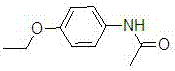

A kind of preparation and crystallization method of phenacetin

A phenacetin and crystallization technology, which is applied in the preparation of organic compounds, carboxylic acid amide preparation, chemical instruments and methods, etc., can solve the problems of expensive bromide high-risk operation, long synthesis cycle, poor product quality, etc. Batch production cycle, short reaction time, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The preparation and crystallization method of phenacetin comprises steps:

[0057] 1) Preparation of p-ethoxyaniline sulfate

[0058] Pump 210L of purified water into a 500L reactor, add 20.6kg of p-ethoxyaniline, control the temperature at 15-20°C, add 16.1kg of sulfuric acid, control the temperature at 15-20°C, and stir for 1 hour to obtain clarified p-ethoxyaniline Aniline Sulfate Sulfate Solution.

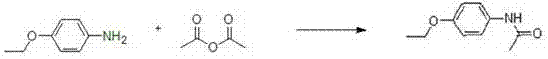

[0059] 2) Preparation of phenacetin

[0060] Heat up the p-ethoxyaniline sulfate solution, control the temperature at 95~100°C, add 17.6kg of acetic anhydride dropwise, add potassium acetate buffer salt to control the pH4~5, control the temperature at 95~100°C and stir for 6 hours, the reaction is over , lowered the temperature to 50°C, slowly added a mixture of 35 L of water and 105 L of isopropanol, stirred at room temperature for 1 hour, and centrifuged and dried to obtain 25.6 kg of crystalline phenacetin with a yield of 95.0% and a purity of 99.3%.

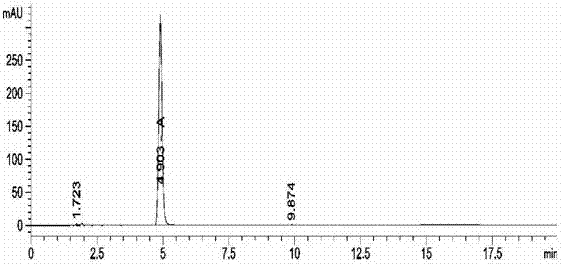

[0061] The l...

Embodiment 2

[0063] The preparation and crystallization method of phenacetin comprises steps:

[0064] 1) Preparation of p-ethoxyaniline phosphate

[0065] Pump 225L of purified water into a 500L reactor, add 20.6kg of p-ethoxyaniline, control the temperature at 15-20°C, add 16.3kg of phosphoric acid, control the temperature at 15-20°C, and stir for 1 hour to obtain clarified p-ethoxyaniline aniline phosphate solution.

[0066] 2) Preparation of phenacetin

[0067] Heat up the p-ethoxyaniline phosphate solution, control the temperature at 95~100°C, add 17.6kg of acetic anhydride dropwise, add ammonium acetate buffer salt to control the pH4~5, control the temperature at 95~100°C and stir for 6 hours, the reaction is over , lowered the temperature to 50°C, slowly added a mixture of 35 L of water and 105 L of isopropanol, stirred at room temperature for 1 hour, and centrifuged and dried to obtain 25.7 kg of crystalline phenacetin with a yield of 95.5% and a purity of 99.2%.

Embodiment 3

[0069] The preparation and crystallization method of phenacetin comprises steps:

[0070] 1) Preparation of bromide salt of p-ethoxyaniline

[0071] Pump 180L of purified water into a 500L reactor, add 20.6kg of p-ethoxyaniline, control the temperature at 30-35°C, add 24.3kg of hydrobromic acid, control the temperature at 30-35°C, and stir for 40 minutes to obtain clarified paraben Oxyaniline bromide salt solution.

[0072] 2) Preparation of phenacetin

[0073] Heat up the p-ethoxyaniline phosphate solution, control the temperature at 90~93°C, add 18.52kg of acetic anhydride dropwise, add calcium acetate buffer salt to control the pH4~5, control the temperature at 90~93°C and stir for 6.5 hours, the reaction is over , lowered the temperature to 45°C, slowly added a mixture of 30L of water and 120L of ethanol, stirred at room temperature for 1 hour, and centrifuged and dried to obtain 25.5kg of crystalline phenacetin, with a yield of 94.7% and a purity of 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com