Preparation of 248 nm deep ultraviolet photoresist film forming resin based on RAFT polymerization method

A technology of deep ultraviolet light and film-forming resin, which is applied in the direction of photosensitive materials, optics, and optomechanical equipment used in optomechanical equipment. And molecular weight, simple polymer structure and other issues, to achieve the effect of increasing light transparency, improving solubility, and broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

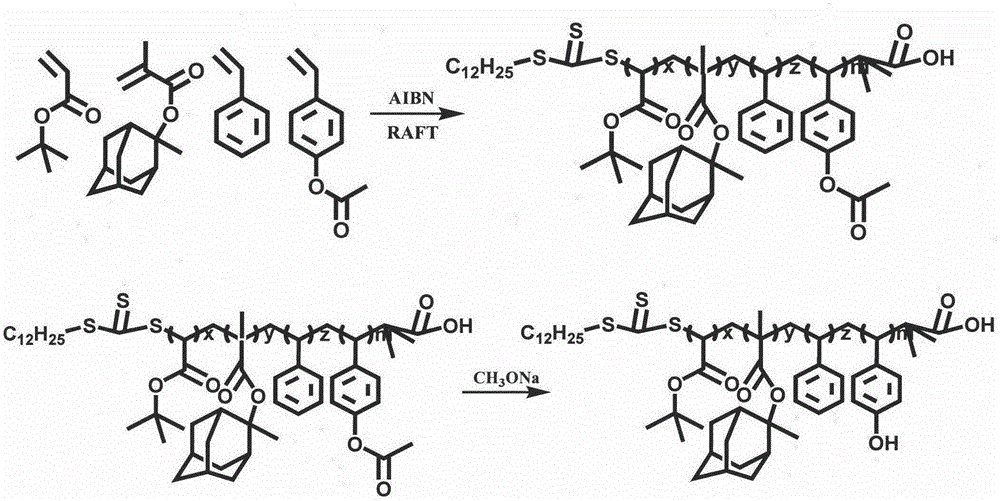

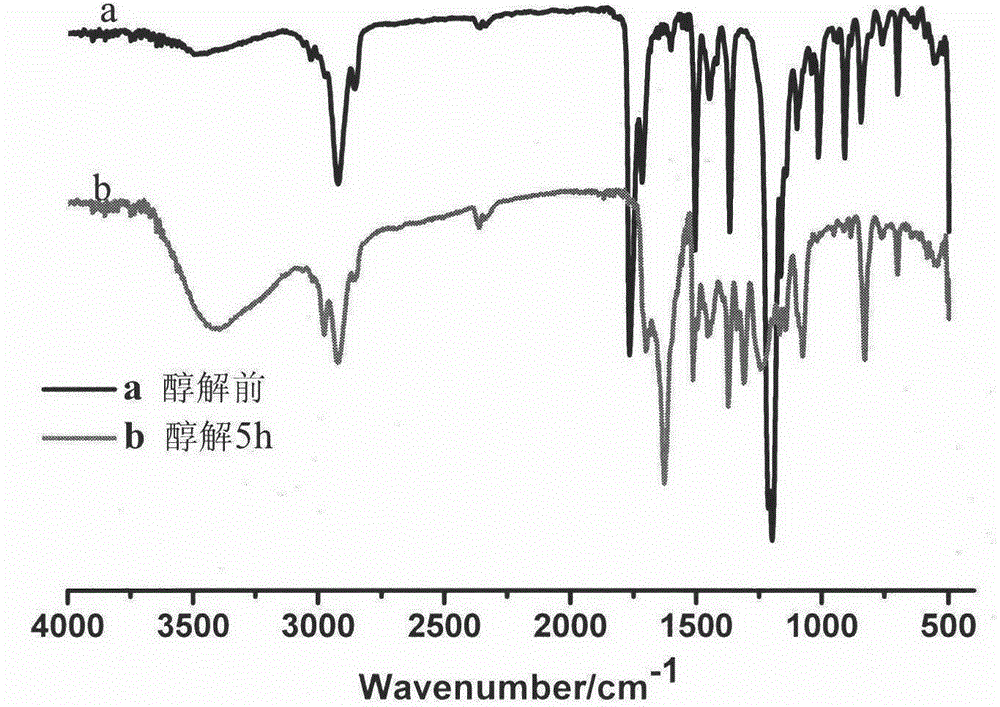

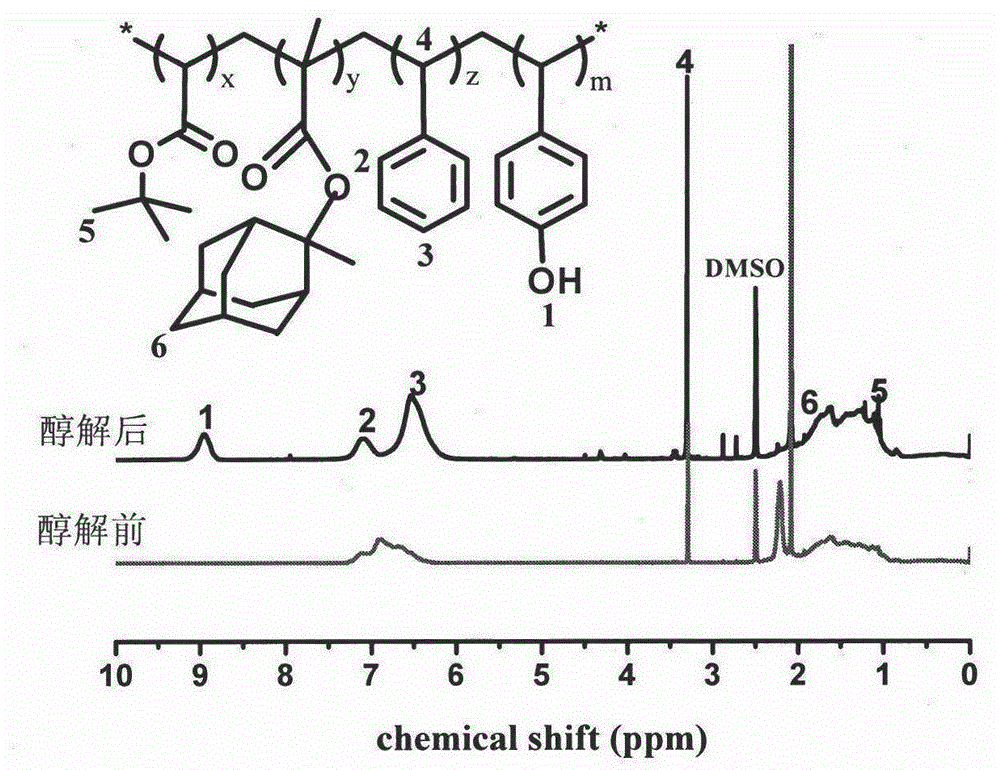

[0016] Synthesis of 248nm photoresist copolymer by RAFT method: according to the proportion of raw materials, add 4.379g p-acetoxystyrene (ASM), 0.937g styrene (St), 0.577g acrylic acid tertiary Butyl ester (TBA), 1.054g 2-methyl-2-adamantyl methacrylate (MAMA), 0.016g azobisisobutyronitrile (AIBN), 0.073g RAFT reagent and 13.06g solvent propylene glycol methyl ether acetate, to Nitrogen was passed through the flask for 30 minutes to remove oxygen, and then sealed, placed in an oil bath at 80°C for 20 hours, then 2.02 g of sodium methoxide and 10 g of methanol were added for alcoholysis for 5 hours, the resulting product was dissolved in acetone, water was used as a precipitant, and the precipitate was dissolved for 3 times. The solid was dried in a vacuum oven at 30°C to obtain a white solid. The RAFT method synthesizes this 248nm copolymer infrared spectrum as figure 2 shown.

[0017] figure 2 The middle a and b are the infrared spectra before and after the alcoholysis ...

Embodiment 2

[0021] Synthesis of 248nm photoresist copolymer by RAFT method: according to the proportion of raw materials, add 4.379g p-acetoxystyrene (ASM), 0.937g styrene (St), 0.577g acrylic acid tertiary Butyl ester (TBA), 1.054g 2-methyl-2-adamantyl methacrylate (MAMA), 0.016g azobisisobutyronitrile (AIBN), 0.1094g RAFT reagent and 13.06g solvent propylene glycol methyl ether acetate, to Nitrogen was passed through the flask for 30 minutes to remove oxygen, and then sealed, placed in an oil bath at 80°C for 20 hours, then 2.02 g of sodium methoxide and 10 g of methanol were added for alcoholysis for 5 hours, the resulting product was dissolved in acetone, water was used as a precipitant, and the precipitate was dissolved for 3 times. The solid was dried in a vacuum oven at 30°C to obtain a white solid. The 248nm copolymer red was synthesized by the RAFT method.

[0022] The preparation and development test of the photoresist composition, the mass percentages of each component are as ...

Embodiment 3

[0025] Synthesis of 248nm photoresist copolymer by RAFT method: according to the proportion of raw materials, add 4.379g p-acetoxystyrene (ASM), 0.937g styrene (St), 0.577g acrylic acid tertiary Butyl ester (TBA), 1.054g 2-methyl-2-adamantyl methacrylate (MAMA), 0.016g azobisisobutyronitrile (AIBN), 0.1458g RAFT reagent and 13.06g solvent propylene glycol methyl ether acetate, to Nitrogen was passed through the flask for 30 minutes to remove oxygen, and then sealed, placed in an oil bath at 80°C for 20 hours, then 2.02 g of sodium methoxide and 10 g of methanol were added for alcoholysis for 5 hours, the resulting product was dissolved in acetone, water was used as a precipitant, and the precipitate was dissolved for 3 times. The solid was dried in a vacuum oven at 30°C to obtain a white solid. The 248nm copolymer red was synthesized by the RAFT method.

[0026] The preparation and development test of the photoresist composition, the mass percentages of each component are as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com