metallized slurry additive for later use.

[0061] Take by weighing prepared metallization slurry additive 80g, manganese powder 40g and embodiment 1 prepared tungsten powder 280g, then add 400g of beryllium oxide ceramic balls were ball-milled in a vibrating ball mill for 8h, and the beryllium oxide ceramic balls were filtered out with a sieve, and the powder was weighed to obtain 392g of metallized powder. Put the metallized powder and 20g of iridium oxide into a mortar, weigh 155g of the binder and mix it with the metallized powder and iridium oxide, stir with a glass rod for 20 minutes, transfer the slurr...

Embodiment 3

[0064] Take by weighing 500g of alumina, 420g of silicon dioxide, 50g of calcium carbonate and 50g of barium carbonate, put the above-mentioned raw material powder into a ball mill, weigh 1kg of alcohol, Add 2 kg of agate balls into the ball mill and mill for 24 hours. Pour the slurry into a stainless steel basin, put it in an oven at 80°C, and dry it to make a metallized slurry additive for later use.

[0065] Take by weighing prepared metallization slurry additive 120g, manganese powder 30g and embodiment 1 prepared tungsten powder 250g, then add 400g of beryllium oxide ceramic balls were ball-milled in a vibrating ball mill for 4 hours, and the beryllium oxide ceramic balls were filtered out with a sieve, and the powder was weighed to obtain 380g of metallized powder. Put the metallized powder and 19g of iridium oxide into a mortar, weigh 148g of the binder and mix it with the metallized powder and iridium oxide, stir with a glass rod for 20 minutes, transfer the slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com